Thias

Klein Fan

I'm thinking on what part to make or modify next. I've been playing with one if these inverse M951 DRs. And I would like to take one apart and make two new parallelogram parts to convert it no - well - how it should have been.

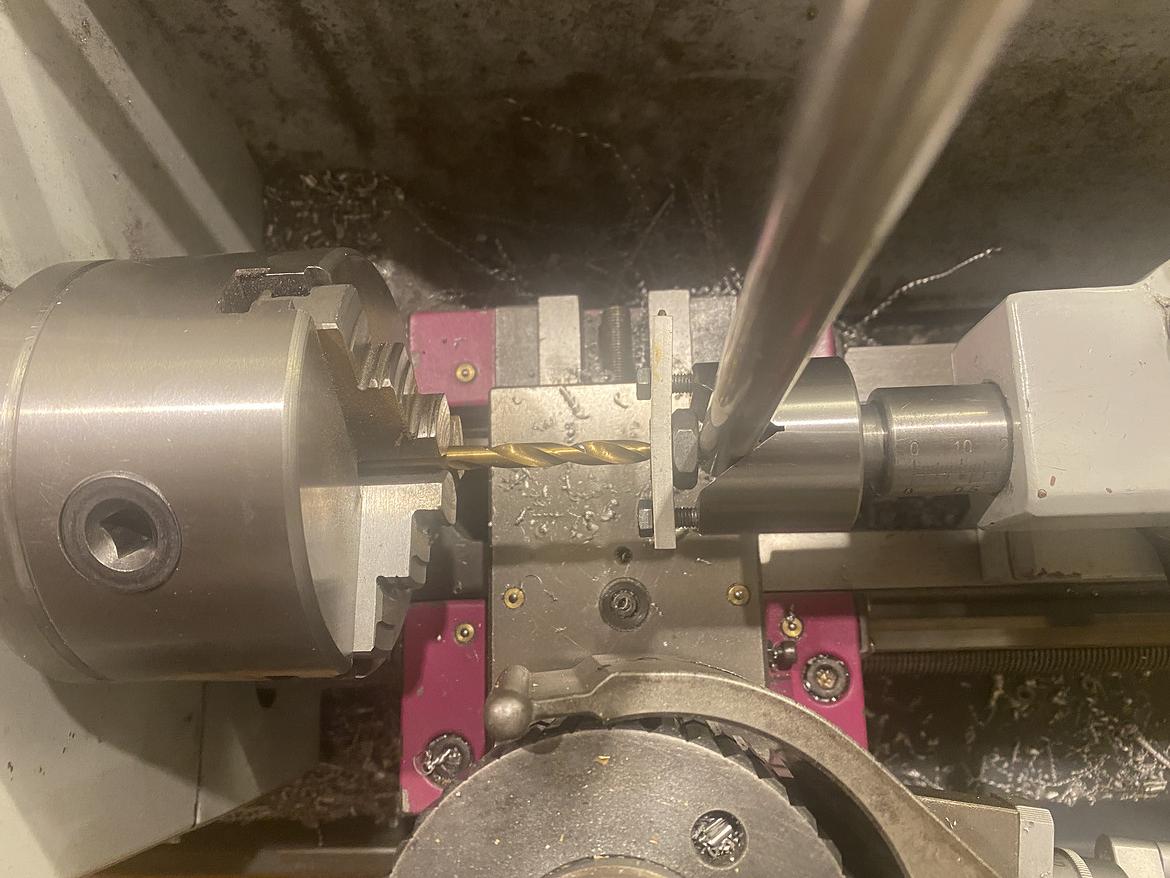

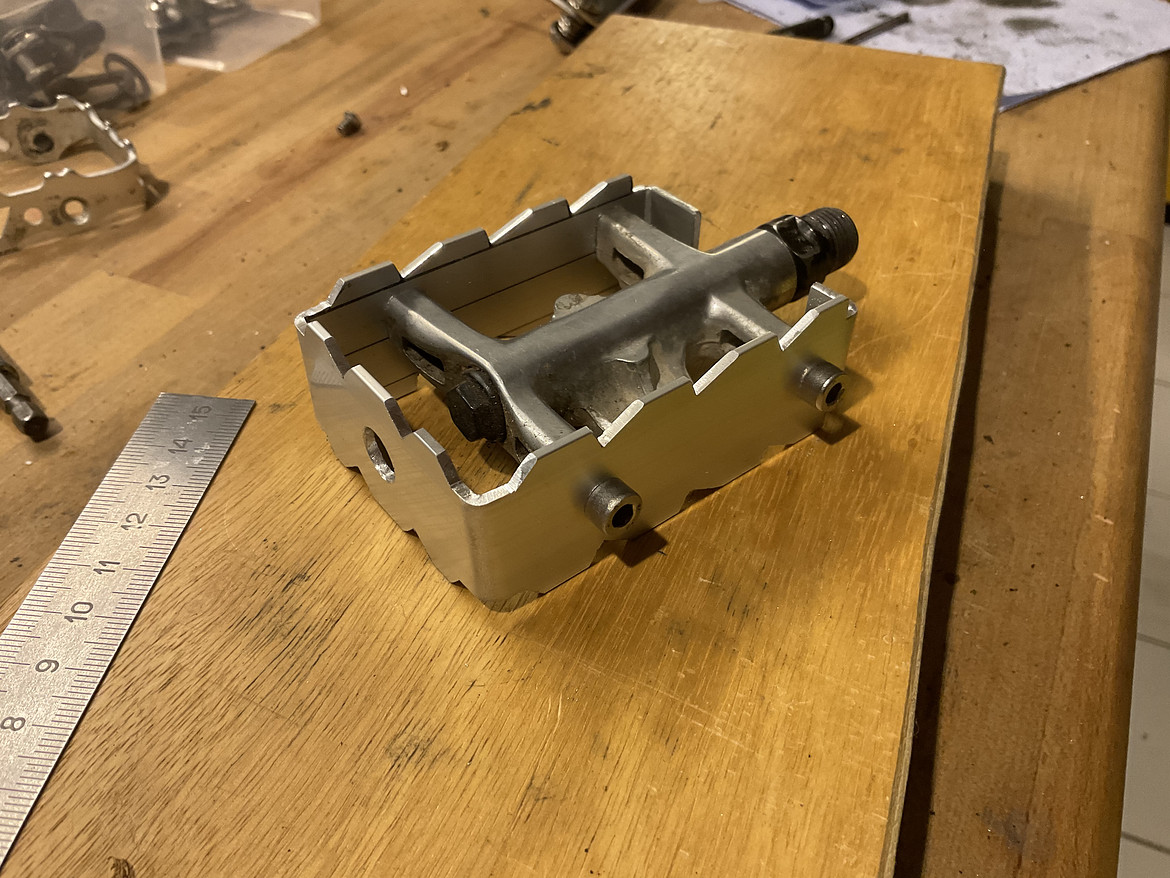

While thinking about that, I started the second pedal.

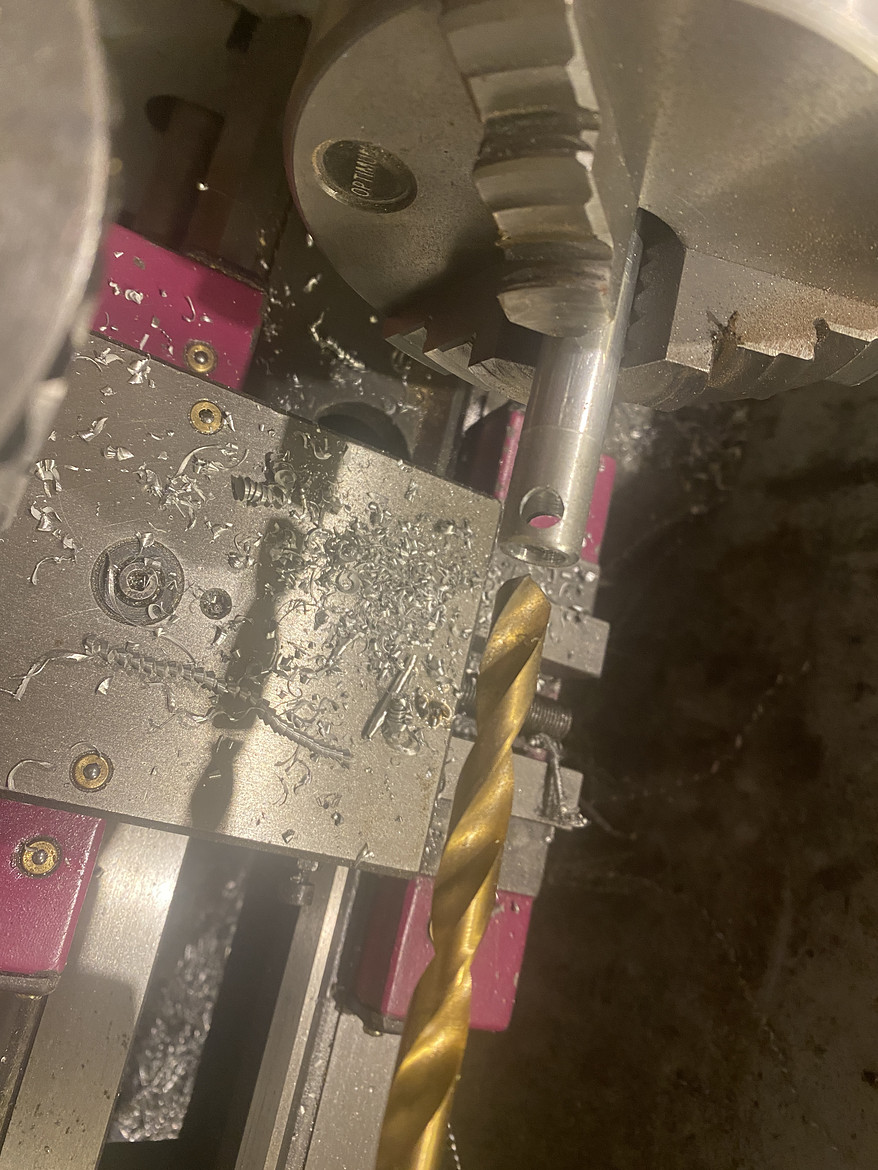

Measure and draw some lines. Then saw and file the access metal. Took me around 1,5h to get to this point.

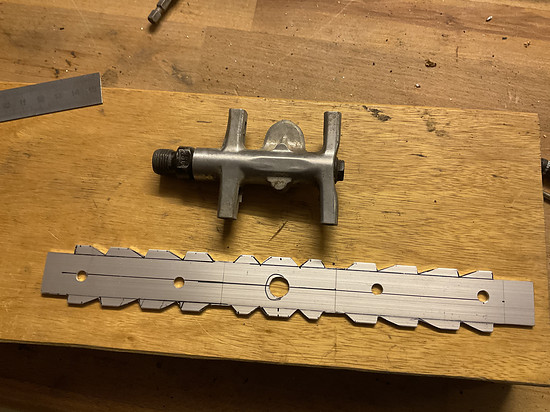

Professional bending machine.

I lost one of the original flat head screws. Took those two normal allen bolts instead. Because i had them. Not sure, I like the looks. What do you guys think?

While thinking about that, I started the second pedal.

Measure and draw some lines. Then saw and file the access metal. Took me around 1,5h to get to this point.

Professional bending machine.

I lost one of the original flat head screws. Took those two normal allen bolts instead. Because i had them. Not sure, I like the looks. What do you guys think?

Last edited: