Splatter Paint

Retrobike Rider

- Feedback

- View

Great job!

Ahhhh.....I got it. thank youThat seems about right. There is just a few more little details.

I made some more pictures for clarification:

The most critical part is obviously that puller plate -I call it plate for lack of a better word... I made it out of a larger washer using a lathe. The outer diameter of that plate has to be slightly smaller than the bushing that you want to pull. (30.7mm for the Judy. The bushings are 31mm) The inner hole has to be big enough so the plate can be tilted, as @Motomax correctly described. It is shown in the following picture. That dimension is not critical.

Imagine the bushing still being inside the casting.

The puller plate outer edge should be rather sharp and precise, because the bushings don't have much wall thickness.

Also note the slightly V-shaped filing. Those edges are not parallel, because I found it easier to tilt the plate through the bushing with it shaped like that. One more important thing about that plate is the underside of the outer edge. It has to be rounded, so the plate can rotate back wothout binding against the casting wall. You might be able to spot it in the next picture. The edge of the plate facing the bushing is sharp. The opposite edge is rounded.

To put new bushings in, you will also need a tool. Mine looks like this:

Its a piece of round aluminium with again 30.7mm outer diameter and a step down to 29.9mm. The step fits the new bushing exactly. The steel rod came out of an old printer I salvaged. The new bushing is hammered in pisition using a wooden or rubber mallet.

Don't forget to "form" the new bushings after pressing them in. Or else they might scratch the legs immediately. That step is omitted by many DIYers. But I think it is rather important. Think about the fact, that the lower bushing can only be formed with the upper bushing not pressed in yet! I forget that every time. And then I have to pull the upper one again...

Nice , I have a ITS-2 also. I need a new rear shock bit it looks a bit different than yours : My spring is silver metalfkake and the eye is very round .Do you know if yours is original or is it a replacement? It is hard to get info about them! Mine looks like the attached photo and like the one in the link; https://www.ebay.com/itm/115437563624I have too many bikes! Really.

Now there will be one more, I guess. I'm having way too much fun...

As some may have seen, I'm currently building my LTS Thermoplast.

It has a very wired defect at the rear axle mount. It looks like someone has drilled or filed the slot for the axle. And while it's still possible to mount the rear wheel correctly, it's a hassle to adjust the position every time. And it's also "unworthy" for such a nice frame. So I was scouring the usual spots for a donor frame. I have been for the last few years. And now, finally, one came up. It was ratcher cheap so I snatched it.

This is how it came. BB and original RS Quadra 21R forks. The bushings, especially the one near the bb are shot. But the metal parts are fine. No cracks, no major dents.

Looking at the sad thing, I made the decision to make it my next project.

It beeing a GT, I'm sure it will be really nice when polished. I'm already looking forward to it.

I have too many bikes! Really.

Now there will be one more, I guess. I'm having way too much fun...

As some may have seen, I'm currently building my LTS Thermoplast.

It has a very wired defect at the rear axle mount. It looks like someone has drilled or filed the slot for the axle. And while it's still possible to mount the rear wheel correctly, it's a hassle to adjust the position every time. And it's also "unworthy" for such a nice frame. So I was scouring the usual spots for a donor frame. I have been for the last few years. And now, finally, one came up. It was ratcher cheap so I snatched it.

This is how it came. BB and original RS Quadra 21R forks. The bushings, especially the one near the bb are shot. But the metal parts are fine. No cracks, no major dents.

Looking at the sad thing, I made the decision to make it my next project.

It beeing a GT, I'm sure it will be really nice when polished. I'm already looking forward to it.

Yeah I agree, Do you know what you have? I will look it up .No, I don't think my shock is original. I think it should have been a RockShox deluxe instead. But then again, any short 145mm shock will do.

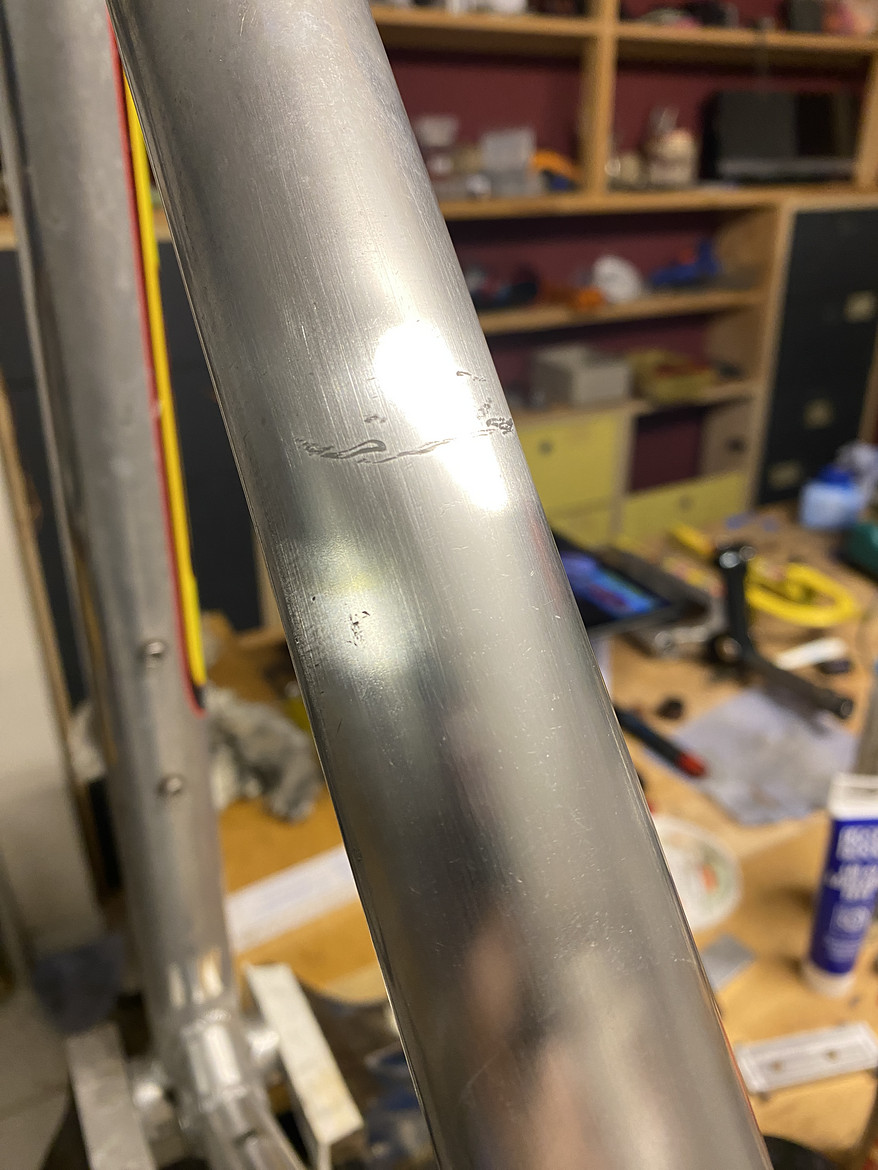

I'd sand it out personally, that spot on top of the top tube is pretty visible. Not sure I'd worry about reducing the wall thickness and would make a gradual thinning a few inches either side. GTs of this era wouldn't have super thin walled tubes would they?There is one deeper scratch on the top tube. What would you guys do? Sand it smooth or leave it?