You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cleland Range Rider (RR-001 English Cycles) Highpath. 1982

- Thread starter REtrouble

- Start date

REtrouble

Cleland Fan

Just out of interest I roughly measured the chainstays on two 26" bikes on hand right now, between the crank centre & rear wheel centre of a 93 Dawes Edge 435mm, 91 Bear Valley 425mm & the Cleland at 420mm, so the Cleland has shorter stays despite it's (at present) larger 700c rims.

I've been riding the Cleland solely for over 4 months now, will be swapping back to the Dawes that I use for touring soon, then I'll post up some observations about what the Cleland is like to ride, I'm curious to see how the Dawes feels after the Cleland.

I've been riding the Cleland solely for over 4 months now, will be swapping back to the Dawes that I use for touring soon, then I'll post up some observations about what the Cleland is like to ride, I'm curious to see how the Dawes feels after the Cleland.

- Feedback

- View

Most mountain bikers have never heard of Cleland and of the small minority of riders that have, only a tiny minority will have ever ridden one.REtrouble":1cd9kzbj said:I've been riding the Cleland solely for over 4 months now, will be swapping back to the Dawes that I use for touring soon, then I'll post up some observations about what the Cleland is like to ride, I'm curious to see how the Dawes feels after the Cleland.

So you are in a privileged situation of being able to compare and contrast two completely different concepts of what an off-road bicycle should be and do. If more of the early uptake mountain bikers were able to compare the ride of the a Cleland with a US style 'Mountain Bike' as I did, then the history of mountain bike design may have been different.

One major difference between the early 'Mountain Bikes' and the Clelands was the tyre technology they used. The 'Mountain Bikes' started with extremely heavy 26" Uni-Royal Knobby 'Klunker' tyres and then onto skin-wall tyres where you needed a reasonably high tyre pressure to stop the skin-walls from self destructing. The Cleland Hakkapeliitta tyres were not only larger in diameter but had tough yet flexible sidewalls, and most importantly inner-tubes that were as fat as the tyres. This meant none of the PSI was wasted on expanding the tube before it touched and supported the sidewall, allowing for much lower running pressures of the order you get with tubeless. The Clelands used modern style narrow rims whilst the trend for the early 'Mountain Bikes' was for fat rims.

The overall effect of the tyre technology of the Clelands was to make an already comfy bike even more comfortable to ride, whilst the larger contact patch meant better grip. Reduced tyre pressures also lowered the rolling resistance on soft or bumpy terrain however on smooth surfaces the rolling resistance was noticeably higher and this was irrespective of how much extra air you added. The best modern tyres do not suffer from this, increased rolling-resistance when running low pressures on smooth surfaces, affliction. Though the side-walls do need to be reinforced in order to prevent them from splitting under load.

REtrouble

Cleland Fan

The brakes are now working fine but I did rather fancy making a "sliding cam" back plate, so seeing as I can't leave anything alone I picked up another front brake back plate & set to work today.

I'm not convinced it'll make a huge difference but there's one way to find out!

The pressed in steel pivot bush removed & the hole elongated so it will float.

The pivot welded to a plate that locates on a 5mm bolt, it can slide both ways in the slotted hole.

Paint on it now so can't get it together for a day or so. I saw a similar mod somewhere else that I can't find right now, I'll post a link when I find it.

I'm not convinced it'll make a huge difference but there's one way to find out!

The pressed in steel pivot bush removed & the hole elongated so it will float.

The pivot welded to a plate that locates on a 5mm bolt, it can slide both ways in the slotted hole.

Paint on it now so can't get it together for a day or so. I saw a similar mod somewhere else that I can't find right now, I'll post a link when I find it.

REtrouble

Cleland Fan

Found the thread that contains a lot of the theory of swing & sliding cam cycle drum brakes if anyone's interested, with input from David Wrath -Sharman.

https://forum.cyclinguk.org/viewtopic.p ... 3&start=15

Mod similar to what I've done near the bottom of page two.

https://forum.cyclinguk.org/viewtopic.p ... 3&start=15

Mod similar to what I've done near the bottom of page two.

- Feedback

- View

Those seat stays could be just about anything available at the time.

REtrouble

Cleland Fan

I said on page one.legrandefromage":1azya3vi said:Those seat stays could be just about anything available at the time.

"On the top of the seatstays "slash cut" very faintly under the paint can be seen "Raleigh".

So Drcarlos's suggestions are based on that.

.

- Feedback

- View

Re:

Looks like a well executed modification

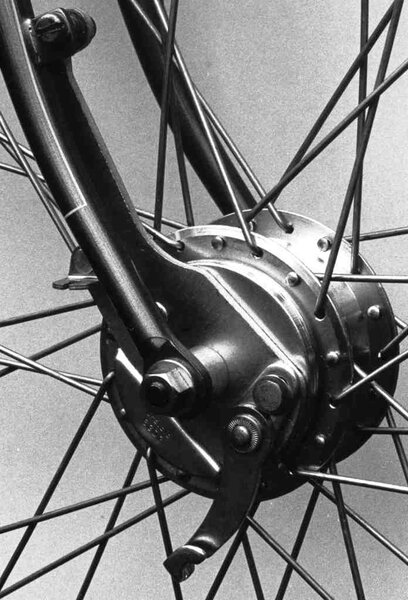

The floating cam mechanism is intended to make a mechanical hub brake function like the hydraulic one shown below:

With a hydraulic drum brake the force of the fluid is split two ways i.e. 50% right and 50% left regardless of any uneven wear of the two brake shoes. With a floating cam, any uneven loading of the cam should cause it to centre itself between the shoes so that the braking forces are evenly split.

Despite their claim to be the "best", it is possible for a standard Sturmey Archer Elite brake to put all the braking force into only one shoe, the other being effectively redundant. Also, since the leading and trailing shoes wear at different rates this problem will become more evident over time.

I don't think that the Marin pioneers ever used floating cam brakes on their Clunkers. If they had they may have stuck with drum brakes instead of shifting over to cantilevers.

The 'Leleu' floating cam brakes used on the Clelands also had a minimum distance of over 80mm of heat radiating aluminium between the braking surface and the nearest wheel bearing, so no need to 'repack' after a long downhill.

Even with a correctly centering floating cam it will still take time for the shoes to properly bed in and so achieve their maximum braking force. I would also remove a short section of the sealing ring at the bottom of the brake plate, so as to allow any brake dust or water to escape.

Looks like a well executed modification

The floating cam mechanism is intended to make a mechanical hub brake function like the hydraulic one shown below:

With a hydraulic drum brake the force of the fluid is split two ways i.e. 50% right and 50% left regardless of any uneven wear of the two brake shoes. With a floating cam, any uneven loading of the cam should cause it to centre itself between the shoes so that the braking forces are evenly split.

Despite their claim to be the "best", it is possible for a standard Sturmey Archer Elite brake to put all the braking force into only one shoe, the other being effectively redundant. Also, since the leading and trailing shoes wear at different rates this problem will become more evident over time.

I don't think that the Marin pioneers ever used floating cam brakes on their Clunkers. If they had they may have stuck with drum brakes instead of shifting over to cantilevers.

The 'Leleu' floating cam brakes used on the Clelands also had a minimum distance of over 80mm of heat radiating aluminium between the braking surface and the nearest wheel bearing, so no need to 'repack' after a long downhill.

Even with a correctly centering floating cam it will still take time for the shoes to properly bed in and so achieve their maximum braking force. I would also remove a short section of the sealing ring at the bottom of the brake plate, so as to allow any brake dust or water to escape.

Attachments

Similar threads

- Replies

- 4

- Views

- 568

- Replies

- 12

- Views

- 1K

Latest posts

-

-

For Sale 1988 Ridgeback 603 22” Frame. Exceptional condition for age.

- Latest: Braze O'Mar

-

-