Betsy

Old School Grand Master

I wanted to hear what it sounded like with my small Rel (10"sq) sub decoupled but the smallest isolation pad i could find was 380mm sq and 30+ quid so i thought i'd just make one instead.

Split a piece of oak

Made a former with some pads on the same centers as the subwoofers legs and gave it a coat of mould release solution

After 25yrs a faded Steve Pete is still hanging around my workshop

Bored some holes

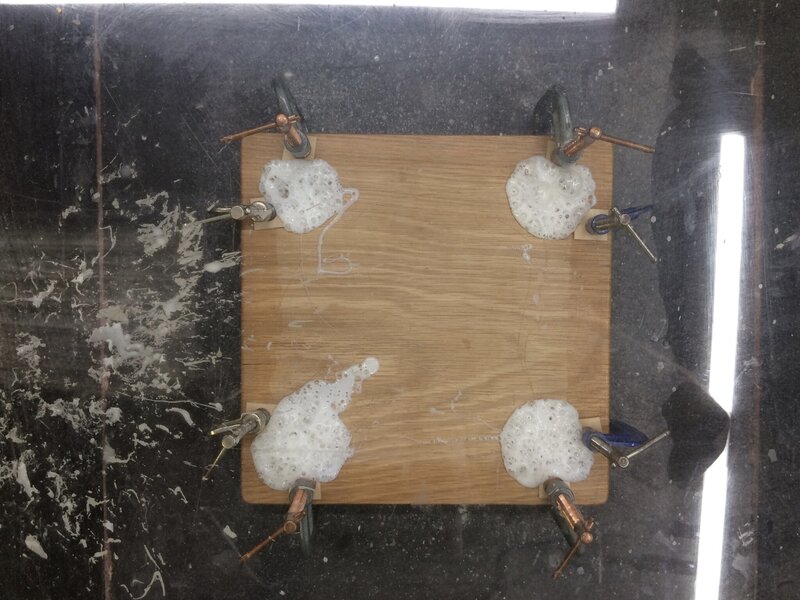

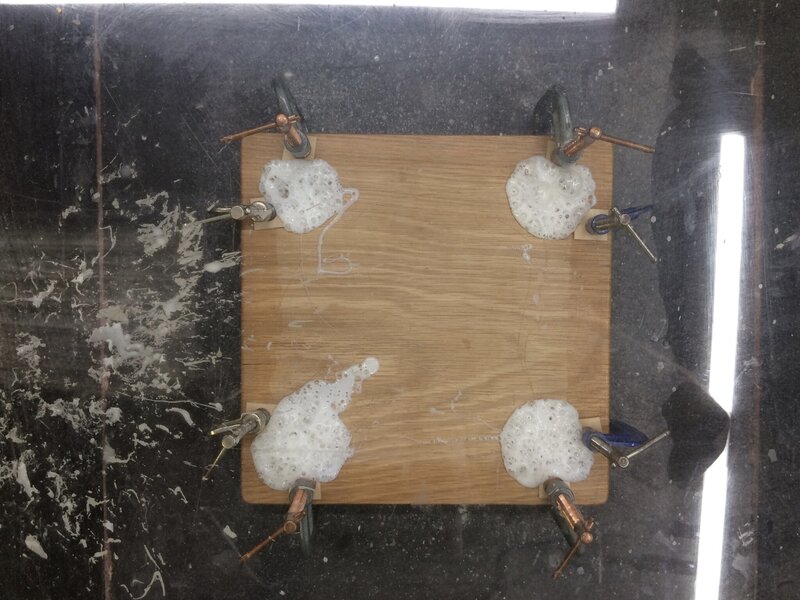

Mixed some silicone and ran it through the vacuum chamber to remove the air

Poured it through the back of the oak which i had clamped to the former and ran it through a secondry vacuum to remove the air from the mould

Split the oak from the former leaving squidgy vibration absorbing rubber recesses

Covered the holes on the back (which i cast through +vents) with class o acoustic foam

...and there you go

Decoupled

Split a piece of oak

Made a former with some pads on the same centers as the subwoofers legs and gave it a coat of mould release solution

After 25yrs a faded Steve Pete is still hanging around my workshop

Bored some holes

Mixed some silicone and ran it through the vacuum chamber to remove the air

Poured it through the back of the oak which i had clamped to the former and ran it through a secondry vacuum to remove the air from the mould

Split the oak from the former leaving squidgy vibration absorbing rubber recesses

Covered the holes on the back (which i cast through +vents) with class o acoustic foam

...and there you go

Decoupled