You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beating metal curves tips ?

- Thread starter Joe*Pro

- Start date

Joe*Pro

Senior Retro Guru

I’ll like the idea of clamping it down rather than hitting it. Yes did gently bend some once before so understand the brittle power impact issue generally.I don't think they look too bad, if this is something you haven't done before they could end up looking worse than they do now, the week spot will be the inverted V of the outer cage so if you try and straighten them out before bending back, they could easily crack at the V. It looks like one of them is already on it's way

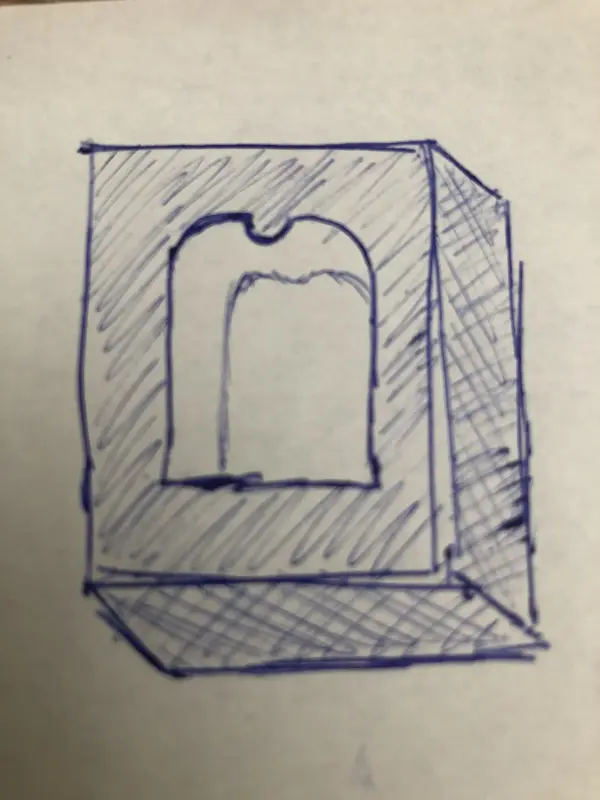

If i was doing it, i would make a hardwood former just slightly undersize the desired shape of the inside of the outer cage (to allow for a bit of spring back) put the former inside the cage and use g-clamps to press the cage to the shape of the former, i appreciate making a former isn't easy for everyone..

Am good at woodwork so can make a buck with cordless jigsaw and tools I have, if I can get nice peice of hardwood. Just need to by some ratchet clamps. (Any excuse)

Yes there are some tiny cracks elsewhere already.

Joe*Pro

Senior Retro Guru

All correct and agree. This is helpful.As eagle eye Betsy spotted there's a little crack forming in that v....anything you now do will make that grow! I'm assuming originally that was more of a rounded shape as well? I'm with Betsy with a former...however it's a fair amount of work ! Plus if you don't get the former really good when you put the cage back on you'll find that the little bolt holes will shift in relation to the body....so it could all look ok in your hand and then you'll have to bend again to get it to line up...you could be setting yourself up for a bit of faff

Maybe if you have a vice and a bit of strap like a ratchet strap you could insert strap through the cage and clamp the strap in vice and give it some pull action whilst cages are still on?

I wouldn't aim for perfect....think it'll start going wrong if that's your aim..just a bit neater

When it comes to refinishing the surface no polish paste will remove the scratches and gouges you have to smooth the surface with filing or sandpaper and go through the grades to 1000 wetndry then polish with a paste!

Pedals really do have a hard life they take the brunt of eveything!

Don’t want perfection just my best attempt at a tidy up, the faff will be worth it I hope.

All will become more clear when they are finished and mounted, (with credit to your support tips) but let’s just say mint NOS versions are $300 and these were $80 because they were collection only from Singapore !!! (I’m London!!!)

the last pair I could find sold worldwide was in 2016 and the buyer has promised to sell them on to me if he ever wants to let them go.

Last edited:

Joe*Pro

Senior Retro Guru

Good idea. I’ll make a full wooden pedal buck and slide these on the outside.To keep the bolts in the correct position, you can use the bolt holes to screw the cage to the former with wood screws before you start pressing the shape

Joe*Pro

Senior Retro Guru

Great example pics. I guess if I use the jigsaw I’ll have both. I’ll start with the inner like you suggest. Maybe use bit of both.

Similar threads

- Replies

- 153

- Views

- 29K

- Replies

- 61

- Views

- 18K

- Replies

- 27

- Views

- 6K

- Replies

- 24

- Views

- 7K