Barnoldswick. It just sounds like a Northern village name. I can’t hear it without thinking of a northern accent saying it. The kind of place you find in a rom-com where Cameron Diaz goes to find herself but finds Ewan McGregor instead. What you actually find in Barnoldswick is Hope.

Barnoldswick. It just sounds like a Northern village name. I can’t hear it without thinking of a northern accent saying it. The kind of place you find in a rom-com where Cameron Diaz goes to find herself but finds Ewan McGregor instead. What you actually find in Barnoldswick is Hope.Pulling up at the house of Hope is quite different from most of the British bike industry I’ve visited. It’s, well, kind of American actually. At least in appearance. Kind of huge in presence and neat in display. You’d never think this gentrified modernised church of British bicycle family silver was actually made in this incredibly smart building, it’s just too nice, too neat, too, well, American. But this front of house is entirely appropriate. To the founders, to the workers, to the ethos, to the product.

Hot northern tea and warm northern greeting escort me around the gallery space in the foyer downstairs. Old shiny things cabinets and retro bikes mingle amongst cutting edge products and furniture made of bike parts. A really nice film about the company plays along side a whole semi-permanent exhibition of various biking photographers’ work. Many names I know in here. Friends on walls. I already feel at home as Co- Founder Ian Wetherill escorts me into the place both physically and spiritually.

And there is spirit here too. A lot of it. I always got that the Hope guys ‘lived it’, but this is a soulful establishment. “When you join the team here, we buy you a bike.” Ian tells me. This ethos is the lifeblood of Hope. As much as a want to produce things here in the UK. As much as wanting those things to be as good as they can be. Looking after people, I get the feeling that’s what it’s all about.

We move into the machining floor and I ask about the building. Turns out, it was an old mill, completely renovated by a printing firm, that pretty much laid it out how a bike component company would need, but lavishly, then went bust. About the time Hope were looking to move. It was a bargain really. Right place at the right time sort of thing I think. “we’d never have been able to afford it if not” says Ian, “it was just an opportunity we couldn’t pass up”. This place is noisy and smelly and industrious like any machine shop, but this one is also really really clean. In fact, it’s kind of sterile. “We invested a lot in having a closed system of lubricants for the machines, so people don’t have to come in contact with the oils. It’s better for the process but mainly it’s just nicer for the people that have to live in that process, day in day out. We don’t tend to do things like this here in the UK generally, this is what I imagine Chris King or Litespeed or Trek do. Or at least that’s what we’re bred to believe. But Hope think differently. Why can’t you make things here? With local craftsmen and women? Out of local materials? All in house, all components, all done here? And make it work. Well, they can. And are. And it does work. That level of thinking, that initiative, that confidence is what’s got £10M of Japanese cnc machines working round the clock to create pedals and headsets and rotors. It’s a matter of belief. And it’s infectious. The people manning the machines believe in it. There’s pride here. Not the usual pride of what once was, but pride in what is. What can be.

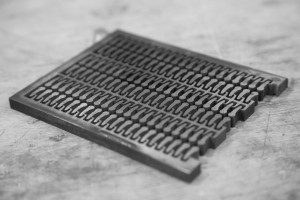

And they should be proud. I am astounded to see the level of attention going into every stage. And there’s a healthy balance too with regards the processes. Cutting edge technology and hand – eye co-ordination mixing it at the highest level and both finding their place on the factory floor. From the incredible 5 axis cnc machines silently performing their moves behind closed doors to the unbelievably manual process of heat treating every single disc rotor, pushing by hand, with a thick pair of gloves and a big wooden stick each one into a red hot press for an amount of time apparently set by the human attached to the gloves.

Ground walnut shells do the polishing, This is in part because they are much less impacting on the environment than the horrific polishing chemicals used in bigger facilities in the far east , and partly to do with the human that has to interact with the process all day long, but it’s also about knowing that actually, no-one’s beaten nature at this yet, she’s just better at polishing things with her walnuts. End of. There’s a kind of tri-thought process here when it comes to the processes. From the anodising experience, to the production of the little aluminium pucks and the extraction of the grease from within them, it’s a kind of balance with nature and best practice for the bean counters never forgetting the people at loud end of the process.

Stringent quality control, robot style. Everything manufactured that has a bearing interface is tested for perfect roundness…

Tour complete, back in the gallery I meet Ian’s wife and son readying a hundred odd goody bags under the Christmas tree. It’s staff Christmas ride out night and it ends up back at HQ to a hamper for each and every member of the team. A nice thing to do, done for nice people, by nice people. Above everything else I’ve seen today, that touches me the most. Quality. Consideration. Care. Good ingredients.

For more on this feature, see issue 11 of Switchback Magazine, available here.

Last edited by a moderator: