lalülala

Retro Newbie

So, i imported this from the UK, i had to have it ever since i learned about it's existence.

After one of the first rides - the pedal fell off... Cross threaded. And it made some pretty bad noises whilst riding. So I took it into the shop, and well - it's got some more issues.

The famous bearing is completely buggerd beyong any saving. I replaced it with a PB10a bearing, this looks like it was specially made for Whyte back in the day.

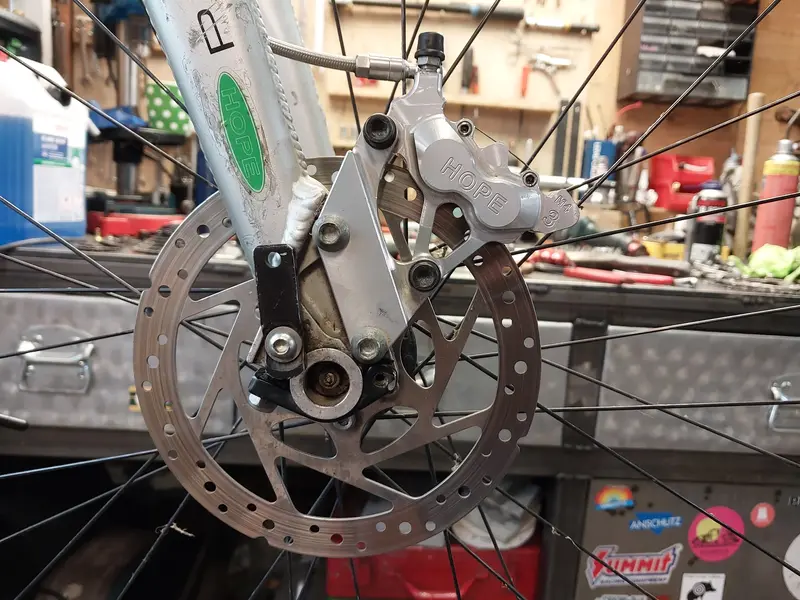

Whilst pulling the rear Hope hub apart to rebuild - I found a snapped axle. Luckily they are available and reasonable cost.

This is at least easy to fix, but I am glad I found it.

These are the easy fixes for this bike. However - it has more major issues which are going to be difficult to adress... Lets start with the rear dropouts:

Adjusters are wound in almost all the way and broken, threads for the lock nuts are stripped. I can't find any real reason as to why that is, all parts look fine. And with wear you'd expect to have to extend the adjusters out. Anyways - that's major issue number 1.

Bring on major issue number 2: the fork. It's twisted.

I was hoping it's just a crooked handle bar, but the fork is clearly twisted in itself. I can't find any crash evidence, I don't know if this is just bad fabrication on Whyte's part of if they are of a weak design. Whyte has not yet responded to my mails.

And last but not least - of course! The frame & rear damper mount are cracked on both sides.

At this point I am not sure how of if to proceed. The frame can get welded. The dropouts - I can make longer extenders on the lathe. But the fork - I am not sure how to proceed here. Finding a replacement seems impossible.

It's a cool bike, it rides fantastic - if anyone has any spare fork they don't need - I am willing to exchange it for some of my hard earned cash.

After one of the first rides - the pedal fell off... Cross threaded. And it made some pretty bad noises whilst riding. So I took it into the shop, and well - it's got some more issues.

The famous bearing is completely buggerd beyong any saving. I replaced it with a PB10a bearing, this looks like it was specially made for Whyte back in the day.

Whilst pulling the rear Hope hub apart to rebuild - I found a snapped axle. Luckily they are available and reasonable cost.

This is at least easy to fix, but I am glad I found it.

These are the easy fixes for this bike. However - it has more major issues which are going to be difficult to adress... Lets start with the rear dropouts:

Adjusters are wound in almost all the way and broken, threads for the lock nuts are stripped. I can't find any real reason as to why that is, all parts look fine. And with wear you'd expect to have to extend the adjusters out. Anyways - that's major issue number 1.

Bring on major issue number 2: the fork. It's twisted.

I was hoping it's just a crooked handle bar, but the fork is clearly twisted in itself. I can't find any crash evidence, I don't know if this is just bad fabrication on Whyte's part of if they are of a weak design. Whyte has not yet responded to my mails.

And last but not least - of course! The frame & rear damper mount are cracked on both sides.

At this point I am not sure how of if to proceed. The frame can get welded. The dropouts - I can make longer extenders on the lathe. But the fork - I am not sure how to proceed here. Finding a replacement seems impossible.

It's a cool bike, it rides fantastic - if anyone has any spare fork they don't need - I am willing to exchange it for some of my hard earned cash.