Betsy

Old School Grand Master

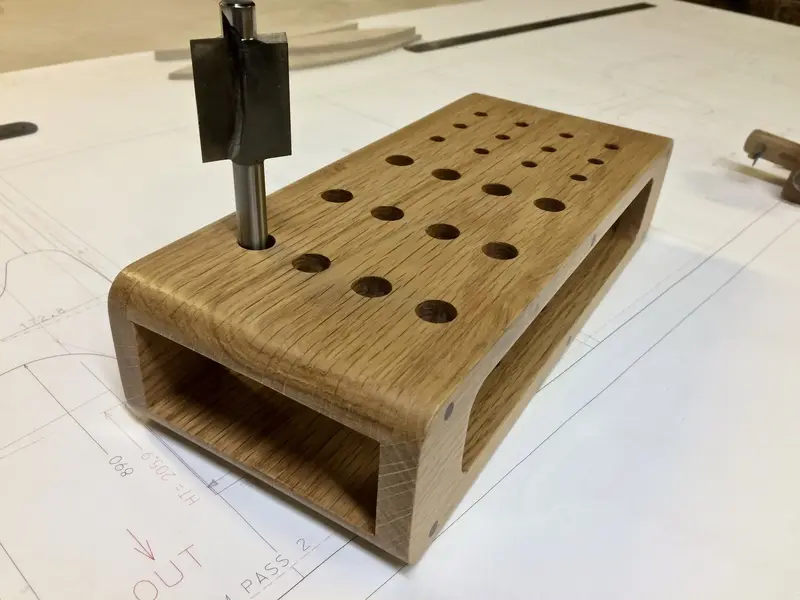

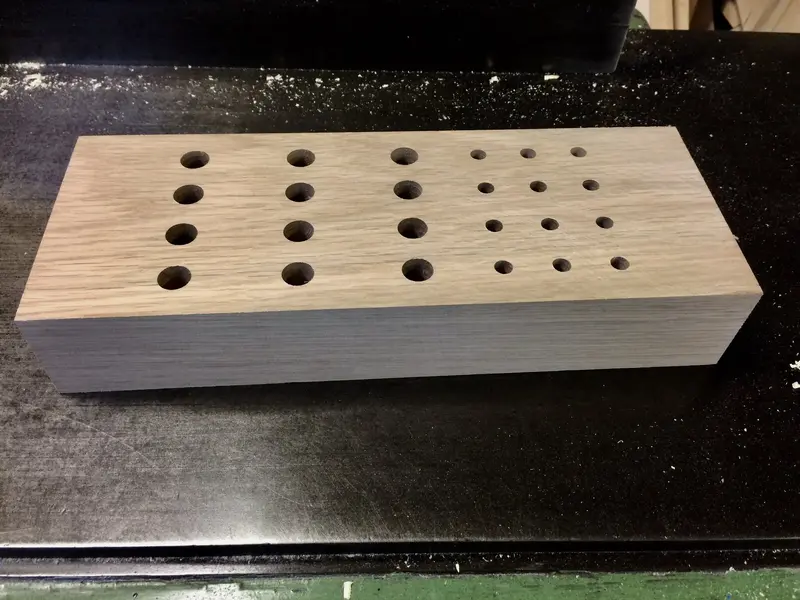

A leatherworker friend of mine, replaced the crappy vinyl headband on my Grado's recently with some lovely hand stitched horsehide.. he wouldn't accept any payment so i made him a little rack for his tools.. he has 12 of these pricks and 12 punches..

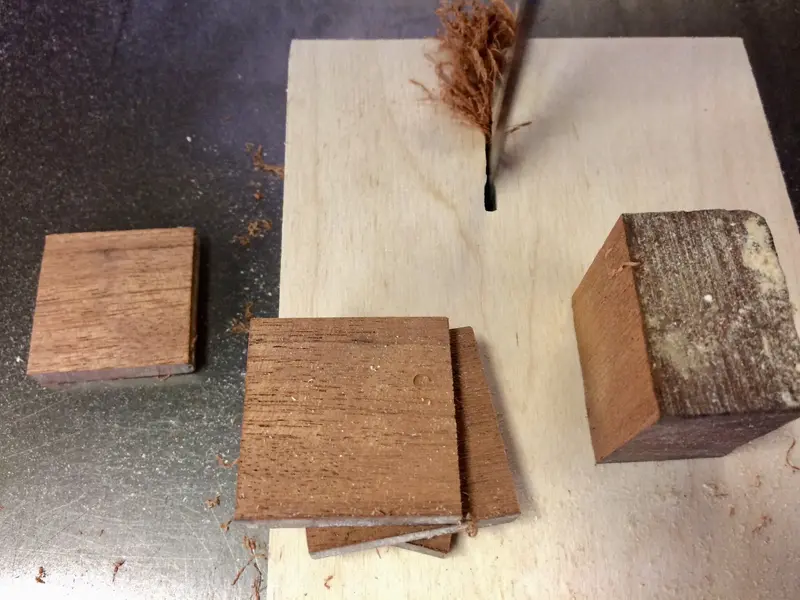

I drilled a plywood template for the holes.. it's easier to get the spacing right on the temp, rather than have numerous confusing lines on your oak.

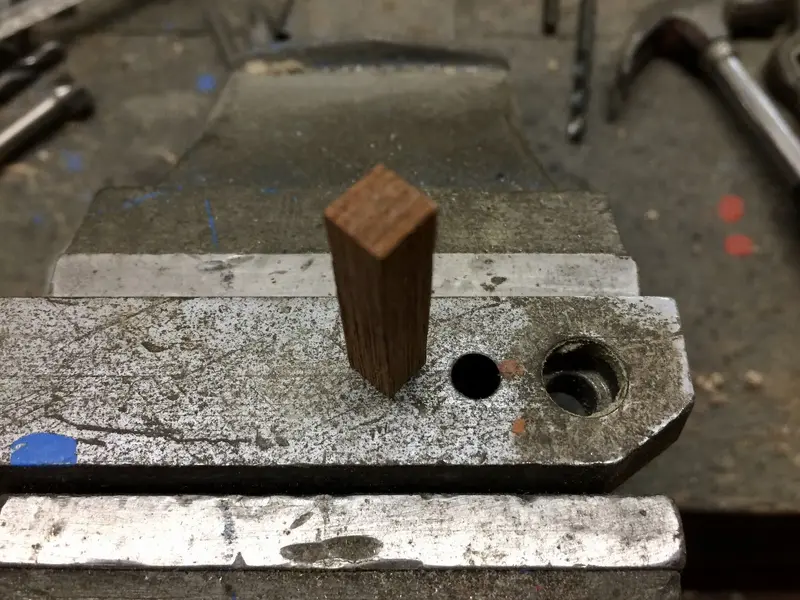

Cut a block of oak from a board and sanded it square.. put the template on top and drilled through the holes.. not all the way through, just a couple of inches down

Used my guage to mark out a 15mm thickness

Cut it off

Sanded it flat..

Repeat

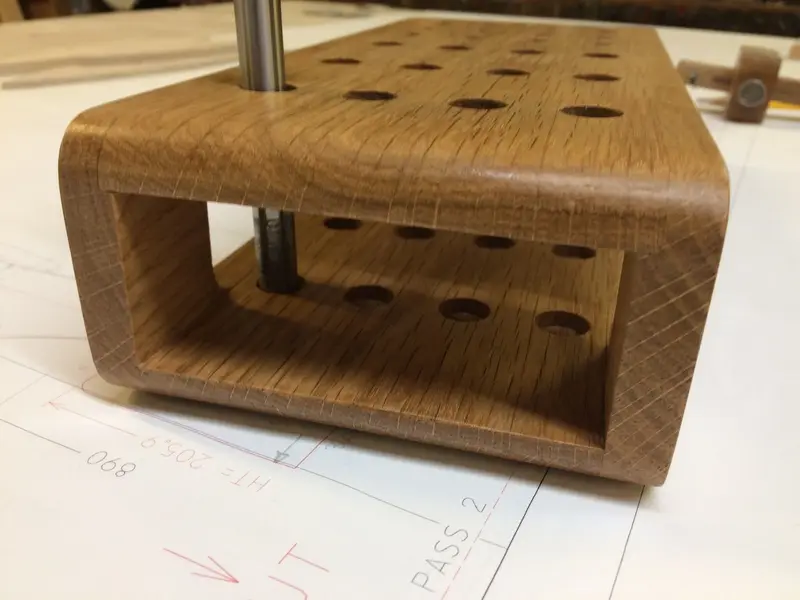

I did the same thing from the bottom of the board (which is why i only drilled 2" deep) giving me 2x pieces of oak with a series of holes on the exact same centers and one piece of oak with no holes to form the base of the rack and laminated the bottom 2x pieces together

..this is only because when i look in the bottom of the holes.. i don't want to see the point left behind from the forstner bit

Pfft.. so unprofessional.. says the guy who can't even focus^ his camera

tbc..

I drilled a plywood template for the holes.. it's easier to get the spacing right on the temp, rather than have numerous confusing lines on your oak.

Cut a block of oak from a board and sanded it square.. put the template on top and drilled through the holes.. not all the way through, just a couple of inches down

Used my guage to mark out a 15mm thickness

Cut it off

Sanded it flat..

Repeat

I did the same thing from the bottom of the board (which is why i only drilled 2" deep) giving me 2x pieces of oak with a series of holes on the exact same centers and one piece of oak with no holes to form the base of the rack and laminated the bottom 2x pieces together

..this is only because when i look in the bottom of the holes.. i don't want to see the point left behind from the forstner bit

Pfft.. so unprofessional.. says the guy who can't even focus^ his camera

tbc..