You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Giant Cadex CFM1

- Thread starter YourroyalHEINniss

- Start date

Double-E F

Gold Trader

- Feedback

- View

Wow! Awesome build  !

!

Soundifferent

Specialized Fan

YourroyalHEINniss

Retro Guru

Sounddifferent? ....... So does the text in the brochure  Italian! But luckily the pictures speak for themselves.

Italian! But luckily the pictures speak for themselves.

Soundifferent

Specialized Fan

Yes, I’m ItalianSounddifferent? ....... So does the text in the brochureItalian! But luckily the pictures speak for themselves.

Soundifferent

Specialized Fan

H

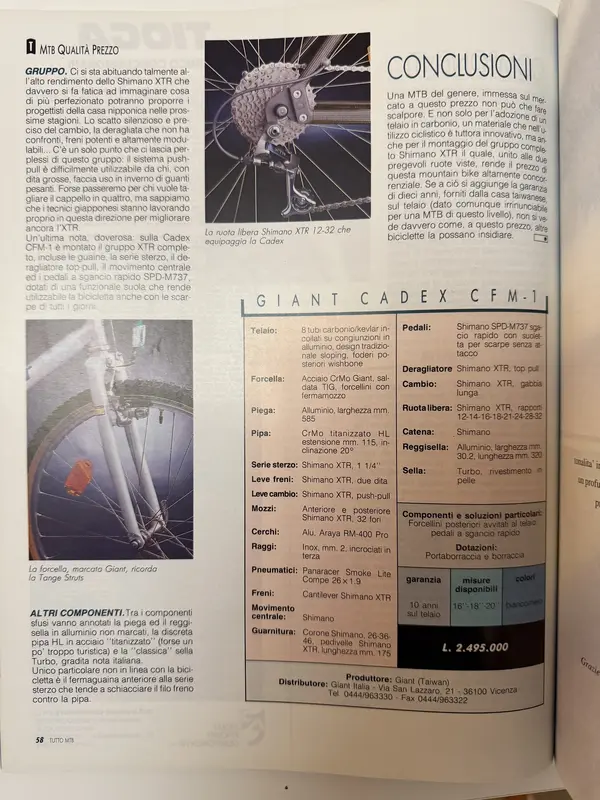

Giant Cadex CFM-1

Tachia is one of the most industrialised countries in Taiwan. There are significant industries that employ thousands of people.

1400 of these (1520 last year) work in the Giant plants, the only company Of which, in Tachia, indicator arrows have been prepared. Trucks and container carriers continuously depart from here to Taipei's ports and airports to adequately supply the dozens of Giant branches around the world. Branches that have, we have been explained, decision-making power in the choice of models, sizes, colours and sales strategies. It is therefore easy to observe different projects on the same frame for nations also close to each other, and in total

It must be considered that the parent company of Taiwan comes to produce almost a thousand different models in the year (!). Among all these, the most pre-stigious, also marketed in Italy, is called Cadex CFM-1 and is mounted with the complete Shimano XTR group.

This model has been discussed, and perhaps much remains to be said about it. Suffice it to mention the fact that many European companies have appealed to the Supreme Court of the EEC to report Giant (together with 26 other Taiwanese companies) for dumping (sale below cost abroad). And this is being tested today and, in all probability, the model that caused most of those ire. Ire that will be answered in late September when the EEC Commission will meet in The Hague to deliberate.

The reason for such a "riot" is explained by a few elementary accounts: the XTR group, alone, has a price to the public in Italy around two million; rims, accessories, various components and assembly can be grouped in a single item for a few hundred thousand lire. And the frame? It's out of this account, and it's carbon! And, most likely, it is precisely this bicycle that will contribute to bringing down several "myths"; first of all that of the high costs of composite fibres, the most "chattered" of which among cyclists is carbon fibre.

Frame

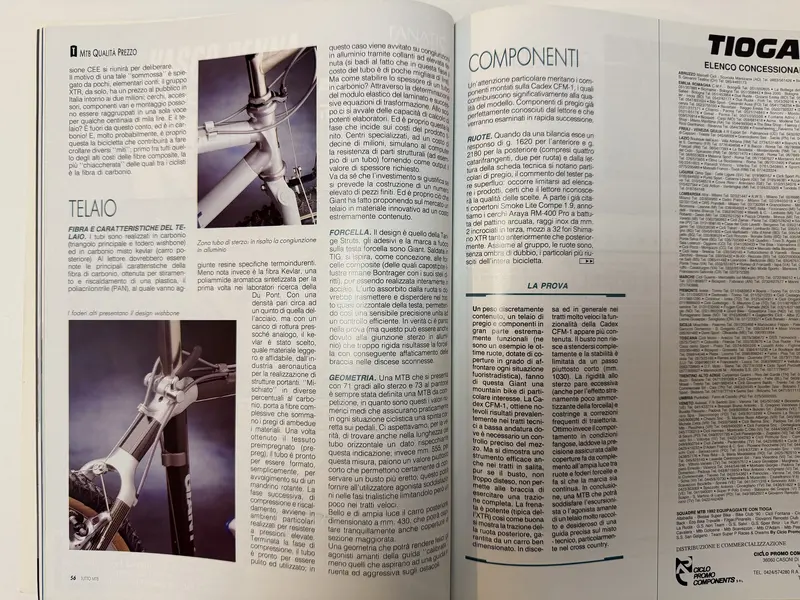

FIBRE AND FRAME CHARACTERISTICS. The tubes are made of carbon (main triangle and wishbone sheath is made of Kevlar mixed carbon (rear waggon). The reader should be aware of the main characteristics of carbon fibre, obtained by stretching and heating a plastic, the Polyacrylonitrile (PAN), to which specific thermosetting resins must be added.

Less well known instead is Kevlar fibre, an aromatic polyamide synthesised for the first time in research laboratories of the Dupont. With a density equal to about a fifth of that of steel, but with a Breaking load almost analogue, Kevlar, It was chosen, as a light and reliable material, by the aeronautical industry for the realisation of load-bearing structures. "Miscled" In different percentages of carbon, it leads to overall fibres that add up the merits of both materials. Once the pre-impregnated fabric (pre-preg) has been obtained, the tube is ready to be formed, simply, to Winding on a rotating chuck. The next phase, of compression and heating takes place in particular environments Made to withstand high pressures. Once the compression phase is over, the tube It is ready to be cleaned and used; in This case is screwed on aluminum conjunctions by means of high lift castings (note the fact that at this stage the cost of the tube is a few thousand).

But how to establish the thickness of a carbon tube? Through the determination of the elastic modulus of the laminate and success of the equations of transformation. In the same way, it makes use of the computing capabilities of powerful processors. And this is precisely the phase that affects the costs of the finished product. Specialised centres, at a cost of tens of millions, simulate on the computer

The resistance of structural parts (for example of a pipe) providing the required thickness value as output.

It goes without saying that the investment is justified if the construction of a large number of finished parts is expected. And that's exactly what Giant did by offering an innovative material frame on the market at an extremely low cost.

FORK. The design is that of the Tange Struts, the stickers and the brand in focus on the fork head are Giant. TIG Welded, is inspired, as a conception, by composite forks (of which the progenitor the Lustre remains Bontrager with its stems of ritti), despite being made entirely of steel. The impact absorbed by the wheel should be transmitted and dispersed in the almost horizontal section of the head, thus allowing a sensitive precision combined with efficient control. In truth, it seemed to us in the test (but this may also be due to the aluminum steering joint) that the fork was too rigid with consequent fatigue of the Arms in the uncounted descents.

GEOMETRY. An MTB that comes with 71 degrees on the steering wheel and 73 on the column It has always been defined as an MTB from competition, as these are the average numerical values that ensure a correct push on the pedals in practically every cycling situation. We expected, for the truth, to find also in the length of the horizontal tube a data reflecting this indication; instead mm. 555, for this measure, seem a rather short value that certainly allows to maintain a more erect torso; this will be able to provide the agonist user with satisfaction in the trial phases limiting for small people in the fast stretches.

Beautiful and wide light the rear carriage, sized at 430 mm, which can easily accommodate covers of Increased section.

A geometry that can make agonists who love "calibrated" driving happy, less those who aspire to impetuous and aggressive driving on obstacles.

COMPONENTS

Special attention is paid to the components mounted on the Cadex CFM-1, which contribute significantly to the quality of the model. Valuable components already perfectly known to the reader and that will be scrutinised in rapid succession.

WHEELS. When a response of g. 1620 for the front and g. comes out of a balanced 2180 for the rear (including four reflectors, two per wheel) and from reading the technical sheet you can see valuable details, the tester's comment seems superfluous: it is necessary to limit ourselves to listing the products, certain that the reader will recognise the quality of the choices. Apart from the aforementioned Smoke Lite Compete 1.9 tires, we note the Araya RM-400 Pro rims with arched skate stop, stainless steel spokes of mm. 2 crossed in third, 32-hole Shima-no XTR hubs both front and rear. Together with the group, the wheels are, without a shadow of a doubt, the most successful details of the entire bicycle.

GROUP. You are getting so used to the high performance of the Shimano XTR that it is really hard to imagine what more perfected the designers of the Japanese house will be able to propose in the coming seasons. The silent and precise click of the gearbox, the derailleur that has no comparison, powerful and highly modular brakes... There is only one point that leaves us perplexed about this group: the push-pull system is difficult to use by those who, with big fingers, use heavy gloves in winter. Maybe we will pass for those who want to cut the hat in four, but we know that the Japanese technicians are working precisely in this direction to improve XTR even more.

One last note:

CFM-1 is fitted with the complete XTR group, including sheaths, headset, top-pull derailleur, bottom bracket and SPD-M737 quick release pedals, Equipped with a functional sole that makes the bike useable even with everyday shoes.

OTHER COMPONENTS. Among the bulk components, the unmarked aluminum fold and seatpost, the discreet HL pipe in "titanised" steel (perhaps a little too touristy) and the "classic" Turbo saddle

The only detail not in line with the bicycle is the front sheath stop to the steering gear that tends to crush the brake wire Against the pipe.

CONCLUSIONS

An MTB like that, put on the market at this price, is not to be a stir. And not only for the adoption of a carbon frame, a material that is still innovative in cycling use, but also for the assembly of the complete Shimano XTR group which, combined with the two valuable wheels seen, makes the price of this mountain bike highly competitive. If you add to this the ten-year warranty, provided by the Taiwanese company on the frame given however indispensable for an MTB of this level, you don't really see how, at this price, other bicycles can undermine it.

THE TEST

A fairly low weight, a valuable frame and largely extremely functional components

An example is the excellent wheels, equipped with covers capable of facing any off-road situation), make this Giant a mountain bike of particular interest. The Ca-dex CFM-1, obtains remarkable results mainly in low-get technical sections where precise control of the vehicle is necessary. But it proves to be an effective tool even in the uphill sections,

Even if the torso, not too stretched, does not allow the arms to exert complete traction. The braking is powerful (typical of the I'XTR) as well as the traction of the rear wheel, guaranteed by a well-sized waggon. Downhill and in general in very fast sections the functionality of the Cadex

CFM-1 appears more contained. The torso cannot lie down completely and the stability is limited by a rather short step ( mm. 1030) The rigidity at the steering seems excessive

(Also for the strangely little damping effect of the fork) and forces frequent trajectory corrections.

On the other hand, the behaviour in tango conditions is excellent, where the precision ensured by the Covers complement the wide light between wheels and fork linings and ensures that the march is continuous. In conclusion, an MTB that will satisfy the hiker or the racer who loves a very well-raised frame and eager for a precise guide on the technical mix, particularly in cross country.

Here’s a quick translation:Sounddifferent? ....... So does the text in the brochureItalian! But luckily the pictures speak for

Giant Cadex CFM-1

Tachia is one of the most industrialised countries in Taiwan. There are significant industries that employ thousands of people.

1400 of these (1520 last year) work in the Giant plants, the only company Of which, in Tachia, indicator arrows have been prepared. Trucks and container carriers continuously depart from here to Taipei's ports and airports to adequately supply the dozens of Giant branches around the world. Branches that have, we have been explained, decision-making power in the choice of models, sizes, colours and sales strategies. It is therefore easy to observe different projects on the same frame for nations also close to each other, and in total

It must be considered that the parent company of Taiwan comes to produce almost a thousand different models in the year (!). Among all these, the most pre-stigious, also marketed in Italy, is called Cadex CFM-1 and is mounted with the complete Shimano XTR group.

This model has been discussed, and perhaps much remains to be said about it. Suffice it to mention the fact that many European companies have appealed to the Supreme Court of the EEC to report Giant (together with 26 other Taiwanese companies) for dumping (sale below cost abroad). And this is being tested today and, in all probability, the model that caused most of those ire. Ire that will be answered in late September when the EEC Commission will meet in The Hague to deliberate.

The reason for such a "riot" is explained by a few elementary accounts: the XTR group, alone, has a price to the public in Italy around two million; rims, accessories, various components and assembly can be grouped in a single item for a few hundred thousand lire. And the frame? It's out of this account, and it's carbon! And, most likely, it is precisely this bicycle that will contribute to bringing down several "myths"; first of all that of the high costs of composite fibres, the most "chattered" of which among cyclists is carbon fibre.

Frame

FIBRE AND FRAME CHARACTERISTICS. The tubes are made of carbon (main triangle and wishbone sheath is made of Kevlar mixed carbon (rear waggon). The reader should be aware of the main characteristics of carbon fibre, obtained by stretching and heating a plastic, the Polyacrylonitrile (PAN), to which specific thermosetting resins must be added.

Less well known instead is Kevlar fibre, an aromatic polyamide synthesised for the first time in research laboratories of the Dupont. With a density equal to about a fifth of that of steel, but with a Breaking load almost analogue, Kevlar, It was chosen, as a light and reliable material, by the aeronautical industry for the realisation of load-bearing structures. "Miscled" In different percentages of carbon, it leads to overall fibres that add up the merits of both materials. Once the pre-impregnated fabric (pre-preg) has been obtained, the tube is ready to be formed, simply, to Winding on a rotating chuck. The next phase, of compression and heating takes place in particular environments Made to withstand high pressures. Once the compression phase is over, the tube It is ready to be cleaned and used; in This case is screwed on aluminum conjunctions by means of high lift castings (note the fact that at this stage the cost of the tube is a few thousand).

But how to establish the thickness of a carbon tube? Through the determination of the elastic modulus of the laminate and success of the equations of transformation. In the same way, it makes use of the computing capabilities of powerful processors. And this is precisely the phase that affects the costs of the finished product. Specialised centres, at a cost of tens of millions, simulate on the computer

The resistance of structural parts (for example of a pipe) providing the required thickness value as output.

It goes without saying that the investment is justified if the construction of a large number of finished parts is expected. And that's exactly what Giant did by offering an innovative material frame on the market at an extremely low cost.

FORK. The design is that of the Tange Struts, the stickers and the brand in focus on the fork head are Giant. TIG Welded, is inspired, as a conception, by composite forks (of which the progenitor the Lustre remains Bontrager with its stems of ritti), despite being made entirely of steel. The impact absorbed by the wheel should be transmitted and dispersed in the almost horizontal section of the head, thus allowing a sensitive precision combined with efficient control. In truth, it seemed to us in the test (but this may also be due to the aluminum steering joint) that the fork was too rigid with consequent fatigue of the Arms in the uncounted descents.

GEOMETRY. An MTB that comes with 71 degrees on the steering wheel and 73 on the column It has always been defined as an MTB from competition, as these are the average numerical values that ensure a correct push on the pedals in practically every cycling situation. We expected, for the truth, to find also in the length of the horizontal tube a data reflecting this indication; instead mm. 555, for this measure, seem a rather short value that certainly allows to maintain a more erect torso; this will be able to provide the agonist user with satisfaction in the trial phases limiting for small people in the fast stretches.

Beautiful and wide light the rear carriage, sized at 430 mm, which can easily accommodate covers of Increased section.

A geometry that can make agonists who love "calibrated" driving happy, less those who aspire to impetuous and aggressive driving on obstacles.

COMPONENTS

Special attention is paid to the components mounted on the Cadex CFM-1, which contribute significantly to the quality of the model. Valuable components already perfectly known to the reader and that will be scrutinised in rapid succession.

WHEELS. When a response of g. 1620 for the front and g. comes out of a balanced 2180 for the rear (including four reflectors, two per wheel) and from reading the technical sheet you can see valuable details, the tester's comment seems superfluous: it is necessary to limit ourselves to listing the products, certain that the reader will recognise the quality of the choices. Apart from the aforementioned Smoke Lite Compete 1.9 tires, we note the Araya RM-400 Pro rims with arched skate stop, stainless steel spokes of mm. 2 crossed in third, 32-hole Shima-no XTR hubs both front and rear. Together with the group, the wheels are, without a shadow of a doubt, the most successful details of the entire bicycle.

GROUP. You are getting so used to the high performance of the Shimano XTR that it is really hard to imagine what more perfected the designers of the Japanese house will be able to propose in the coming seasons. The silent and precise click of the gearbox, the derailleur that has no comparison, powerful and highly modular brakes... There is only one point that leaves us perplexed about this group: the push-pull system is difficult to use by those who, with big fingers, use heavy gloves in winter. Maybe we will pass for those who want to cut the hat in four, but we know that the Japanese technicians are working precisely in this direction to improve XTR even more.

One last note:

CFM-1 is fitted with the complete XTR group, including sheaths, headset, top-pull derailleur, bottom bracket and SPD-M737 quick release pedals, Equipped with a functional sole that makes the bike useable even with everyday shoes.

OTHER COMPONENTS. Among the bulk components, the unmarked aluminum fold and seatpost, the discreet HL pipe in "titanised" steel (perhaps a little too touristy) and the "classic" Turbo saddle

The only detail not in line with the bicycle is the front sheath stop to the steering gear that tends to crush the brake wire Against the pipe.

CONCLUSIONS

An MTB like that, put on the market at this price, is not to be a stir. And not only for the adoption of a carbon frame, a material that is still innovative in cycling use, but also for the assembly of the complete Shimano XTR group which, combined with the two valuable wheels seen, makes the price of this mountain bike highly competitive. If you add to this the ten-year warranty, provided by the Taiwanese company on the frame given however indispensable for an MTB of this level, you don't really see how, at this price, other bicycles can undermine it.

THE TEST

A fairly low weight, a valuable frame and largely extremely functional components

An example is the excellent wheels, equipped with covers capable of facing any off-road situation), make this Giant a mountain bike of particular interest. The Ca-dex CFM-1, obtains remarkable results mainly in low-get technical sections where precise control of the vehicle is necessary. But it proves to be an effective tool even in the uphill sections,

Even if the torso, not too stretched, does not allow the arms to exert complete traction. The braking is powerful (typical of the I'XTR) as well as the traction of the rear wheel, guaranteed by a well-sized waggon. Downhill and in general in very fast sections the functionality of the Cadex

CFM-1 appears more contained. The torso cannot lie down completely and the stability is limited by a rather short step ( mm. 1030) The rigidity at the steering seems excessive

(Also for the strangely little damping effect of the fork) and forces frequent trajectory corrections.

On the other hand, the behaviour in tango conditions is excellent, where the precision ensured by the Covers complement the wide light between wheels and fork linings and ensures that the march is continuous. In conclusion, an MTB that will satisfy the hiker or the racer who loves a very well-raised frame and eager for a precise guide on the technical mix, particularly in cross country.

YourroyalHEINniss

Retro Guru

H

Here’s a quick translation:

Giant Cadex CFM-1

Tachia is one of the most industrialised countries in Taiwan. There are significant industries that employ thousands of people.

1400 of these (1520 last year) work in the Giant plants, the only company Of which, in Tachia, indicator arrows have been prepared. Trucks and container carriers continuously depart from here to Taipei's ports and airports to adequately supply the dozens of Giant branches around the world. Branches that have, we have been explained, decision-making power in the choice of models, sizes, colours and sales strategies. It is therefore easy to observe different projects on the same frame for nations also close to each other, and in total

It must be considered that the parent company of Taiwan comes to produce almost a thousand different models in the year (!). Among all these, the most pre-stigious, also marketed in Italy, is called Cadex CFM-1 and is mounted with the complete Shimano XTR group.

This model has been discussed, and perhaps much remains to be said about it. Suffice it to mention the fact that many European companies have appealed to the Supreme Court of the EEC to report Giant (together with 26 other Taiwanese companies) for dumping (sale below cost abroad). And this is being tested today and, in all probability, the model that caused most of those ire. Ire that will be answered in late September when the EEC Commission will meet in The Hague to deliberate.

The reason for such a "riot" is explained by a few elementary accounts: the XTR group, alone, has a price to the public in Italy around two million; rims, accessories, various components and assembly can be grouped in a single item for a few hundred thousand lire. And the frame? It's out of this account, and it's carbon! And, most likely, it is precisely this bicycle that will contribute to bringing down several "myths"; first of all that of the high costs of composite fibres, the most "chattered" of which among cyclists is carbon fibre.

Frame

FIBRE AND FRAME CHARACTERISTICS. The tubes are made of carbon (main triangle and wishbone sheath is made of Kevlar mixed carbon (rear waggon). The reader should be aware of the main characteristics of carbon fibre, obtained by stretching and heating a plastic, the Polyacrylonitrile (PAN), to which specific thermosetting resins must be added.

Less well known instead is Kevlar fibre, an aromatic polyamide synthesised for the first time in research laboratories of the Dupont. With a density equal to about a fifth of that of steel, but with a Breaking load almost analogue, Kevlar, It was chosen, as a light and reliable material, by the aeronautical industry for the realisation of load-bearing structures. "Miscled" In different percentages of carbon, it leads to overall fibres that add up the merits of both materials. Once the pre-impregnated fabric (pre-preg) has been obtained, the tube is ready to be formed, simply, to Winding on a rotating chuck. The next phase, of compression and heating takes place in particular environments Made to withstand high pressures. Once the compression phase is over, the tube It is ready to be cleaned and used; in This case is screwed on aluminum conjunctions by means of high lift castings (note the fact that at this stage the cost of the tube is a few thousand).

But how to establish the thickness of a carbon tube? Through the determination of the elastic modulus of the laminate and success of the equations of transformation. In the same way, it makes use of the computing capabilities of powerful processors. And this is precisely the phase that affects the costs of the finished product. Specialised centres, at a cost of tens of millions, simulate on the computer

The resistance of structural parts (for example of a pipe) providing the required thickness value as output.

It goes without saying that the investment is justified if the construction of a large number of finished parts is expected. And that's exactly what Giant did by offering an innovative material frame on the market at an extremely low cost.

FORK. The design is that of the Tange Struts, the stickers and the brand in focus on the fork head are Giant. TIG Welded, is inspired, as a conception, by composite forks (of which the progenitor the Lustre remains Bontrager with its stems of ritti), despite being made entirely of steel. The impact absorbed by the wheel should be transmitted and dispersed in the almost horizontal section of the head, thus allowing a sensitive precision combined with efficient control. In truth, it seemed to us in the test (but this may also be due to the aluminum steering joint) that the fork was too rigid with consequent fatigue of the Arms in the uncounted descents.

GEOMETRY. An MTB that comes with 71 degrees on the steering wheel and 73 on the column It has always been defined as an MTB from competition, as these are the average numerical values that ensure a correct push on the pedals in practically every cycling situation. We expected, for the truth, to find also in the length of the horizontal tube a data reflecting this indication; instead mm. 555, for this measure, seem a rather short value that certainly allows to maintain a more erect torso; this will be able to provide the agonist user with satisfaction in the trial phases limiting for small people in the fast stretches.

Beautiful and wide light the rear carriage, sized at 430 mm, which can easily accommodate covers of Increased section.

A geometry that can make agonists who love "calibrated" driving happy, less those who aspire to impetuous and aggressive driving on obstacles.

COMPONENTS

Special attention is paid to the components mounted on the Cadex CFM-1, which contribute significantly to the quality of the model. Valuable components already perfectly known to the reader and that will be scrutinised in rapid succession.

WHEELS. When a response of g. 1620 for the front and g. comes out of a balanced 2180 for the rear (including four reflectors, two per wheel) and from reading the technical sheet you can see valuable details, the tester's comment seems superfluous: it is necessary to limit ourselves to listing the products, certain that the reader will recognise the quality of the choices. Apart from the aforementioned Smoke Lite Compete 1.9 tires, we note the Araya RM-400 Pro rims with arched skate stop, stainless steel spokes of mm. 2 crossed in third, 32-hole Shima-no XTR hubs both front and rear. Together with the group, the wheels are, without a shadow of a doubt, the most successful details of the entire bicycle.

GROUP. You are getting so used to the high performance of the Shimano XTR that it is really hard to imagine what more perfected the designers of the Japanese house will be able to propose in the coming seasons. The silent and precise click of the gearbox, the derailleur that has no comparison, powerful and highly modular brakes... There is only one point that leaves us perplexed about this group: the push-pull system is difficult to use by those who, with big fingers, use heavy gloves in winter. Maybe we will pass for those who want to cut the hat in four, but we know that the Japanese technicians are working precisely in this direction to improve XTR even more.

One last note:

CFM-1 is fitted with the complete XTR group, including sheaths, headset, top-pull derailleur, bottom bracket and SPD-M737 quick release pedals, Equipped with a functional sole that makes the bike useable even with everyday shoes.

OTHER COMPONENTS. Among the bulk components, the unmarked aluminum fold and seatpost, the discreet HL pipe in "titanised" steel (perhaps a little too touristy) and the "classic" Turbo saddle

The only detail not in line with the bicycle is the front sheath stop to the steering gear that tends to crush the brake wire Against the pipe.

CONCLUSIONS

An MTB like that, put on the market at this price, is not to be a stir. And not only for the adoption of a carbon frame, a material that is still innovative in cycling use, but also for the assembly of the complete Shimano XTR group which, combined with the two valuable wheels seen, makes the price of this mountain bike highly competitive. If you add to this the ten-year warranty, provided by the Taiwanese company on the frame given however indispensable for an MTB of this level, you don't really see how, at this price, other bicycles can undermine it.

THE TEST

A fairly low weight, a valuable frame and largely extremely functional components

An example is the excellent wheels, equipped with covers capable of facing any off-road situation), make this Giant a mountain bike of particular interest. The Ca-dex CFM-1, obtains remarkable results mainly in low-get technical sections where precise control of the vehicle is necessary. But it proves to be an effective tool even in the uphill sections,

Even if the torso, not too stretched, does not allow the arms to exert complete traction. The braking is powerful (typical of the I'XTR) as well as the traction of the rear wheel, guaranteed by a well-sized waggon. Downhill and in general in very fast sections the functionality of the Cadex

CFM-1 appears more contained. The torso cannot lie down completely and the stability is limited by a rather short step ( mm. 1030) The rigidity at the steering seems excessive

(Also for the strangely little damping effect of the fork) and forces frequent trajectory corrections.

On the other hand, the behaviour in tango conditions is excellent, where the precision ensured by the Covers complement the wide light between wheels and fork linings and ensures that the march is continuous. In conclusion, an MTB that will satisfy the hiker or the racer who loves a very well-raised frame and eager for a precise guide on the technical mix, particularly in cross country.

Wow, now it all makes sense.

Thanks, good story.

All this knowledge adds up to the sentimental value of the bike.

Grz

Similar threads

- Replies

- 9

- Views

- 882

- Replies

- 1

- Views

- 991