Hi everyone, back from a trip to Italy, I was talking to my cousin, a keen road cyclist, and he said they extend steerer tubes all the time by threading them.

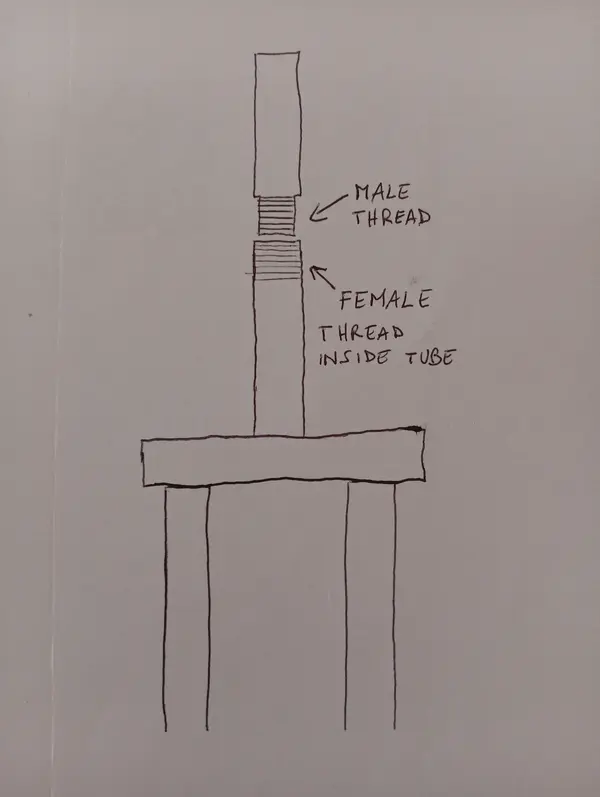

He drew this for me...

He said that once tightened with red thread lock, it never comes out again.

Steel steerers can also be welded after being screwed in.

I understand that road bikes don't have that many vibrations compared to MTB, but to me it sounded like an easy and safe plan.

Maybe I would use epoxy adhesive for a permanent job, but apart from that ...

What do you think?

He drew this for me...

He said that once tightened with red thread lock, it never comes out again.

Steel steerers can also be welded after being screwed in.

I understand that road bikes don't have that many vibrations compared to MTB, but to me it sounded like an easy and safe plan.

Maybe I would use epoxy adhesive for a permanent job, but apart from that ...

What do you think?