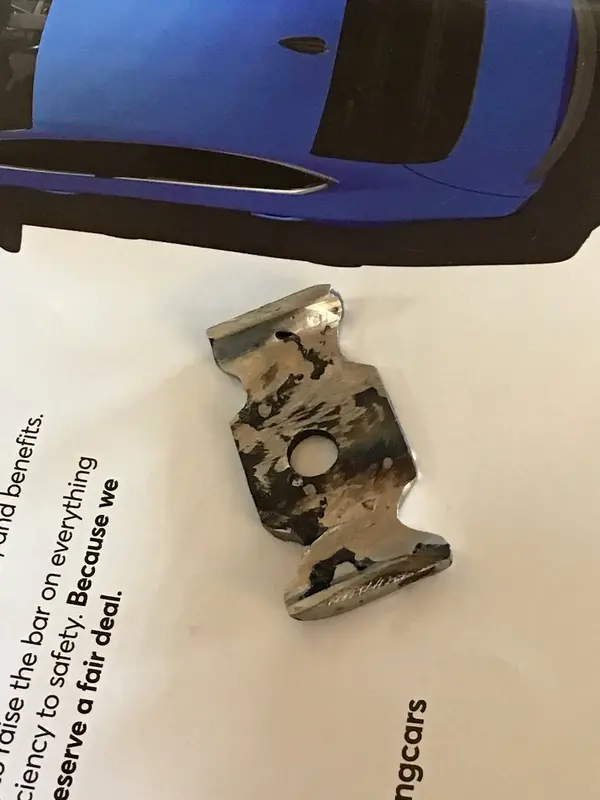

Dr Dremel

Fat Chance Fan

This made me chuckle. Funny, but true!-snip- When it’s wet they accelerate when the brakes are applied. -snip-

This made me chuckle. Funny, but true!-snip- When it’s wet they accelerate when the brakes are applied. -snip-

Yeah, it got so much better when they figured out that machining a brake surface was the way to go.Yeah. I started to shudder already looking at the join in the rim.