That's good to know, now a bit less worried about my f3 that will one day get built up.porschenut911":3ozfgayj said:As a TIG welder and long time pace owner I've never been that impressed by the welding on some of the frames. Out of the ones I've owned (100, F3, F6 and 2x 300's) the F3 had the best welding.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rescuing a Pace RC200 F4 Frame

- Thread starter Papillon

- Start date

Bennyboy95

Dirt Disciple

Re: Re:

Papillon

Think it will look cool as a fixiedanson67":4gw8xb1s said:OK...I thought I'd take on this repair for Papillon...

Thankfully, it doesn't appear to have had the seat tube cut out for no reason...That would have been sacrilege.

The original seat tube had cracked around the BB weld:

And later been cut off at the seat tube junction:

Hardly surprising it broke... as the original tube seems to have been a 32mm plain gauge tube with only a 1.3mm wall.

General practice on an aluminium frame would be to run a double-butted tube, 2.2mm-ish at the BB end, 1.3mm-ish in the central section, back out to a short section of 1.6mm at the top, to give a sensible 28.6mm seatpost fit.

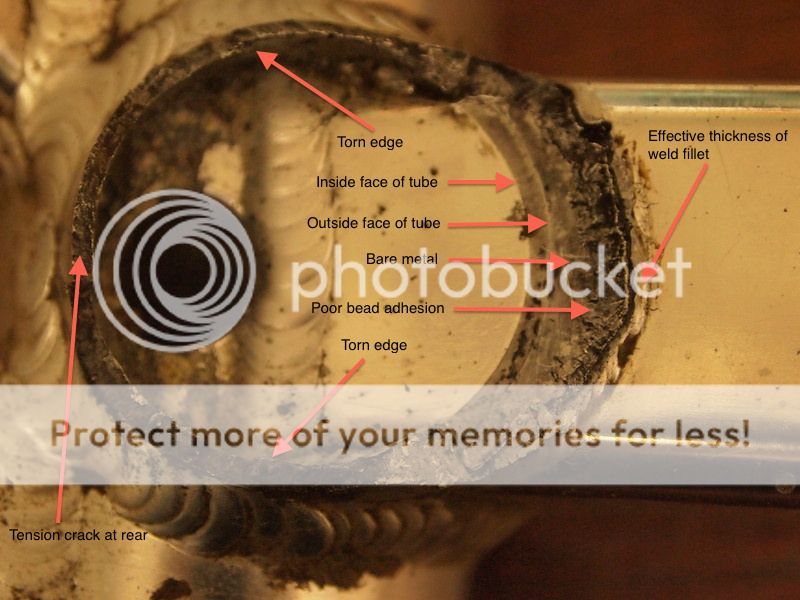

On closer inspection there's some very shallow weld penetration at the front, with a section where the weld pool has touched, but not adhered to, the downtube surface. Also, the eagle-eyed of you will have noticed that the seat tube has been welded on second, after the downtube; the reverse of normal practice with lugless brazed or TIG welded frames.:

I'll be keeping a closer eye on my RC300 after seeing this...

The plan is to clean up the BB shell, removing the anodizing where it will be welded, cut out the stub at the seat end, separate the top ring, replace the pulled helicoil thread and un-anodise:

Clean off the old weldment from the frame tube ends. Then re-weld the top ring onto a new seat tube, with an appropriate 1.3mm wall thickness to be able to keep the original (weird) 29.4mm seat clamp. The upper end of the set tube is well enough supported that I think this should be OK, without the additional strength of a 1.6mm thick butt. We'll see...

Papillon wants me to take off all the cabling and brake fittings to make it more sleek for his fixie project. Offended POP (Pace Originality Police) enforcement messages to him, please

All the best,

Papillon

Alunsworth

Dirt Disciple

Very interested to see how this turns out. There could be another seat tube repair for you Dan!

- Feedback

- View

Re: Re:

Papillon you do know what all fixie uber cool riders are don't you? OXYGEN and THEFT comes to mind so please keep it whole if not for you but for the next owner after you

Papillon":2592wyzq said:Think it will look cool as a fixiedanson67":2592wyzq said:Papillon wants me to take off all the cabling and brake fittings to make it more sleek for his fixie project. Offended POP (Pace Originality Police) enforcement messages to him, please

All the best,

Papillon

Papillon you do know what all fixie uber cool riders are don't you? OXYGEN and THEFT comes to mind so please keep it whole if not for you but for the next owner after you

OK...progress report. Picture heavy:

It's got to get a whole lot worse before it can get better...

1: Cut off tube remains at BB shell. Don't fancy using caustic soda etc, so file and wire brush off anodising around area.

Not great finish, but there are too many nooks and crannies to reliably neutralise the CS in time. Fine for an industrial process, but not here.

Check removal by colour and feel change, backed up with multimeter..anodising is an insulator, so no continuity

Might still need a light blast to remove the anodising completely. Maybe do a small test to assess the slag in the weld pool...

2: Up to the top...Cut into weld roots on the top with small cutting disc on Dremel. Careful, want to keep this bit.

And then cut the tubing I don't want with something a lot bigger...angle grinder + cutting disc:

3: Wiggle, Prise & Lever (that fine company of Solicitors... ) out the stump, taking care to slowly ease apart any remaining weld material. Don't want to kink the tube ends.

) out the stump, taking care to slowly ease apart any remaining weld material. Don't want to kink the tube ends.

This should leave most of the original tube mitring intact:

Ooh, switch the white balance on the camera...that's better

4: Now to get that top clamping section out cleanly. Part off the scabby old tube remains from the clamp at the weld line on lathe.

Small cut on inside of the tube at the thickest section and peel out remaining ring of seat tube:

5: Pull out remains of damaged 5mm Helicoil and replace with new:

One turn deeper than the original. Fully supported, so it shouldn't pull out so easily in future:

6: Quick sand and polish..not too bad. The lower edge will be included in the weld when the seat tube is fitted.

Just have to wait for the replacement tube to turn up now...

All the best,

It's got to get a whole lot worse before it can get better...

1: Cut off tube remains at BB shell. Don't fancy using caustic soda etc, so file and wire brush off anodising around area.

Not great finish, but there are too many nooks and crannies to reliably neutralise the CS in time. Fine for an industrial process, but not here.

Check removal by colour and feel change, backed up with multimeter..anodising is an insulator, so no continuity

Might still need a light blast to remove the anodising completely. Maybe do a small test to assess the slag in the weld pool...

2: Up to the top...Cut into weld roots on the top with small cutting disc on Dremel. Careful, want to keep this bit.

And then cut the tubing I don't want with something a lot bigger...angle grinder + cutting disc:

3: Wiggle, Prise & Lever (that fine company of Solicitors...

This should leave most of the original tube mitring intact:

Ooh, switch the white balance on the camera...that's better

4: Now to get that top clamping section out cleanly. Part off the scabby old tube remains from the clamp at the weld line on lathe.

Small cut on inside of the tube at the thickest section and peel out remaining ring of seat tube:

5: Pull out remains of damaged 5mm Helicoil and replace with new:

One turn deeper than the original. Fully supported, so it shouldn't pull out so easily in future:

6: Quick sand and polish..not too bad. The lower edge will be included in the weld when the seat tube is fitted.

Just have to wait for the replacement tube to turn up now...

All the best,

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 3

- Views

- 3K