Thanks all for the replies.

Yes, it's definitely bad, but I am "in it" now, so will probably go a at least a

little bit further before chalking it down to experience. I can live with losing a few quid if I can have a bit of fun with it.

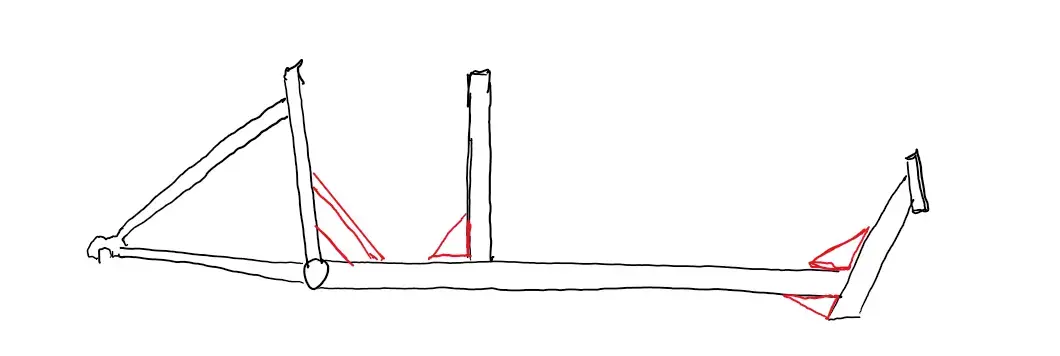

I don't think that the main beam has been cut where the out-riggers are. The out-riggers are sectioned over the main beam (but why they just essentially 'tacked' the out-riggers on is just weird). However, I suppose it can be made solid with some effort. I jumped up and down on the frame last night

and it flexes loads at that silly bolted "joint" detail. The flex has

possibly saved some of the other welds from starting to fail. But I can't imagine how this thing rode. Noodle.

I did take it up and down the driveway, but the steering...well...I'd have to take a video of it. Think Land Rover Defender turning circle and halve it. In fairness, it's very straight and flat where I collected the bike from, but frustratingly there

are corners in my neck of the woods

. I do have some thought's on the steering, which I'll elaborate on further if I make progress on the frame.

Plan is (when I can be bothered), strip it down, take the paint off and clean all the joints up. Then it'll have to go up to my brothers unit for the work to begin. I

won't be welding this. I'll do the grinding up, make the gussets etc and possibly tack them on, but I'd want the welds to be strong, so it'll be left to someone who knows what they're doing, to give me some confidence that it has some strength!

Onwards...........