This is after trying to bend the tube back into a circle. It clamps but still super tight fit with a 26.8I imagine the seat lug clamp has been distorted by various seatpost extraction attempts, have you tried closing it back up without the seatpost fitted, that may help it grip as would a picture on here if you are unsure. As for seatpost I agree that a 26.6 should fit if a 26.8 doesn't.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I had exactly this on a bv frame last year. Soda'd the post out, but had to re-dress the lug as the previous animal had tried to lever the post out with screwdrivers, bolts, god knows what else!

I would buy the longest post that fits the tube where its not damaged lower down, so 26.6. That way you have all the support you need in the tube.....the top bits just got to stop it moving. Re-dress the top of the lug and very gently file out any internal damage at the top.....else your posts will be scratched to buggery every time you put one in.

Try tinfoiling the inside of the seatpost too.

Grease.

As you frame has a decent length split behind the lug, the lug should close up round the post. Dont go mad with the clamp as it only needs to stop the post moving not crush it to death!

But hey....that's just what would do....

I would buy the longest post that fits the tube where its not damaged lower down, so 26.6. That way you have all the support you need in the tube.....the top bits just got to stop it moving. Re-dress the top of the lug and very gently file out any internal damage at the top.....else your posts will be scratched to buggery every time you put one in.

Try tinfoiling the inside of the seatpost too.

Grease.

As you frame has a decent length split behind the lug, the lug should close up round the post. Dont go mad with the clamp as it only needs to stop the post moving not crush it to death!

But hey....that's just what would do....

focomat 1c

Retro Guru

Looking at your first photo there seems to be a cut/notch ? at about a ' quarter to ' it would be desirable to remove this when you dress

the top/inside of the lug as above .

To remove any corrosion/gunk from the lower portions of the seat tube I would recommend buying a piece of wooden dowel at least 600mm

long x 10mm dia. Cut a slot in the end to take a 25mm fabric backed abrasive strip , wind the abrasive around the dowel and clean out / polish

the seat tube using an electric drill

the top/inside of the lug as above .

To remove any corrosion/gunk from the lower portions of the seat tube I would recommend buying a piece of wooden dowel at least 600mm

long x 10mm dia. Cut a slot in the end to take a 25mm fabric backed abrasive strip , wind the abrasive around the dowel and clean out / polish

the seat tube using an electric drill

Tinfoil it.....coathanger, drill, tinfoil.

https://www.retrobike.co.uk/threads/cleaning-preserving-the-inside-of-a-steel-frame.416121/

https://www.retrobike.co.uk/threads/cleaning-preserving-the-inside-of-a-steel-frame.416121/

great advice! thank you!Looking at your first photo there seems to be a cut/notch ? at about a ' quarter to ' it would be desirable to remove this when you dress

the top/inside of the lug as above .

To remove any corrosion/gunk from the lower portions of the seat tube I would recommend buying a piece of wooden dowel at least 600mm

long x 10mm dia. Cut a slot in the end to take a 25mm fabric backed abrasive strip , wind the abrasive around the dowel and clean out / polish

the seat tube using an electric drill

thank you! im ordering a 300m post and thoroughly cleaning the inside of the tube.I had exactly this on a bv frame last year. Soda'd the post out, but had to re-dress the lug as the previous animal had tried to lever the post out with screwdrivers, bolts, god knows what else!

I would buy the longest post that fits the tube where its not damaged lower down, so 26.6. That way you have all the support you need in the tube.....the top bits just got to stop it moving. Re-dress the top of the lug and very gently file out any internal damage at the top.....else your posts will be scratched to buggery every time you put one in.

Try tinfoiling the inside of the seatpost too.

Grease.

As you frame has a decent length split behind the lug, the lug should close up round the post. Dont go mad with the clamp as it only needs to stop the post moving not crush it to death!

But hey....that's just what would do....

Splatter Paint

Retrobike Rider

- Feedback

- View

I have used a section of threaded bar with cut down Scotchbite pads sandwiched between two nuts. I used this like a plunger to remove oxidation.

The frame has tange mtb tubing. I looked it up and I believe it said 28.6 s.b.t. On tanges catalog. . No clue what the abbreviation is.

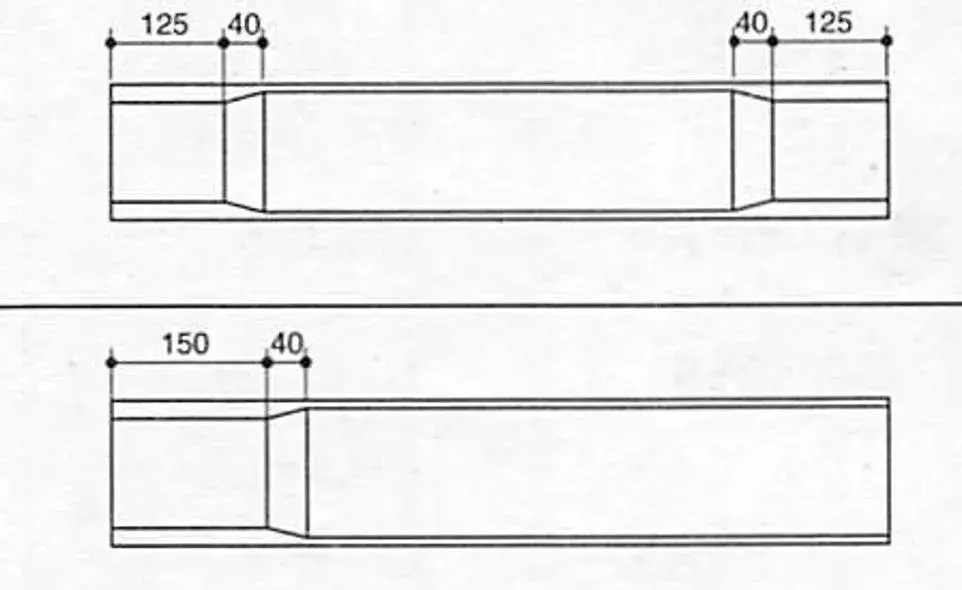

S.B.T. = Single Butted Tube.

28.6 = Seat tube outside diameter in mm, 1-1/8" in old money.

So the seat tube has a thicker wall (butt) down at the bottom bracket end where the stresses are greatest...but no matching butt up at the seat post end. This is how most seat tubes are done, to get the long, consistent bore to support the seat tube.

Top and down tubes are usually double butted to give strength at each end, and save weight in the middle, without the requirement for a sliding fit inside.

Similar threads

- Replies

- 40

- Views

- 2K

- Replies

- 5

- Views

- 479

- Replies

- 1

- Views

- 997

- Replies

- 5

- Views

- 193

- Replies

- 4

- Views

- 826

Latest posts

-

Where's my forest gone? To the Grouse...that's where....

- Latest: highlandsflyer

-

-

-