Re: Marinovative Decelerators -Who has a pair? (need dimensions)

Looking good!

Looking good!

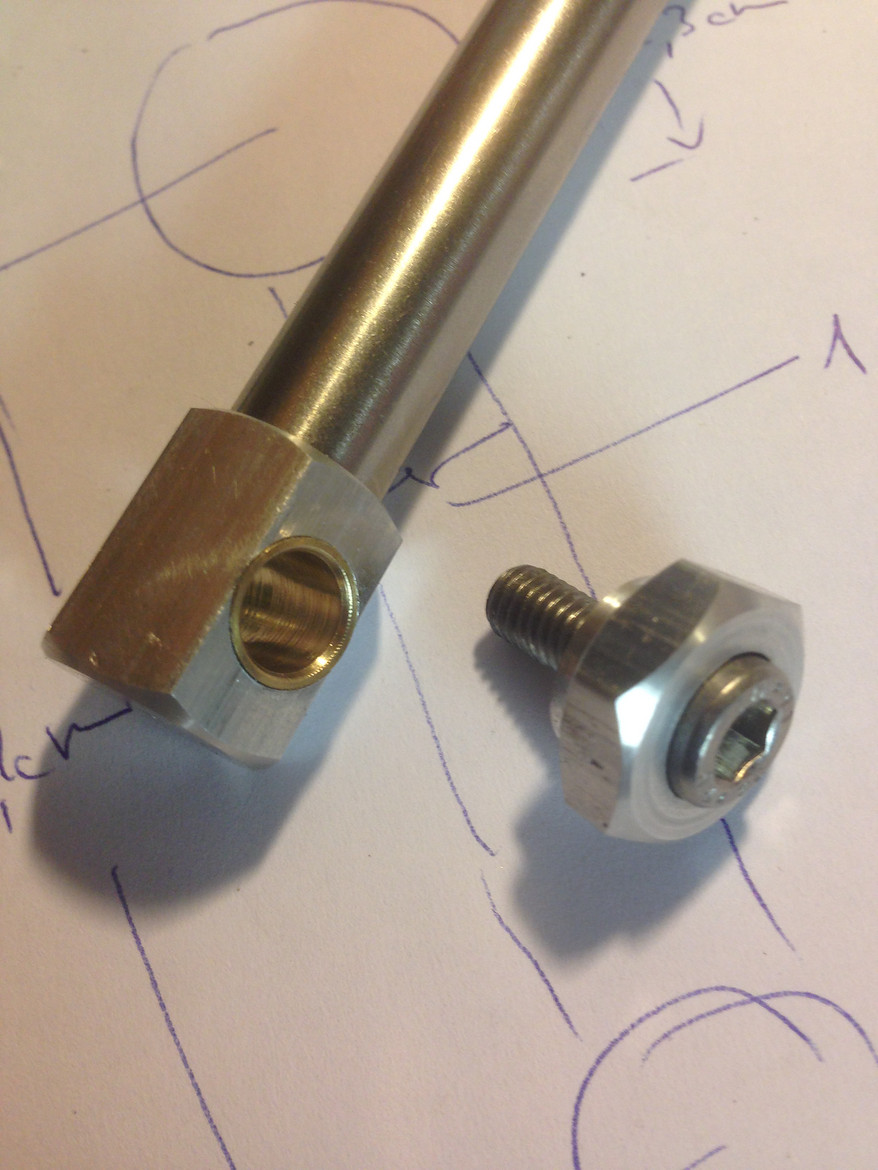

Middle to middle.Did you measure to the middle of the brake stud bolt hole or to the upper edge?