LumPi Panda

Retro Guru

- Feedback

- View

Good afternoon,Thank you - this is an amazing insight into both your skills and some model making techniques.

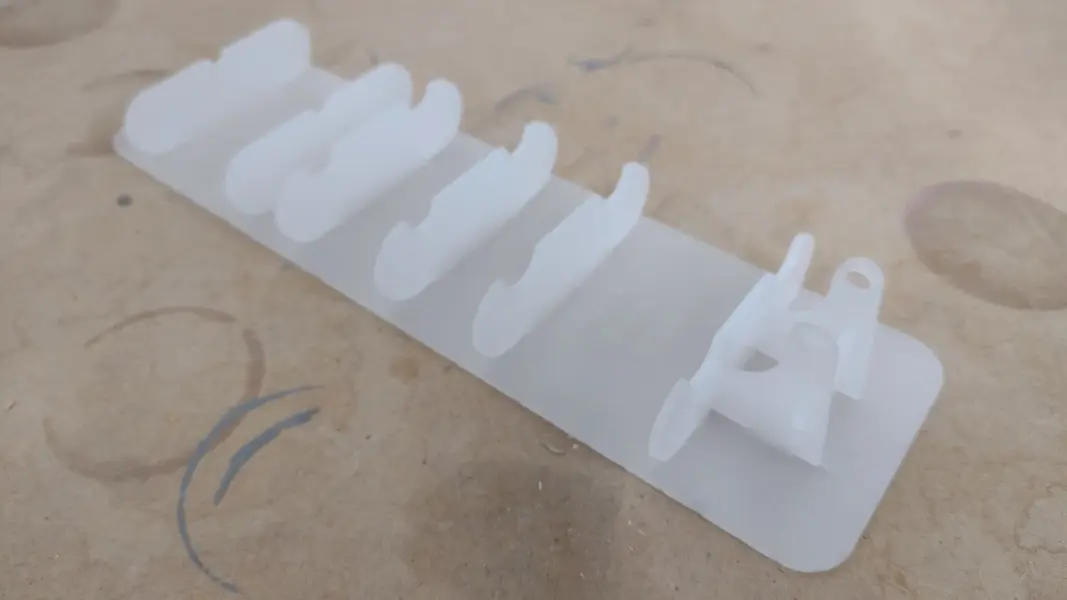

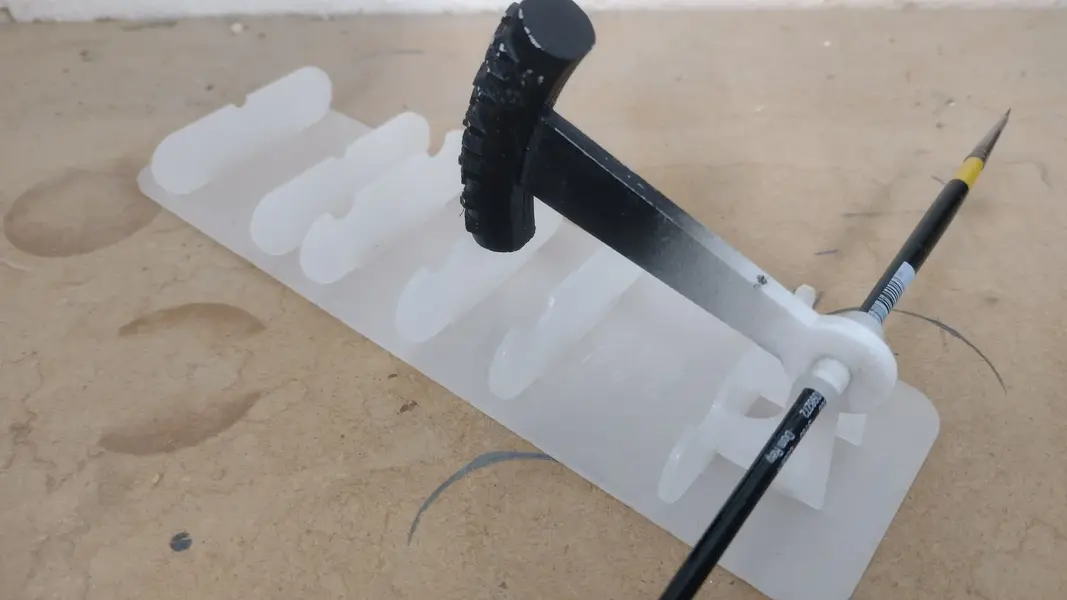

Appreciate this is respective but if there's any way you might be able to incorporate some of the tools, work holding and jigs you use I for one would be fascinated.

Thanks Cloverleaf. It was a lot of effort, but not what I would could hard work. Being an "utter geek" (guilty) I really enjoy this sort of insanity. Even the excruciatingly monotonous bits like all those tyre treads.You're an utter geek and it's bloody brilliant! As someone who's dabbled in various model making genres over the years with very little scratch building, because it's bloody hard work, I can well respect the amount of effort that's gone into this. Awesome.

It would be amusing to see this bike in BOTM. There is nothing in the rules to say the bike has to be 1:1

That thought may have crossed my mind...