Final day today, well, half day as the course finishes at 1PM.

Started with a shot blasted frame and forks. Actually really happy with how the brazing and lug lines have worked out. For my first attempt with the torch, it wasn't too sloppy. We fitted a dropout mudguard boss to the underneath of the crown for a mudguard fastening!

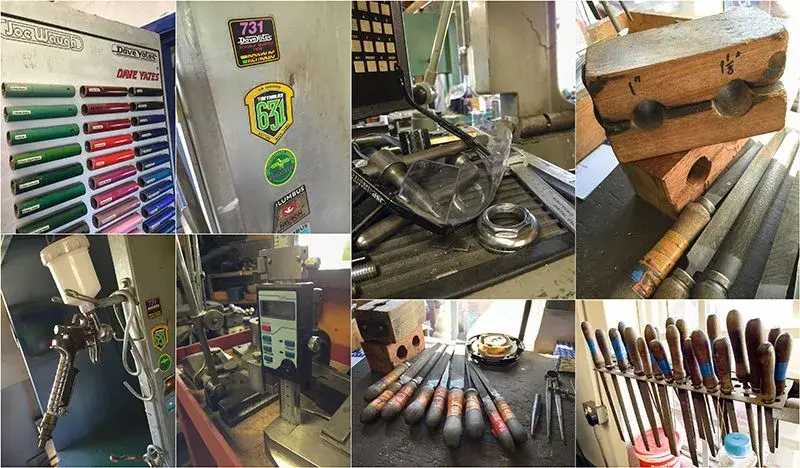

Next job was to file and clean the head lugs and face the head tube. Frame held securely in the hands and faced with a cutting tool in the lathe.

The seat lug gets brazed a few times with top tube, seat tube and seat stays so it was easy for me to cover it in brass that shouldn't have been there. It does file off but just takes time :-(

Another job to do with the seat tube is ream it. The 631 seat tube takes a 27.2 pin. The reamer isn't just removing any snots of brass, it is removing any distortions from the tube that might have formed during heating. A 27.2 fitted in perfectly after reaming.

Finally a few finishing touches...

The inside of the seat and chain stay on the block side is chamfered with a file to allow the bottom sprocket to slide in and out during a wheel change. Dave also has a shaped block of wood and big mallet for fitting chainstay dimples for the inner chain ring clearance. It works perfectly, one big hit and it's done!

During the brazing, we drilled breather holes in both fork blades, the top tube and both seat stays; these are closed up to stop water getting into the tubes. The only hole in this frame is the cut out under the BB. A welding rod is fluxed and placed in the hole and then heated and silver soldered. The rod is cut off and filed smooth.

Finally my 4 and a half day course was over and I had a complete frame and forks

Dave will blast it again and paint it then post it out to me. Unfortunately, I have to wait till sometime in October :-(

I've taken the opportunity to ask Dave all sorts of questions this week. He is very open and answers everything. I have a lot of 753 frames so asked him specifically about 753.

Dave said that 753 certification started with having to build a full frame, (this later changed to just a BB shell seat tube cut off and chainstay cut offs). The full frame was sent back to Reynolds who stress tested it. His first frame received the highest stress figure that Reynolds recorded - so he knows his stuff about 753!

So he said, never chrome 753! Any frame saying it is 753 and has chrome, will, at some point fail. Even chrome dropouts as the tube also receives the chrome and is then painted over to leave the chrome dropout.

Never try to cold set 753, it will snap, at some point.

You can repair 753 but cannot re-track it. Replacing tubes is fine but they need to be put back in while holding the frame in track.

Never spring a 753 frame to take a 130 rear wheel, it will snap at some point. Springing any frame, not just 753, pulls the dropouts out of parallel alignment, fastening the wheel QR then pulls them back in, putting stress on the chain stay bridge and dropout itself. Most failed across the dropout.

He also built, while at M.Steels in Gosforth, a vast amount of frames for other manufacturers and many for Condor. He built the road and track Condor frames for Bradley Wiggins in the early 90s.

He knows other builders inside out and knows how they usually fail - Mercians will often fail across the down tube at the top of the tube just at the butt of the tube. He has examples of other frames and forks around the workshop that he has cut up and they have no brass in them. He has a pair of Lemond forks that have no brass in the crown/steerer joint. It is scary what people are riding around on :-(

My particular fave frame is SBDU. He also had an SBDU frame in a repair, a seized seatpin, with the pin in the vice, he twisted the frame and the seat lug snapped off the frame as there was very little brass holding it to the seat tube.

So not every builder is without issues.

There was loads more about aluminum, titanium, tig welding, his views on fillet brazing. He also makes knife blades and gun stocks and has also made gun silencers out of titanium seat tubes!

Anyway, I'll probably have to leave this thread until I get my painted frame back. Best week I've spent for a long long time

Cheers

Neil