Even a tiny hobby grade 3D printer should be able to knock one out in an hour, might need a bit of finishing though!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Syncros angle/slanted stem cap alternative

- Thread starter RockiMtn

- Start date

dongward":30ozp2w1 said:jax13":30ozp2w1 said:https://www.thingiverse.com/search?q=Syncros&type=things&sort=relevant

Would this be worth a shot?

I've got a 3d printer sitting idle here at the moment and am happy to print a few for the forum and send them out to see if they work / hold up.

I would say so - the latter Syncros caps were plastic so it should work... also blue ano syncros stem...? It would be interesting to see how long it took/how much material to be able to gauge a cost for production and P+P.

D

p.s. interesting find!

I'll throw a few put tonight once I've put the boy to bed.

Anyone who wants to trial one, pm me with an address and I'll send one through because I dokt think I've got my syncros stem anymore

jax13":24eg74er said:dongward":24eg74er said:jax13":24eg74er said:https://www.thingiverse.com/search?q=Syncros&type=things&sort=relevant

Would this be worth a shot?

I've got a 3d printer sitting idle here at the moment and am happy to print a few for the forum and send them out to see if they work / hold up.

I would say so - the latter Syncros caps were plastic so it should work... also blue ano syncros stem...? It would be interesting to see how long it took/how much material to be able to gauge a cost for production and P+P.

D

p.s. interesting find!

I'll throw a few put tonight once I've put the boy to bed.

Anyone who wants to trial one, pm me with an address and I'll send one through because I dokt think I've got my syncros stem anymore

Seeing as how no one has stepped up to try this ( I'm assuming), I will throw my hat in the ring - I was only hesitant as my stem is up in Skye and I'm in Edinburgh... but I will be up there in the next few weeks. I have a 1" 1/8 hinge fron cattle prod that's been religated to the parts bin due to the original plastic wedge imploding and finding the bucket in a rage... I'll PM you an address the now

- Feedback

- View

I tend to use round ones that can take a bolt not going straight down or better the old deep aheadset/diacomp/.. plastic ones work fine.

They may not look as tidy, but the style that are flat and round are not much better (they have Syncros etched into them). but they are much stronger than the naff sycnros plastic things they made.

That links not working for me, but if it's the one I think it is, then the recess is nice, the top just needs to be made felt with either a normal bolt or the later countersunk bolt design. I never got around to trying it.

I do have originals, but you know, never find them when you need them.

to be honest, once bolted down with a normal topcap or similar to get the compressing, a push in fake on will be fine and dandy.

The best upgrade for Sycnros stems are the later 'GT' era twin clamp and push bit style cinches.

They may not look as tidy, but the style that are flat and round are not much better (they have Syncros etched into them). but they are much stronger than the naff sycnros plastic things they made.

That links not working for me, but if it's the one I think it is, then the recess is nice, the top just needs to be made felt with either a normal bolt or the later countersunk bolt design. I never got around to trying it.

I do have originals, but you know, never find them when you need them.

to be honest, once bolted down with a normal topcap or similar to get the compressing, a push in fake on will be fine and dandy.

The best upgrade for Sycnros stems are the later 'GT' era twin clamp and push bit style cinches.

Re:

The file in question has a dished top and not a proper countersink recess but it shouldn't take much to tweak it in a cad program to have a proper (and strong enough) countersink to take a proper bolt.

Getting the angle and diameter dialled in is the key.

Once that's sorted I'll play with the top & make a batch of 'retrobike' embossed ones and run a big batch off of somebody who is a bit more active on the forum wants to go 50/50 on the deal with me and I'll send batches to them to sell individually.

The file in question has a dished top and not a proper countersink recess but it shouldn't take much to tweak it in a cad program to have a proper (and strong enough) countersink to take a proper bolt.

Getting the angle and diameter dialled in is the key.

Once that's sorted I'll play with the top & make a batch of 'retrobike' embossed ones and run a big batch off of somebody who is a bit more active on the forum wants to go 50/50 on the deal with me and I'll send batches to them to sell individually.

Re:

The main issue was strength, if they had adequate torque in them they started to delaminate, I suppose this could be avoided by printing them vertically but that has its own implications.

Printing in abs would potentially help a lot as it is a physically stronger plastic but without making them overly large and clunky looking, the strength I'd want from them just isn't there unfortunately.

The main issue was strength, if they had adequate torque in them they started to delaminate, I suppose this could be avoided by printing them vertically but that has its own implications.

Printing in abs would potentially help a lot as it is a physically stronger plastic but without making them overly large and clunky looking, the strength I'd want from them just isn't there unfortunately.

- Feedback

- View

I'd just like some cheap reproductions in all three sizes of the proper metals ones.

viewtopic.php?f=1&t=300948

Unfortunately, I don't think that will actually be cheap.

viewtopic.php?f=1&t=300948

Unfortunately, I don't think that will actually be cheap.

Re: Re:

That looks like one of the ones I made years ago.

Gerard":3iokqblk said:I have the same dilemma re stem cap. :facepalm:

In my search I found this. It seems even Syncros made adapters to take a regular cap which they were sending out! Not attractive....but does the job.

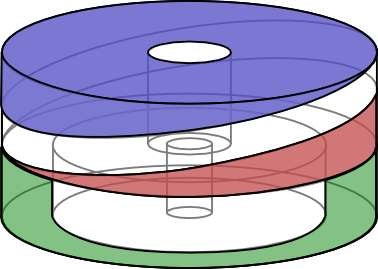

I think I'll do the same....though I can't believe it would be difficult to machine one up. As one chap on a forum pointed out:It's a three step job, creating the base in a lathe (green), the next sawing the top (blue) in the correct angle and lastly 'manually' adapting the top (red)

That looks like one of the ones I made years ago.

kokies

Retro Guru

Here is our take on the angled top caps. CNCed from 6061 in anodized silver, black and matte black, in 1 1/8" and 1". They will be available on our site later this week. Titanium bolt included of course.

https://specialtyretroproducts.com/product-category/syncros/

https://specialtyretroproducts.com/product-category/syncros/

Attachments

Similar threads

- Replies

- 61

- Views

- 20K

- Replies

- 68

- Views

- 20K