MuchAlohaNui

Senior Retro Guru

Two frames in this thread, posted this April 2023.

https://www.retrobike.co.uk/threads/bargain-of-the-year-so-far.462505/

https://www.retrobike.co.uk/threads/bargain-of-the-year-so-far.462505/

Intresting.If anyone has one of the aluminum bonded frames. The top tube and down tube were aluminum. A non weldable aluminum. If you look in the bottom bracket shell you will see a spoke nipple. There is a spoke that runs from the head tube to the bottom bracket shell.

Unlike Trek bonded bikes that used a hydraulic jig (for lack of a better word) to hold the frame together while the bonding agent dried. Merida the manufacturer of the MS Racing bikes use a long spoke to hold the frames together.

Also the cable guide on those frames were riveted on the down tube and the hole used to drilled for the rivet is what caused the frames to brake and brake they did.

No unfortunately I do not have any MS bikes or frames.Were these early aluminum frames with the variant that was non-weldable prone to cracking like the later Alpinestars frames? Seems the aluminum was soft, or did they compensate by using thick-walled tubing?

Do you have any personal bikes/frames so you can share a few closeups? I'd be curious. Nonetheless all sounds pretty interesting and thanks for sharing.

Hi, I also found the information from @Rmblfsh very intresting and insightfull.Sorry if some of this was covered, I did not read all 15 pages.

The bikes were sold to motorcycles dealers only. You had to buy a package that included 12 bikes.

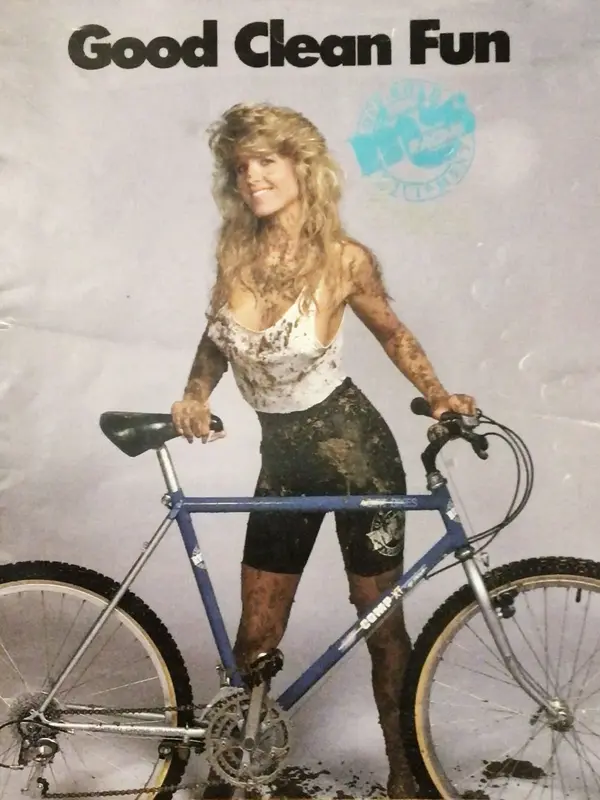

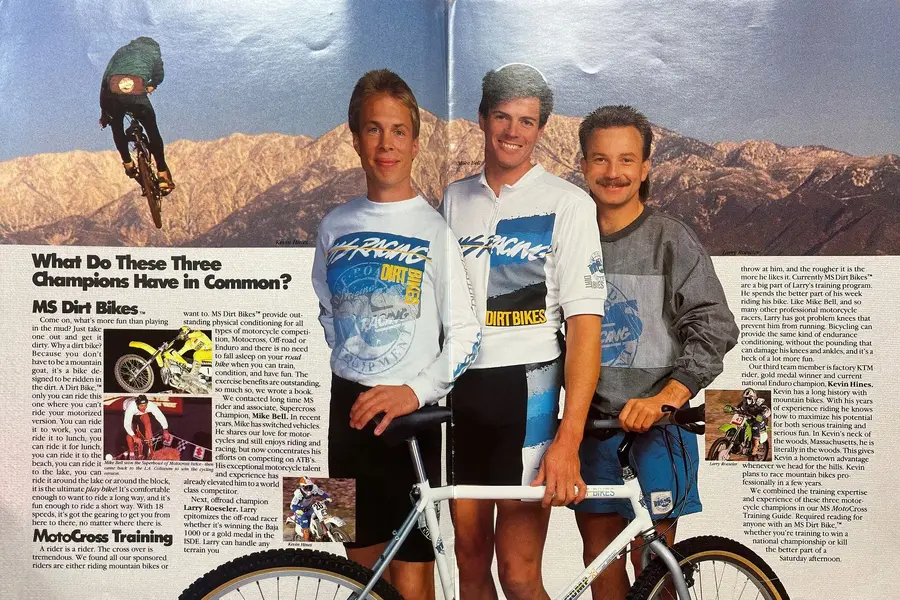

6 of each model. The package was a turnkey mtb deal. The package also included jerseys, shorts, gloves, helmets, water bottles and cages. casual wear, ect… (All MS racing). The package came with display, grid work with hooks, catalogs and posters. The package sold for just under $6,500.00 OAC. Terms were 30, 60, 90 days.

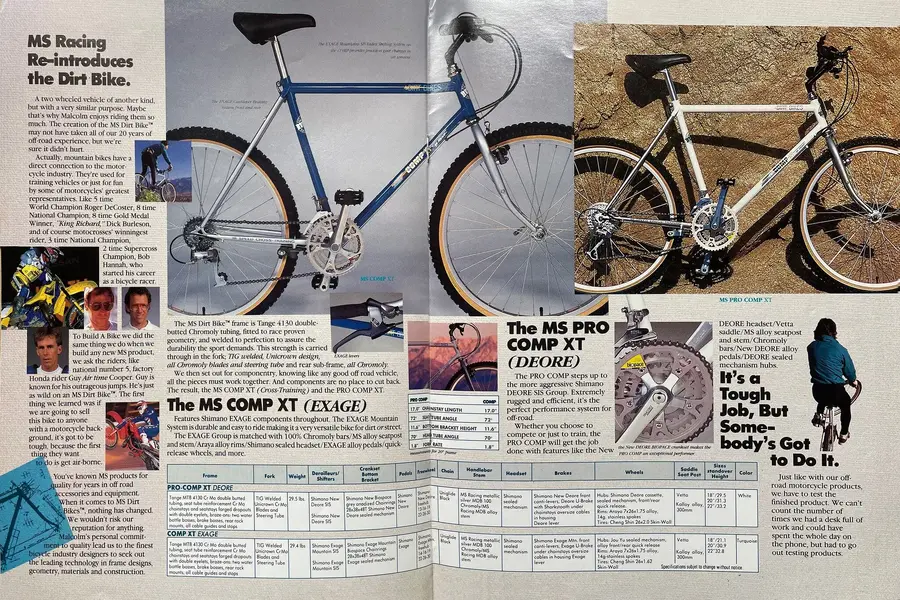

The first year bikes did not come with Deore XT as stated on the first page. The pro comp xt had Deore and the comp xt had exage, There was one production run the first year. 3000 bikes I believe 1500 of each model. I’ll post more later. Pictures are of the first years catalog.