Re:

Thanks for the advice.

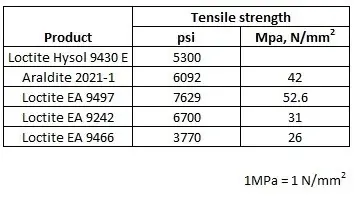

The caps should be bonded to the top of the leg, so doing it again shouldn't reduce any of its functionality i.e. it would be the same as it came from the factory.

I assumed the grooves were there to hold the bonding material that was used previously?

Thanks for the advice.

The caps should be bonded to the top of the leg, so doing it again shouldn't reduce any of its functionality i.e. it would be the same as it came from the factory.

I assumed the grooves were there to hold the bonding material that was used previously?