You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Frame id needed.. painted over Titanium? Team USA. Nice!

- Thread starter rydelhigh

- Start date

pictonroad

Retro Guru

I bet 99.9% of bike frames are made of a single 'metal'. Mixed construction frames are vanishingly rare in the real world.Can’t help with id of it’s type - but don’t be surprised to find multiple metals - pure one metal frames are few and far between. Often they aren’t found on factory bikes unless they’ve sourced a wholesale supply of specialist build frames built to an OEM spec.

Where you do get factory built cycles with pure build frames, it’s usually the first series (usually short production) using hi grade specialist sourced frames, later production/series use reduced cost less pure single metal frames.

But there are often mixed sections especially around join sections that aren’t one metal due to rigidity/resilience workaround choices.

Try actually designing, and doing the obligatory FEA simulation runs to determine the rigidity and actual stress factors, and you rapidly understand why sometimes the end result of a production frame is less than as pure as the concept.

Believe or not, just building or designing based on theory or baseline designs can equally create an unfit for purpose design even if it’s technically (by theory) bombproof strong.

Just thought it was worth mentioning since the dark magic and sorcery of construction rarely gets mentioned.

Unless you mean the classic 80's marketing special where 'cro-mo' only refer to the tube with the sticker on and it's hi-ten from snout to tail. There's plenty of those.

TheRadioGuyUK

Dirt Disciple

Well given a lot of examples talked about in retrobike circles as the modern end are in the 80s/early nineties generation - there were some serious liberties taken when describing the purity of materials and equally even some hi-ten steel pipe built frames were taking liberties in their claims.

I’ve seen so called hi-ten steel frames that were built out of pipes that be rejected by plumbers (back in the days of iron/steel pipe plumbing) so poor grade they were.

I’ve seen so called hi-ten steel frames that were built out of pipes that be rejected by plumbers (back in the days of iron/steel pipe plumbing) so poor grade they were.

PanoIgano

Fat Chance Fan

This claim would be dependent on the tubeset manufacturer. For the most uknown steel tubeset manufacturers this could be the case.Well given a lot of examples talked about in retrobike circles as the modern end are in the 80s/early nineties generation - there were some serious liberties taken when describing the purity of materials and equally even some hi-ten steel pipe built frames were taking liberties in their claims.

I’ve seen so called hi-ten steel frames that were built out of pipes that be rejected by plumbers (back in the days of iron/steel pipe plumbing) so poor grade they were.

However, I would expect the big 3 - 4 (Reynolds, Columbus, Tange, True Temper) to only produce (in terms of metal mix) what they claim, the majority of which was CROMOLY.

Why would Columbus get in the trouble of producing a prioprietary / patended CROMO variant, the Nivacrom, that's made from Vanadium and Niobium, and claim this in their marketing, if the metals used for Nivacrom weren't Vanadium and Niobium and it was a stranard CROMOLY mix instead?

Not sure, I follow your logic here...just saying.

Last edited:

Chr1st0phe

Old School Hero

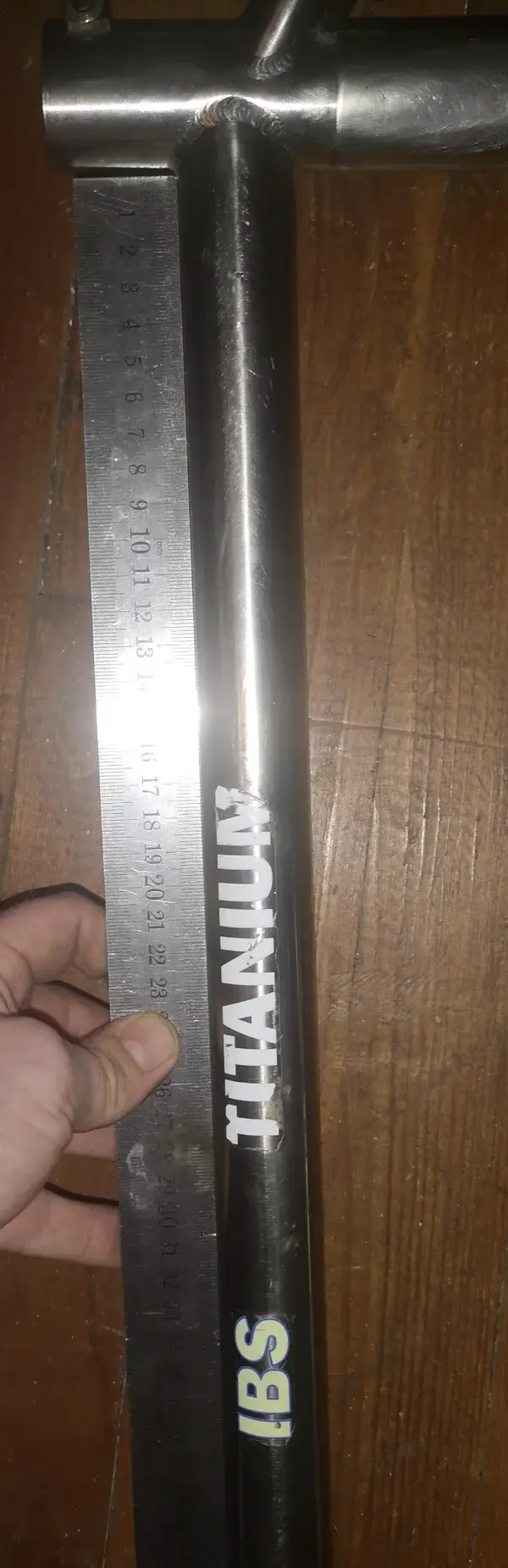

I have to do a microblading so the stickers are removed but I took the measurements.do you have more pictures of this frame? It would be interesting to see IBS's welds and work with titanium.

Attachments

PanoIgano

Fat Chance Fan

Welds are looking pretty good!I have to do a microblading so the stickers are removed but I took the measurements.

I am not an a ti expert in any way but if the Ti alloy used is the same with Sandvik, Merlin and others then that's a pretty good frame I would say.

Last edited:

Uncle Grumpy

Retro Guru

Well given a lot of examples talked about in retrobike circles as the modern end are in the 80s/early nineties generation - there were some serious liberties taken when describing the purity of materials and equally even some hi-ten steel pipe built frames were taking liberties in their claims.

Well given a lot of examples talked about in retrobike circles aren't pieces of crap bike shaped objects sold in department stores, we'd all be keen to hear examples of those brands taking serious liberties taken when describing the purity of materials.

I’ve seen so called hi-ten steel frames that were built out of pipes that be rejected by plumbers (back in the days of iron/steel pipe plumbing) so poor grade they were.

Given how many people here lust over hi-ten steel frames (like... none of us) we'd really like you to back up these claims with some examples.

And remember, your claim was bikes being "mixed metal". What frames have you seen where cheap crap steel pipe has been subbed into place for Reynolds, Columbus, Tange, Dedacciai or True Temper.

We're all keen to know.

Guinessisgoodforyou

rBotM Winner

Can’t help with id of it’s type - but don’t be surprised to find multiple metals - pure one metal frames are few and far between. Often they aren’t found on factory bikes unless they’ve sourced a wholesale supply of specialist build frames built to an OEM spec.

Where you do get factory built cycles with pure build frames, it’s usually the first series (usually short production) using hi grade specialist sourced frames, later production/series use reduced cost less pure single metal frames.

But there are often mixed sections especially around join sections that aren’t one metal due to rigidity/resilience workaround choices.

Try actually designing, and doing the obligatory FEA simulation runs to determine the rigidity and actual stress factors, and you rapidly understand why sometimes the end result of a production frame is less than as pure as the concept.

Believe or not, just building or designing based on theory or baseline designs can equally create an unfit for purpose design even if it’s technically (by theory) bombproof strong.

Just thought it was worth mentioning since the dark magic and sorcery of construction rarely gets mentioned.

The reference to dark magic and sorcery was polite reference to how people treat the invisible complexity that actually goes into the design and engineering of anything that’s not a matter of assembling in the right order and tightening up a few dozen nuts/fasteners out of an idiot-proofed kit of parts.

Clearly anyone with their head screwed on, brain engaged, and actually prepared to try to demystify the stuff that’s actually involved realises it’s anything but dark magic and sorcery. Mind you, half of those probably still pull the escape ripcord when the going gets tough.

Kind of ironic that the former SU was the biggest quantity source of Ti, where a lot of the Ti used on the SR-71 got back door sourced from, yet products utilising Ti in part or whole are rare sights from that part of the world.

I actually owned a military spec SU sourced camera (SLR) that has a full Ti frame and casing - it made most cameras look like toys in construction quality terms. As far as I know, it’s still being used by who I sold it onto.

Are you a solicitor or politician? I've never seen so much BS text that says so little.Well given a lot of examples talked about in retrobike circles as the modern end are in the 80s/early nineties generation - there were some serious liberties taken when describing the purity of materials and equally even some hi-ten steel pipe built frames were taking liberties in their claims.

I’ve seen so called hi-ten steel frames that were built out of pipes that be rejected by plumbers (back in the days of iron/steel pipe plumbing) so poor grade they were.

I would add Raleigh with RSP division.There only were 5 companies in the early 90ties that were able to make titanium frames, I think.

They were Sandvik, Lightspeed, Merlin and Russian company who's name escapes me r.n. And then the (Swiss?) company Revel but they were very niche and did not produce frames for different brands.

So at that time the Sandvik made frames had those characteristic bullet shaped dropouts.

Edit: And I guess there also were a few smaller ones like Lavoie ... and Morati. The russians - were they called IBS? Not sure.

Similar threads

- Replies

- 7

- Views

- 377

- Replies

- 3

- Views

- 558

- Replies

- 11

- Views

- 2K