Martini-night

Dirt Disciple

Hello, I've got a couple of summer projects,several retro frames to build.

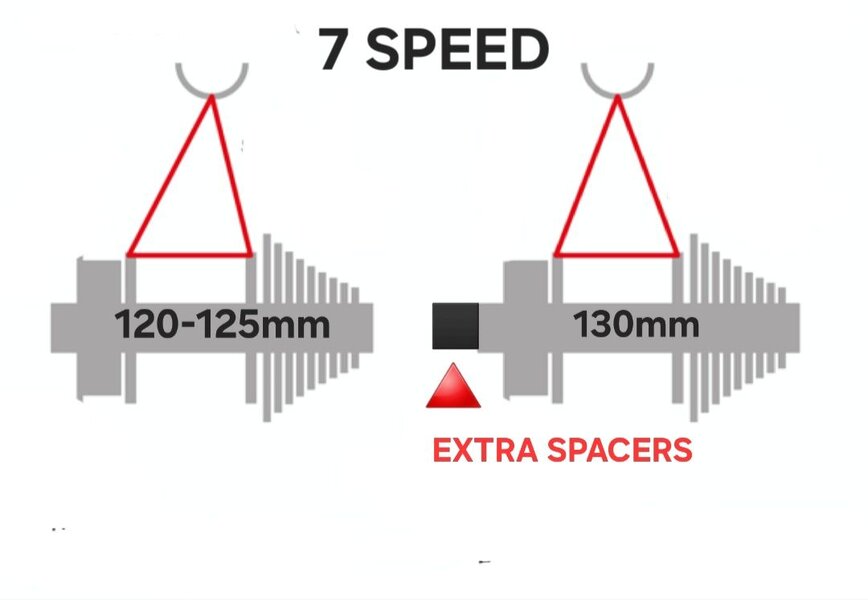

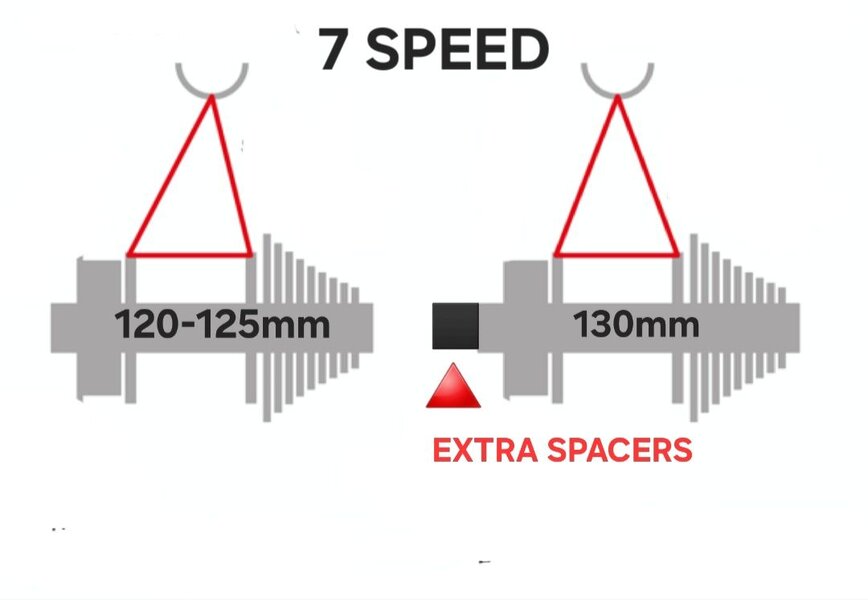

Regarding the rear wheel building/lacing with 7 speed cassete ; does the picture apply to the frames with wider and lower space between the dropouts??

-I've got 2 frames, a 122mm and a 127mm spaced frames and i was about to start lacing/ building the rear wheels(1991 shimano Exage hubs),but I'm quite confused how should i lace.

- All my retro complete bikes here are the same on the right picture.

just wondering about the smaller 124mm frame I've got...

Regarding the rear wheel building/lacing with 7 speed cassete ; does the picture apply to the frames with wider and lower space between the dropouts??

-I've got 2 frames, a 122mm and a 127mm spaced frames and i was about to start lacing/ building the rear wheels(1991 shimano Exage hubs),but I'm quite confused how should i lace.

- All my retro complete bikes here are the same on the right picture.

just wondering about the smaller 124mm frame I've got...

Last edited: