You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hack bike

- Thread starter Nabeaquam

- Start date

Nabeaquam

BoTM Winner

I don’t think it’s got so much to do with skills. It’s more down to patients, work space, imagination and tools. I need more tools to do better job. Some tools you can make, some you can’t and sometimes there’s an alternative, which is seldon as good as the real thing but it beats having nothing.How to do pandemic- RetroBike edition

Loving this and wish I had the skills to "hack" something like this together.

Nabeaquam

BoTM Winner

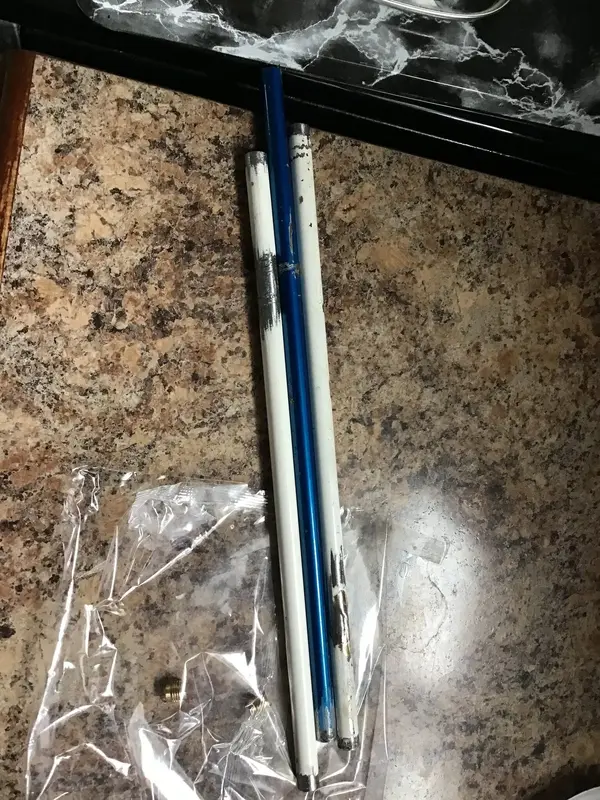

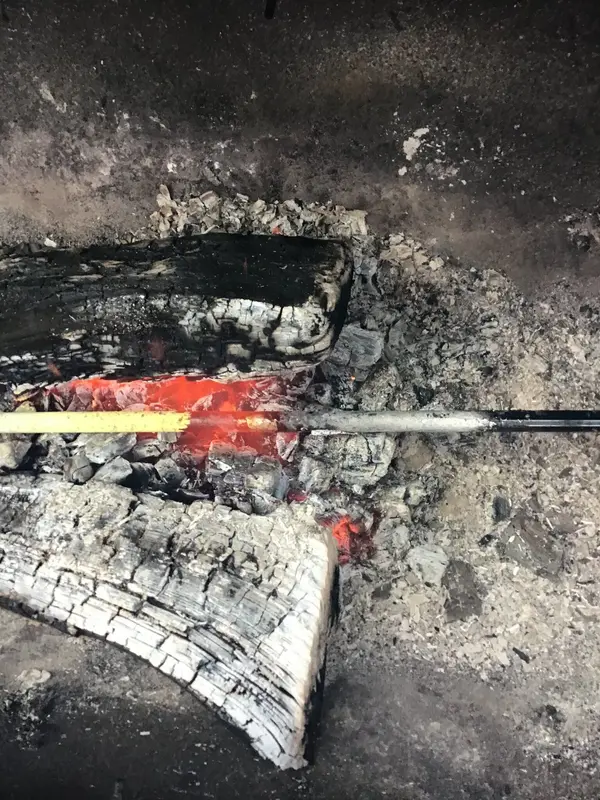

I’m making another Breezer 1 hack bike frame. I don't have another mixte to donate the laterals and now even my preferred big box cheap ones are too expensive to hack up. I cut three seat post stays off old bikes that have the right diameter. I threaded the inside of the seat stays and screwed in $1.19 brass nipples that had melted brazing flux on them. I clamped them in angle iron and tack welded the joints. I put the 3 joined pieces in my smoker with a small hardwood fire. It’s -20C and blowing from the north so I added heat by blowing air and propane on the joint and when it was red hot. I sprinkled brazing flux on the hot joint.

The brass brazing rod easily melted with propane torch assist. This would be easier in the summer with a much bigger fire as no torch would be required. Hack bike furnace brazing. Will it hold when flat filed?

The brass brazing rod easily melted with propane torch assist. This would be easier in the summer with a much bigger fire as no torch would be required. Hack bike furnace brazing. Will it hold when flat filed?

The brass brazing rod easily melted with propane torch assist. This would be easier in the summer with a much bigger fire as no torch would be required. Hack bike furnace brazing. Will it hold when flat filed?

The brass brazing rod easily melted with propane torch assist. This would be easier in the summer with a much bigger fire as no torch would be required. Hack bike furnace brazing. Will it hold when flat filed?

Last edited:

Thias

Klein Fan

Lovin't it. You're a hero.

I do my own bike parts. Brakes and Hubs and stuff. Wasn't able to make my own frames yet. I can't weld. But I bought a defective welder. Whenever I get around fixing it, first thing I will try to make is a hack bike for sure.

Your thread is a great motivator for me to get started.

Keep us posted.

I do my own bike parts. Brakes and Hubs and stuff. Wasn't able to make my own frames yet. I can't weld. But I bought a defective welder. Whenever I get around fixing it, first thing I will try to make is a hack bike for sure.

Your thread is a great motivator for me to get started.

Keep us posted.

Nabeaquam

BoTM Winner

I also bought an old unworking welder at an estate sale. I had it for many years until one of my buddies helped me disassemble it and fix it. It was very dirty and dusty inside and we used a shop vac and blower before we could see what was what. Get a good self darkening helmet, 100 pounds at least. Years ago I built a hack bike using battery welding, house wires for wiring the two batteries in parallel, house wiring for the ground and stinger leads. I used vice grips to hold the wiring to the batteries and for the ground and stinger clamps. All you need are two 12 volt car batteries. They need frequent charging. I only use 6011 electrodes as I don’t weld enough to learn how to use them all well. I also have a mig welder.Lovin't it. You're a hero.

I do my own bike parts. Brakes and Hubs and stuff. Wasn't able to make my own frames yet. I can't weld. But I bought a defective welder. Whenever I get around fixing it, first thing I will try to make is a hack bike for sure.

Your thread is a great motivator for me to get started.

Keep us posted.

Nabeaquam

BoTM Winner

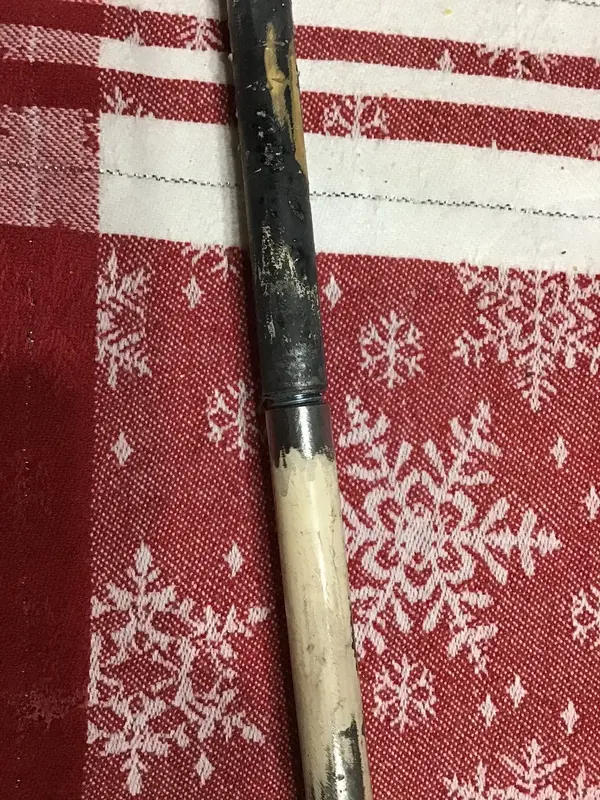

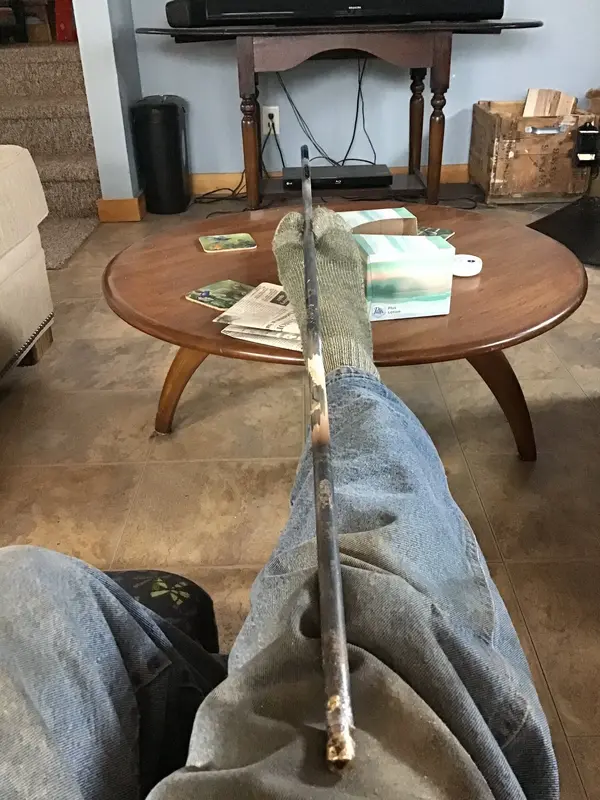

It’s flat filed and still together. I’m not going to bother with a finer file yet, until I build the second lateral. I don’t want to spend a lot of time finishing until I see if this hair brained project pans out. Can I make two that don’t fall apart?

For my next joint I’m going to use a cut off steel bolt screwed into the threaded pipe. That way, instead of doing a bridge tack across the joint, I can drill a hole through the pipe and slightly into the bolt and do a plug weld on each side of the joint. The two welds button top can be filed off and then I’ll braze fill the joint. This should be easier. Below, threaded pipe with a very short bolt section used as a bridge. In the first photo it’s not screwed tight. I’ll have to wait until next week to braze fill this joint as it has been cold, -18C today.

For my next joint I’m going to use a cut off steel bolt screwed into the threaded pipe. That way, instead of doing a bridge tack across the joint, I can drill a hole through the pipe and slightly into the bolt and do a plug weld on each side of the joint. The two welds button top can be filed off and then I’ll braze fill the joint. This should be easier. Below, threaded pipe with a very short bolt section used as a bridge. In the first photo it’s not screwed tight. I’ll have to wait until next week to braze fill this joint as it has been cold, -18C today.

Last edited:

Nabeaquam

BoTM Winner

The ends screwed together, clamped straight and holes drilled through the tubing and into the very short bolt section. The drilled holes are right at the end of the cut off bolt section that’s threaded into the tubes.

The drilled holes filled with welding, called a plug weld. It’s super strong. When it gets warmer and calm I’ll fill the gap by more furnace brazing.

The drilled holes filled with welding, called a plug weld. It’s super strong. When it gets warmer and calm I’ll fill the gap by more furnace brazing.

Nabeaquam

BoTM Winner

Hay, Guy’s and Gals, I just found a photo of my first hack bike. A klunker mountain bike. I made it 7 years ago by cutting up several bikes. The front triangle was from a woman’s bike where one of the down tubes was cut off and made into one of the top tubes (a gender bender). The rear triangle was made from two other bikes. The front and rear brakes are coaster brakes and the front one hardly worked (not enough leverage from hand levers , I tried several). The curved top tube was bent by filling it with sand, throwing it into a fire pit and bending it over a junk car rim. It was battery welded together using 2 twelve volt car batteries. A small amount of the welding was done using coat hangers, just so I could say it was welded up using coat hanger wire. I thought I could save vintage frames from becoming klunkers by making my own, ha. The seat post was a homemade gallows or lucky 7 to get the seat back. The grips are made from red rubber heater hose with wine corks jammed in the bar ends. A real piece of folk art. To keep the hack theme going it was painted with a bench broom. I rode it most of the summer but the frame broke just before a race I was planning to run it in. It broke because the seat tube was butt welded and the seat post was sitting against the butt weld, poor thinking on my part.

Here it’s remains sit today, they call this section of the local Epic Route the Rusty Bike Trail.

Here it’s remains sit today, they call this section of the local Epic Route the Rusty Bike Trail.

Last edited:

Similar threads

- Replies

- 8

- Views

- 519