About the same age as Master Yoda I think.Midlife":2i8eljxe said:How old is Dave Yates?

Shaun

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dave Yates Frame Building Course

- Thread starter originalshinkicker

- Start date

originalshinkicker

rBotM Winner

Midlife":32w8e49k said:Hmmmm, never thought if that. My bedroom is over our garage

Would love to build a 70's style TT frame as a sibling to my originals....might have to wait until I retire which is 10 plus years away or treat myself as a 60th birthday present in 5 years time. How old is Dave Yates?

Shaun

Not too sure Shaun; I would hazard a guess that he is early to mid 60s based on what we were talking about today.

He was talking about Chas Roberts today who is currently taking a break from frame building for a little while but may come back doing a similar thing to Dave with running courses.

curzons246

Retro Guru

Tubes and lug id

Hi do you mind if I ask which tube set and which lugs you've built your frame with. Cheers Bill

Hi do you mind if I ask which tube set and which lugs you've built your frame with. Cheers Bill

originalshinkicker

rBotM Winner

Re: Tubes and lug id

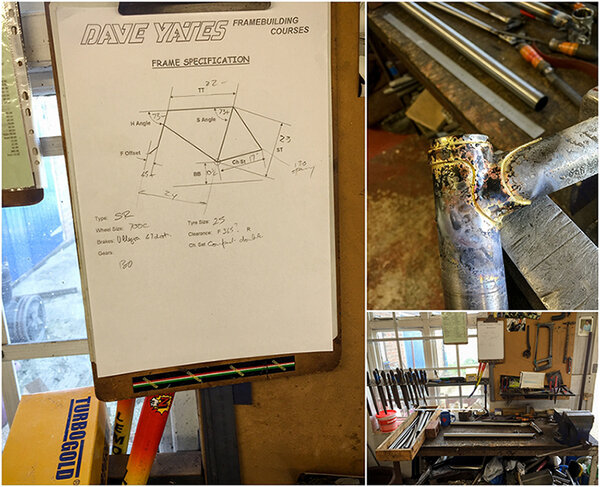

Hi Bill. First thing you do is chat with Dave about the type of bike you want and the riding you will be doing. He will consider what tubes you need. For me, he has advised 631 main tubes, 525 rear stays. The lugs and BB are good quality cast lugs. I'm building for mudguards and a rear rack so am using some cast dropouts with eyes already fitted.

curzons246":2dkcuolq said:Hi do you mind if I ask which tube set and which lugs you've built your frame with. Cheers Bill

Hi Bill. First thing you do is chat with Dave about the type of bike you want and the riding you will be doing. He will consider what tubes you need. For me, he has advised 631 main tubes, 525 rear stays. The lugs and BB are good quality cast lugs. I'm building for mudguards and a rear rack so am using some cast dropouts with eyes already fitted.

originalshinkicker

rBotM Winner

Day 2 started with a little bit of measuring to get the frame tube lengths and angles written down. Yesterday didn't involve anything critical, but to put the main triangle together, we needed to know measurements. The top head tube lug I brazed last thing yesterday was looking ok.

First thing to do today was cut the mitres on the down tube/head tube joint. Also a slight modification to the web on the back of the BB. We cut it off and shortened the lug tips so that we could fit a bridge in the chain stays for the mudguards.

Dave had to do a little modification to the seat lug for his jig so while he was on doing that, I had a look at the frames hanging up. Max, one of Dave's dogs has a snug spot right next to one of the work benches.

It was over to the jig to start putting the sub assemblies together. Head tube length is set based on fork design. Chain stays are cut to length and set in the jig to the correct OLN.

Dave has a process to which joints get brazed in which order. While one joint cools down, another is done. The head lugs are so difficult as there is a huge area to get the brass to flow into. The seat lug was even harder. It is a huge chunk of metal that needs lots of heat but not enough heat that you are going to blow a hole in a tube!

With the head tube, seat lug and BB fully brazed, it was time to cut seat stays. A slot cut into the bottom for the drop out with a scallop filed into it. The other end was cut at an angle ready for a flat plate (almost like an oversized seat stay cap on a Raleigh). The two ends of the seat stays should hopefully work out the same length if they've been cut properly.

So the frame is almost ready to come out of the jig. I just have to attach the seat stays to the side of the seat lug and fit the end caps. It can then come out of the jig. The 2 bridges and whatever braze-ons I want can then be fitted.

Another brilliant day chatting with Dave. He and Joe Waugh Owned M.Steels in Gosforth and I worked at Denton Cycles just a couple of miles down the road in Newcastle at the same time, so lots of similar stories and names are coming up

I should start on building forks tomorrow.

First thing to do today was cut the mitres on the down tube/head tube joint. Also a slight modification to the web on the back of the BB. We cut it off and shortened the lug tips so that we could fit a bridge in the chain stays for the mudguards.

Dave had to do a little modification to the seat lug for his jig so while he was on doing that, I had a look at the frames hanging up. Max, one of Dave's dogs has a snug spot right next to one of the work benches.

It was over to the jig to start putting the sub assemblies together. Head tube length is set based on fork design. Chain stays are cut to length and set in the jig to the correct OLN.

Dave has a process to which joints get brazed in which order. While one joint cools down, another is done. The head lugs are so difficult as there is a huge area to get the brass to flow into. The seat lug was even harder. It is a huge chunk of metal that needs lots of heat but not enough heat that you are going to blow a hole in a tube!

With the head tube, seat lug and BB fully brazed, it was time to cut seat stays. A slot cut into the bottom for the drop out with a scallop filed into it. The other end was cut at an angle ready for a flat plate (almost like an oversized seat stay cap on a Raleigh). The two ends of the seat stays should hopefully work out the same length if they've been cut properly.

So the frame is almost ready to come out of the jig. I just have to attach the seat stays to the side of the seat lug and fit the end caps. It can then come out of the jig. The 2 bridges and whatever braze-ons I want can then be fitted.

Another brilliant day chatting with Dave. He and Joe Waugh Owned M.Steels in Gosforth and I worked at Denton Cycles just a couple of miles down the road in Newcastle at the same time, so lots of similar stories and names are coming up

I should start on building forks tomorrow.

Attachments

-

Dave Yates Frame Building Course Day 2 Start.jpg96.1 KB · Views: 590

Dave Yates Frame Building Course Day 2 Start.jpg96.1 KB · Views: 590 -

Dave Yates Frame Building Course Day 2 Cutting Downtube Head tube mitre.jpg93.3 KB · Views: 590

Dave Yates Frame Building Course Day 2 Cutting Downtube Head tube mitre.jpg93.3 KB · Views: 590 -

Dave Yates Frame Building Course Day Dave Doing Some Grinding.jpg104.9 KB · Views: 590

Dave Yates Frame Building Course Day Dave Doing Some Grinding.jpg104.9 KB · Views: 590 -

Dave Yates Frame Building Course Day 2 Getting things in the Jig.jpg110.7 KB · Views: 590

Dave Yates Frame Building Course Day 2 Getting things in the Jig.jpg110.7 KB · Views: 590 -

Dave Yates Frame Building Course Day 2 Brazing Main Triangle.jpg93.6 KB · Views: 590

Dave Yates Frame Building Course Day 2 Brazing Main Triangle.jpg93.6 KB · Views: 590 -

Dave Yates Frame Building Course Day 2 Creating Seat Stay Ends.jpg106.2 KB · Views: 590

Dave Yates Frame Building Course Day 2 Creating Seat Stay Ends.jpg106.2 KB · Views: 590 -

Dave Yates Frame Building Course Day 2 Seat Stays Prepped and Ready to Fit.jpg99.5 KB · Views: 590

Dave Yates Frame Building Course Day 2 Seat Stays Prepped and Ready to Fit.jpg99.5 KB · Views: 590

- Feedback

- View

Nice. What inside leg are you then?

originalshinkicker

rBotM Winner

The History Man":3pvtoe4c said:Nice. What inside leg are you then?

6ft with a 32 1/4" inside leg with a shorter body than legs. I always feel like I'm stretching to the bars so we are building with a shorter than normal toptube but still long enough to keep the front long enough to not cause issues with mudguard/pedal clearance. Should be set up with a 9cm stem.

xxnick1975

Old School Grand Master

- Feedback

- View

Great insights here, Dave must be 65/66.

Lovely frame coming to life there

Lovely frame coming to life there

Similar threads

- Replies

- 31

- Views

- 2K

- Replies

- 21

- Views

- 1K

- Replies

- 2

- Views

- 795