You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Proshift MKS rear mech help

- Thread starter rwm1962

- Start date

hookooekoo

Senior Retro Guru

Building on one of the previous posts, if your frame has a deep hole chamfer, and the problem is caused by that deep hole chamfer, would it be possible to fix the problem by adding one or more washers? The washers would have to be non-standard, with an external diameter not much greater than the internal diameter, so that they sit in the chamfer, and don't touch anything else. If the washers were any larger diameter, they would most likely cause the same problem you're trying to solve. Looking at some of the pictures posted, the washers would need to sit over the circlip, but be a smaller diameter than the hole in the dropout travel stop (part #10).

A standard dérailleur mounting thread is M10, so if you want to try this idea, you will need to find some M10 shim washers. These shim washers will have an external diameter which is not much greater than their internal diameter, and may just do the job of lifting the dérailleur away from the dropout slightly, so that it is free to move and pivot. Ebay would be a good place to look for shim washers. For example, the listing below offers 10 shim washers that are M10 internal diameter, with an external diameter of just 14mm (a standard M10 washer is 20mm external diameter). Thicknesses available are anything from 0.1mm to 0.5mm. If you choose 0.1mm or 0.2mm you'll be able to tweak the amount of shimming until it's just right.

https://www.ebay.co.uk/itm/114590536320

Let us know if you try the shim washer idea, and if it works or not.

A standard dérailleur mounting thread is M10, so if you want to try this idea, you will need to find some M10 shim washers. These shim washers will have an external diameter which is not much greater than their internal diameter, and may just do the job of lifting the dérailleur away from the dropout slightly, so that it is free to move and pivot. Ebay would be a good place to look for shim washers. For example, the listing below offers 10 shim washers that are M10 internal diameter, with an external diameter of just 14mm (a standard M10 washer is 20mm external diameter). Thicknesses available are anything from 0.1mm to 0.5mm. If you choose 0.1mm or 0.2mm you'll be able to tweak the amount of shimming until it's just right.

https://www.ebay.co.uk/itm/114590536320

Let us know if you try the shim washer idea, and if it works or not.

When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

hookooekoo

Senior Retro Guru

hookooekoo

Senior Retro Guru

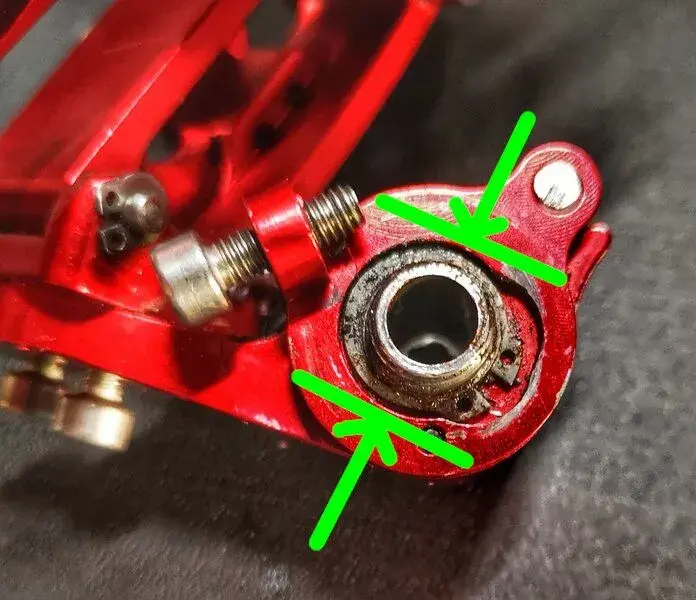

The picture in the first post is much better for illustrating my idea. If the dimension marked in green is a bit more than 14mm, then I think some M10 14mm shim washers will probably work, as they will stop the mounting bolt from clamping the pivot mechanism tight. Normally the circlip thickness should be enough to stop it clamping tight, but in this case, for whatever reason, it's not quite enough and you need a bit more spacing. The minor scrapes to the red anodising on the dropout travel stop (part #10) also suggest that it does need a bit more space to pivot.

Last edited:

I'm the f*ck!ng expert on these!!

I have just spent the past month re-furbishing one that I purchased from the States. It came with a backward mounted B screw and I couldn't really send it back. It wouldn't fit on the bike, so I had to take the pivot bolt out and reverse everything.

It was an absolute nightmare and I couldn't find a tool small enough to open the circlip.

But I managed to get something in the end and work out how the Mk1's all fit together.

It's shame they are not in production anymore because I think I have qualified as a Proshift Technician.

Let me know if you need it cosmetically refurbished.

I have just spent the past month re-furbishing one that I purchased from the States. It came with a backward mounted B screw and I couldn't really send it back. It wouldn't fit on the bike, so I had to take the pivot bolt out and reverse everything.

It was an absolute nightmare and I couldn't find a tool small enough to open the circlip.

But I managed to get something in the end and work out how the Mk1's all fit together.

It's shame they are not in production anymore because I think I have qualified as a Proshift Technician.

Let me know if you need it cosmetically refurbished.

hookooekoo

Senior Retro Guru

Doh! I had to edit my post #15, because I got it the wrong way around. The hole in the dropout travel stop (part #10), needs to be a bit more than 14mm (not a bit less, as I previously said). But you probably worked that out anyway.Thanks. I'm going to get the verniers out later & get some ordered.

I decided to make my own shims from a coke can. I didn't have the tools for M10 with 13mm ID but could do 12mm or 14mm. I was concerned 12mm may have been easily deformed & the 14mm may bind as pretty much same as the diameter of the recess but 4 of the 14mm worked a treat with the bolt nicely tightened up. Previously it was seized solid when that tight. See video below.

Thanks for the tips!

Thanks for the tips!

hookooekoo

Senior Retro Guru

I'm glad to hear that the shim idea worked. And I'm really impressed that you managed to make shims out of such thin material. It was probably much quicker than waiting for a delivery of shims from China. Can you share your method and tooling for making the shims?I decided to make my own shims from a coke can. I didn't have the tools for M10 with 13mm ID but could do 12mm or 14mm. I was concerned 12mm may have been easily deformed & the 14mm may bind as pretty much same as the diameter of the recess but 4 of the 14mm worked a treat with the bolt nicely tightened up. Previously it was seized solid when that tight. See video below.

Thanks for the tips!

View attachment 552704

Similar threads

- Replies

- 26

- Views

- 3K