You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bending and flaring road bars for ATB set up - Advice needed

- Thread starter M-Power

- Start date

M-Power

Old School Grand Master

Re: Re:

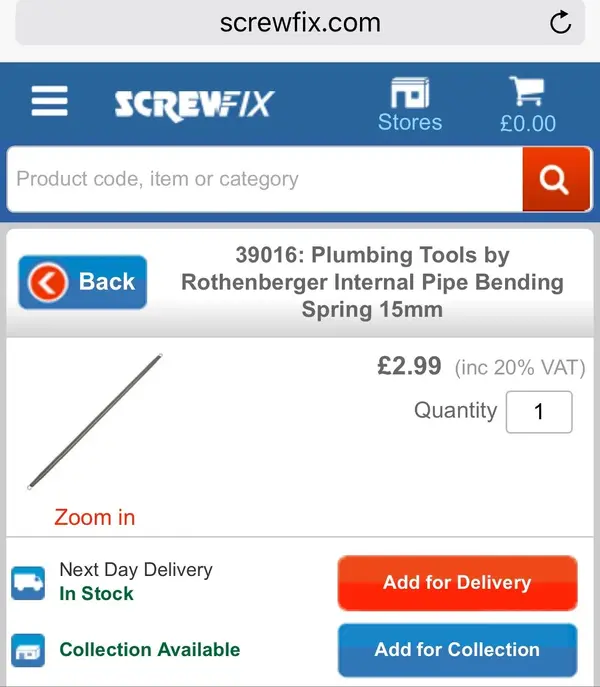

Yeah, I have read a few posts in other threads saying the same but also people used to bend Cinelli bars bitd without issue. I have a nice 80s Cinelli bar and I'm just itching to try it. I will get hold of one of these clamp it up and try to cold set it....see what happens :shock: The other option is to try a motorcycle repair place as they deal with straightening bars a fair bit

531brazed":2tsf4som said:I think youre pushing your luck, may well fatigue alloy, it will snap later

you might get away with bending a steel handlebar, use a pipe bender designed for steel. Better off buying a bar the shape you want

Yeah, I have read a few posts in other threads saying the same but also people used to bend Cinelli bars bitd without issue. I have a nice 80s Cinelli bar and I'm just itching to try it. I will get hold of one of these clamp it up and try to cold set it....see what happens :shock: The other option is to try a motorcycle repair place as they deal with straightening bars a fair bit

Attachments

M-Power

Old School Grand Master

531brazed":2s7ji6v3 said:I doubt it will work, the pipe springs are for soft copper, not standard copper pipe, these days bars are heat treated and tough. Good luck !

You are prolly talking sense :facepalm:

I'd be really wary of doing this. But if I was going to do it, I'd start by annealing the bars, then bending them, and then rehardening them.

Annealing aluminium alloys is pretty easy, clean 'em up, smear them with soap, and then heat them (generally with a brazing torch and a carburising flame) until the soap turns black. When that happens, stop heating allow to cool slowly. You should now have bendy aluminium.

Once you've done with the bending stage, you will need to retemper / harden them. That's a bit more tricksy, as the exact temperatures depend on the alloy in question. It's a two stage process - the first is to heat up to (from memory, for 6061, check these figures before you try, don't quote me, if you destroy your bars or your teeth doing this I'm not responsible yada yada yada) 425°C and then quench in water to room temperature, and the second is a longish (an hour or more) period at 175°C.

Then you mount them on somebody else's bike and let them "break them in".

Annealing aluminium alloys is pretty easy, clean 'em up, smear them with soap, and then heat them (generally with a brazing torch and a carburising flame) until the soap turns black. When that happens, stop heating allow to cool slowly. You should now have bendy aluminium.

Once you've done with the bending stage, you will need to retemper / harden them. That's a bit more tricksy, as the exact temperatures depend on the alloy in question. It's a two stage process - the first is to heat up to (from memory, for 6061, check these figures before you try, don't quote me, if you destroy your bars or your teeth doing this I'm not responsible yada yada yada) 425°C and then quench in water to room temperature, and the second is a longish (an hour or more) period at 175°C.

Then you mount them on somebody else's bike and let them "break them in".

Aluminum doesn't cold set nicely. You will definitely fatigue the metal, and it will crack or snap either now, which is OK but annoying, or later when under load, which is hazardous for your teeth. It's the same reason you don't cold set aluminium frames.

If you're gonna bend aluminium, especially something critical like bars, you really, really, really want to anneal first and harden after. If you don't fancy doing it yourself, you could try finding a local blacksmith / metal worker, who should have everything needed.

Unless, of course, they're a present for somebody you don't like.

Here's some specs for 6061-T6, which is probably what the bars are. Temperatures in overpondian.

http://www.speedymetals.com/information/Material6.html

If you're gonna bend aluminium, especially something critical like bars, you really, really, really want to anneal first and harden after. If you don't fancy doing it yourself, you could try finding a local blacksmith / metal worker, who should have everything needed.

Unless, of course, they're a present for somebody you don't like.

Here's some specs for 6061-T6, which is probably what the bars are. Temperatures in overpondian.

http://www.speedymetals.com/information/Material6.html

M-Power

Old School Grand Master

tufty":1dqgrjy8 said:Aluminum doesn't cold set nicely. You will definitely fatigue the metal, and it will crack or snap either now, which is OK but annoying, or later when under load, which is hazardous for your teeth. It's the same reason you don't cold set aluminium frames.

If you're gonna bend aluminium, especially something critical like bars, you really, really, really want to anneal first and harden after. If you don't fancy doing it yourself, you could try finding a local blacksmith / metal worker, who should have everything needed.

Unless, of course, they're a present for somebody you don't like.

Here's some specs for 6061-T6, which is probably what the bars are. Temperatures in overpondian.

http://www.speedymetals.com/information/Material6.html

Ok, I'm schooled !!! It's been a while since I studied any materials science. Thanks for this Intel Tufty. I will carry on looking for the right bar to show up for sensible money :facepalm: I'd love a wide Salsa Woodchipper in 25.4 !

Case closed methinks..

- Feedback

- View

Bear in mind aluminium doesnt 'just snap', its inert until stress has been applied. This changes the composition of the material, the grain and so on - this can be riding everyday so if you were to do it, I'd use new or unused bars.

Similar threads

- Replies

- 5

- Views

- 366

- Replies

- 54

- Views

- 1K

- Replies

- 10

- Views

- 699