Let's discuss the dreaded Syncros "slanted" stem cap we love to hate. Why hate? Because no other company used/made them, and if lost or broken… good luck finding a replacement/substitute. :facepalm: And before anyone chimes in, yes i know someone has made some reproductions ones now.

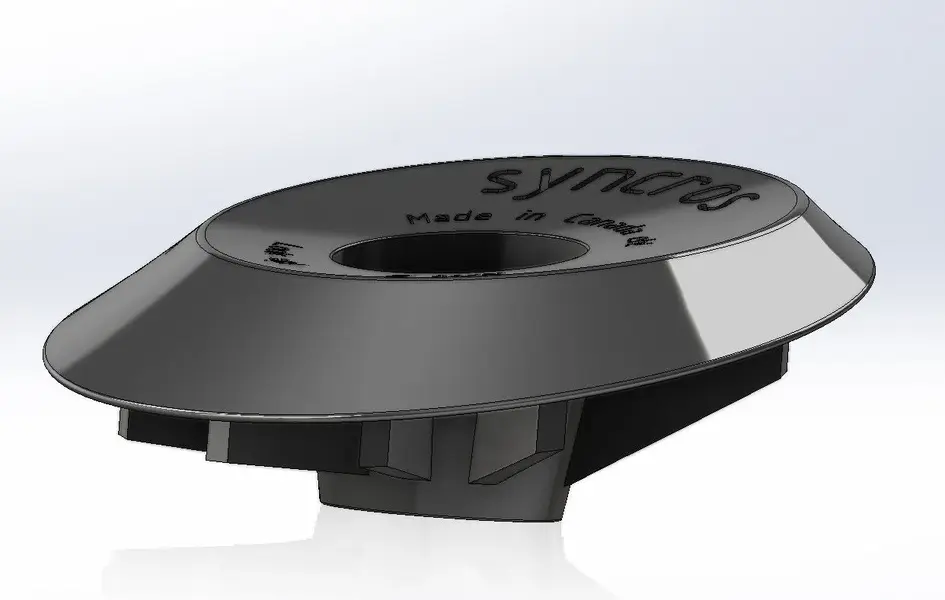

So I've seen and have owned three variants of these. The typical and most prone to over-tightening and cracking are the plastic ones. Second and less common are the cast metal ones. I like the fact that they are metal, but I like the look/design of the plastic ones better.

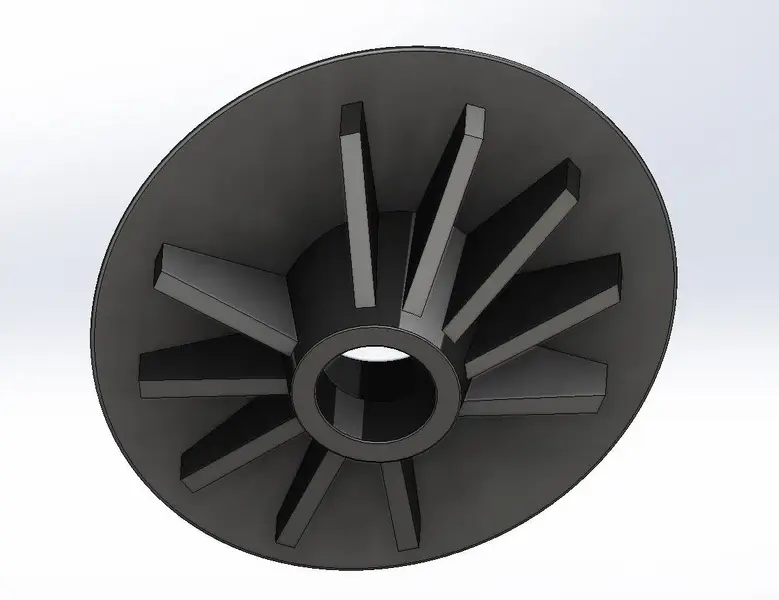

Lastly there is a CNC version. I've only seen a few of these. I had two at one point but sold one along with a stem. I found these quite odd and I've always thought this was DIY job, and not an original/official Syncros cap. Profile is flat compared to the other two and it requires the use of an odd tapered head/countersunk bolt. It's less elegant than the other two and I find it looks clunky in comparision to the other two. Another reason why I think this was a DIY job is that the the round edge of the cap and the portion inserted into the stem isn't angled like the cast metal version, but is squared with the flat top surface. So basically a flat cap design with only the bolt hole bored at the appropriate angle.

Feel free to chime in regarding the origin of the CNC version. Also would love to hear peoples thoughts on the availability of the caps in relationship to production dates of the stems.

So I've seen and have owned three variants of these. The typical and most prone to over-tightening and cracking are the plastic ones. Second and less common are the cast metal ones. I like the fact that they are metal, but I like the look/design of the plastic ones better.

Lastly there is a CNC version. I've only seen a few of these. I had two at one point but sold one along with a stem. I found these quite odd and I've always thought this was DIY job, and not an original/official Syncros cap. Profile is flat compared to the other two and it requires the use of an odd tapered head/countersunk bolt. It's less elegant than the other two and I find it looks clunky in comparision to the other two. Another reason why I think this was a DIY job is that the the round edge of the cap and the portion inserted into the stem isn't angled like the cast metal version, but is squared with the flat top surface. So basically a flat cap design with only the bolt hole bored at the appropriate angle.

Feel free to chime in regarding the origin of the CNC version. Also would love to hear peoples thoughts on the availability of the caps in relationship to production dates of the stems.