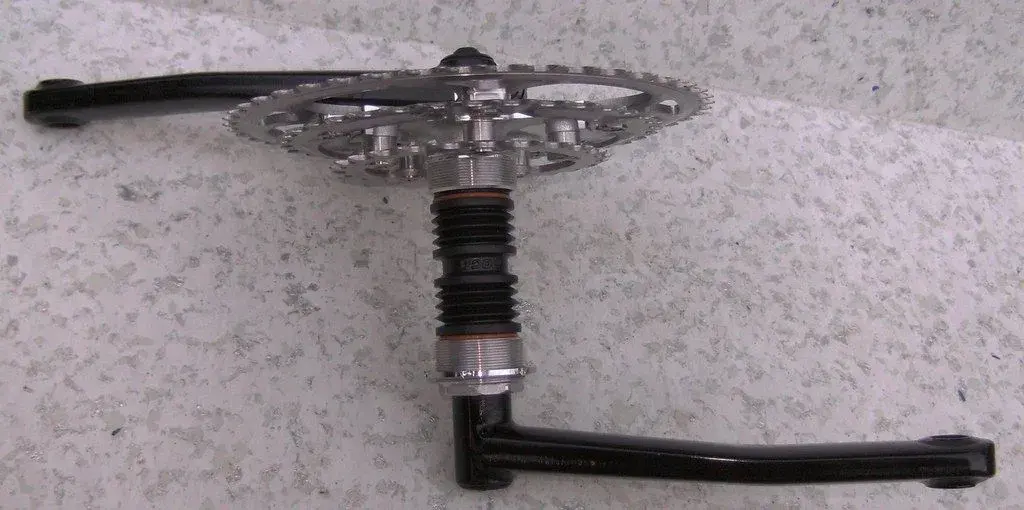

This may sound like a daft question, but just received a nice set of these cranks (nos but with storage marks), but I can't quite figure out how the spider is held on. Has anyone any experience in fitting these that can take me through it?

I was also looking at the bearings in order to get a set for spares, but was surprised at how little contact there is with the axle I.e. to me it is loose and not like fitting an ht2 bb. Is this normal or are the bearings the wrong size?

Last thing - any advice on spares and keeping them on the road. As they are nos, should be ok for now, but would like to know what to do and where to go when the time comes.

Thanks

Ian

I was also looking at the bearings in order to get a set for spares, but was surprised at how little contact there is with the axle I.e. to me it is loose and not like fitting an ht2 bb. Is this normal or are the bearings the wrong size?

Last thing - any advice on spares and keeping them on the road. As they are nos, should be ok for now, but would like to know what to do and where to go when the time comes.

Thanks

Ian