90's Ninja

98+ BoTM Winner

I have a Cannondale Pepperoni fork with a 1" steerer tube that's 40mm too short (if anyone has one with around 150mm of steerer that you want to sell, I'm interested).

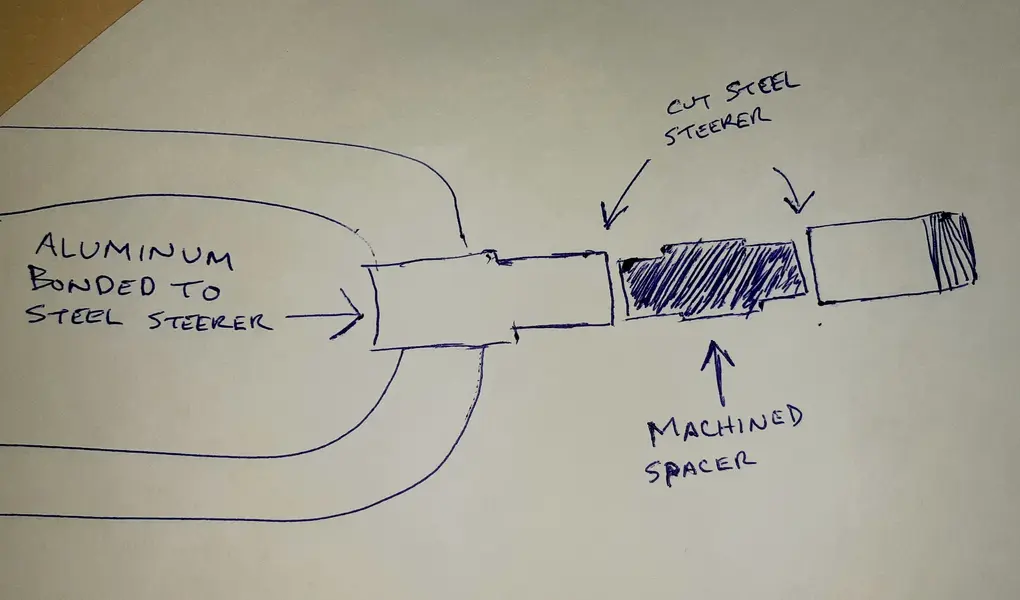

I went to a local machine shop and the guy said that he could machine a solid steel spacer that would sleeve into the steerer 25mm on each side that would be hydraulically pressed in with about 1 ton of pressure. He's confident that it would be a strong joint. He also said that since he'd machine the spacer/ sleeve with solid steel, he thinks that if I wanted the edges chamfered and tig welded, the solid steel spacer would absorb most of the heat from the welding and not harm the bonded joint of the aluminum fork to the bottom of the steerer tube

Anyone with expertise want to chime in on this? Really want a Pepperoni fork for my next project but finding a 1" one with 150mm of steerer is looking to be next to impossible

I went to a local machine shop and the guy said that he could machine a solid steel spacer that would sleeve into the steerer 25mm on each side that would be hydraulically pressed in with about 1 ton of pressure. He's confident that it would be a strong joint. He also said that since he'd machine the spacer/ sleeve with solid steel, he thinks that if I wanted the edges chamfered and tig welded, the solid steel spacer would absorb most of the heat from the welding and not harm the bonded joint of the aluminum fork to the bottom of the steerer tube

Anyone with expertise want to chime in on this? Really want a Pepperoni fork for my next project but finding a 1" one with 150mm of steerer is looking to be next to impossible