MikeD

Senior Retro Guru

I was about to suggest exactly the opposite  If the adapter contacted the whole top edge of the dropout and the lower part of the seatstay it'd spread the load out more. As it is, everything's going into a fairly small area on the stay. I know it's shared across both stays but unless it's a perfect fit one's going to see more than the other. I think more surface area would be safer.

If the adapter contacted the whole top edge of the dropout and the lower part of the seatstay it'd spread the load out more. As it is, everything's going into a fairly small area on the stay. I know it's shared across both stays but unless it's a perfect fit one's going to see more than the other. I think more surface area would be safer.

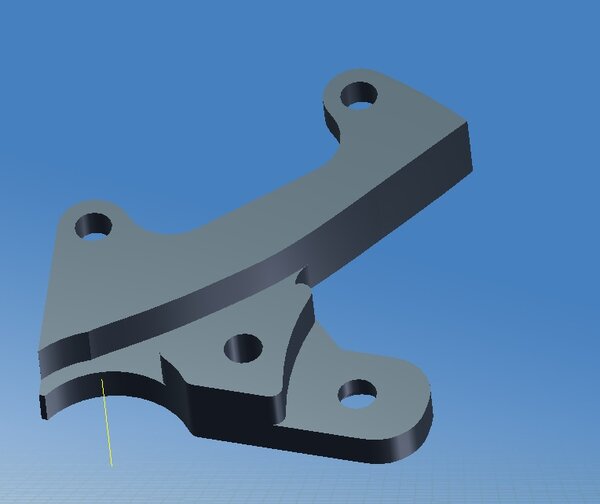

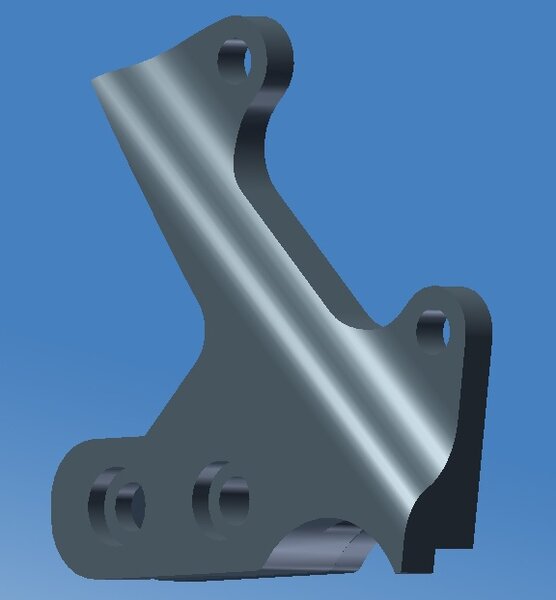

Here's the mount off my old Mountain Cycle Moho, which interlocked with the seat/chainstays and dropout and bolted into existing holes. The funny-shaped bit between the actual brake mount holes was an exact fit with the shape of the stay. Pic of it in place is a bit tiny, can't find a better one

Here's the mount off my old Mountain Cycle Moho, which interlocked with the seat/chainstays and dropout and bolted into existing holes. The funny-shaped bit between the actual brake mount holes was an exact fit with the shape of the stay. Pic of it in place is a bit tiny, can't find a better one