Finally got round to starting my 92 team marin project. Its been on the back buner as whilst its nice weather, im normally riding the days im now not back in gainful employment!

Also, tbh, its taken me a good while (a year) to work out exactly where i want to go with it. I've got zero interest in a catalogue version as I hate green paint. Plus, tbh, there is absolutely no way I could ride a catalogue bike for more than 30mins without being crippled.....so as a daily driver that's a non starter.

So, Im building using stuff I love and have rated throughout the years. Most period (more by luck then design).

Im also leaning heavily on what I learnt from my " bike I should be riding" build last year. Which turned out a fantastic tourer, I've really enjoyed in cosseted comfort .

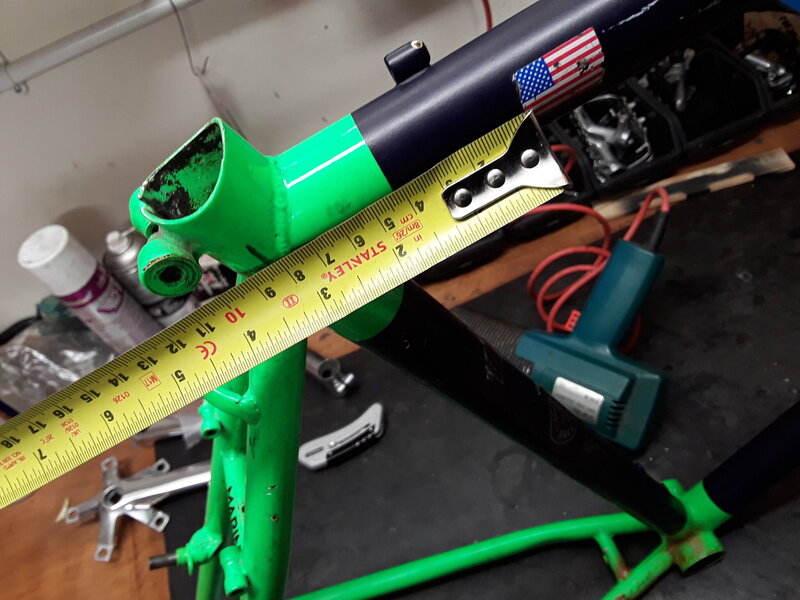

So here's the wreckage that turned up tail end of last year....

Also, tbh, its taken me a good while (a year) to work out exactly where i want to go with it. I've got zero interest in a catalogue version as I hate green paint. Plus, tbh, there is absolutely no way I could ride a catalogue bike for more than 30mins without being crippled.....so as a daily driver that's a non starter.

So, Im building using stuff I love and have rated throughout the years. Most period (more by luck then design).

Im also leaning heavily on what I learnt from my " bike I should be riding" build last year. Which turned out a fantastic tourer, I've really enjoyed in cosseted comfort .

So here's the wreckage that turned up tail end of last year....

Last edited: