Thank you - this is an amazing insight into both your skills and some model making techniques.

Appreciate this is respective but if there's any way you might be able to incorporate some of the tools, work holding and jigs you use I for one would be fascinated.

Thanks Lucidone,

Of course. Tools are fairly straightforward;

Hands. I have two of these, but one was holding the camera. It looks pretty similar to this one, but the other way around.

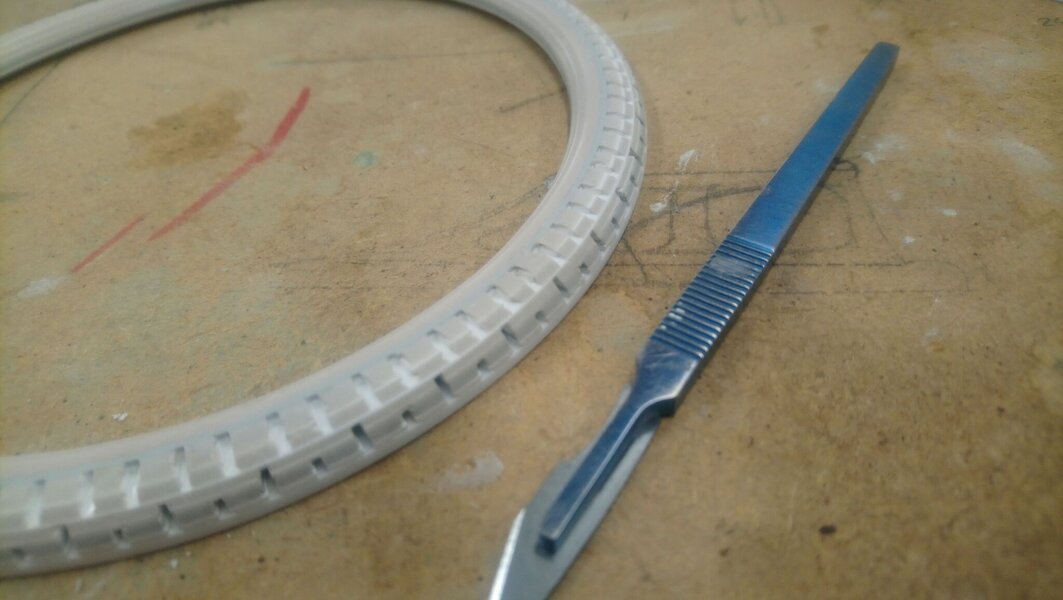

Scalpel - indispensable.

Tweezers - in a variety of shapes and sizes.

Accurate rule - useful for prising lids off paint.

Reverse action tweezers - extremely useful for holding small things while sticking other small things to them.

Brushes - also in a variety of shapes and sizes.

That's about it for hand tools apart from various grades of abrasive paper, usually double sided taped onto various shaped sticks.

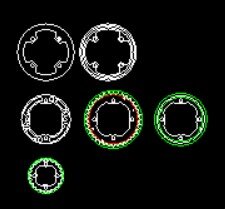

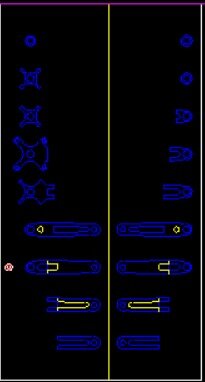

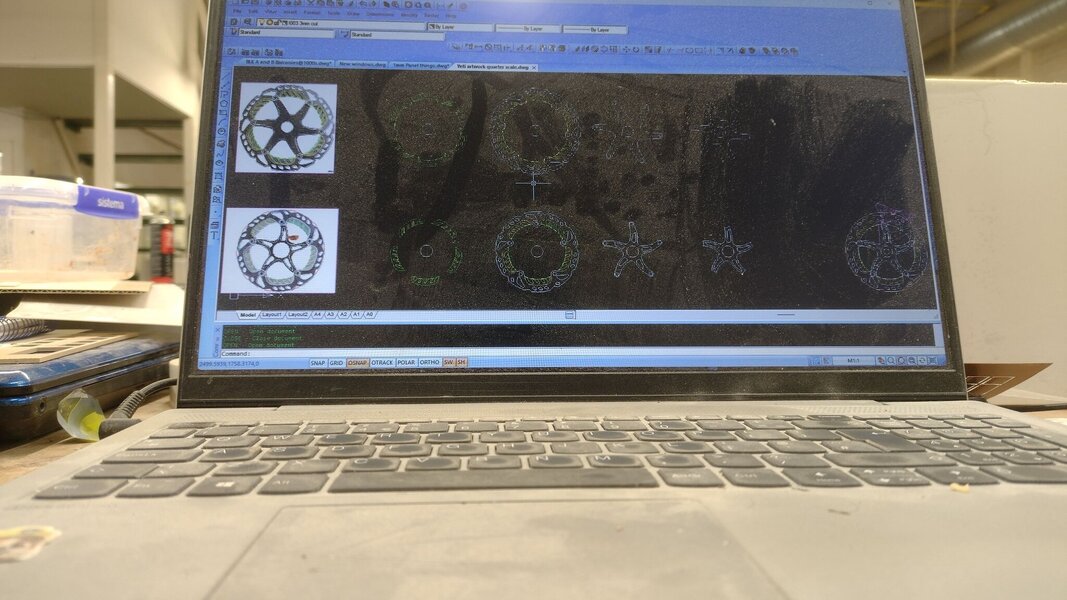

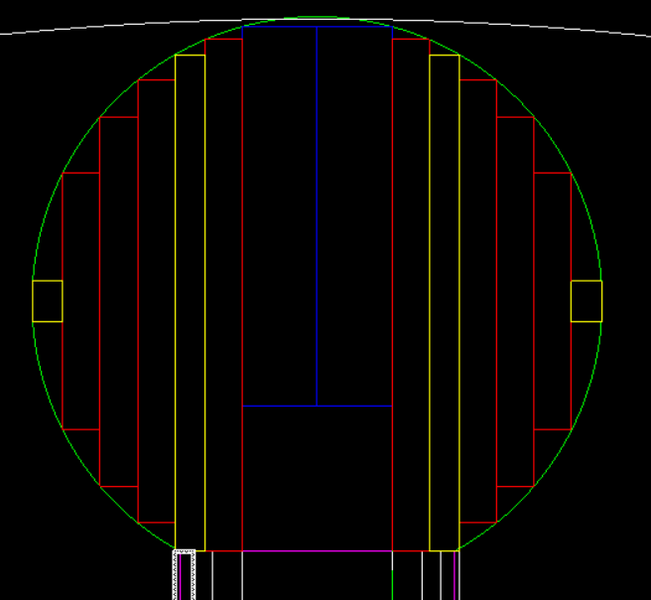

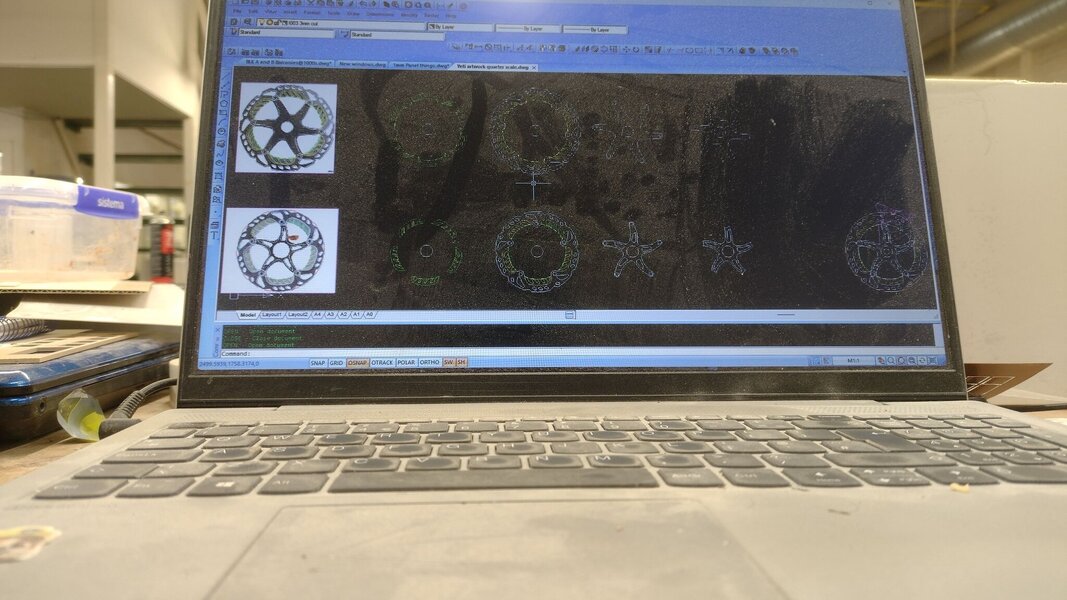

CAD. How did anyone make anything before CAD?

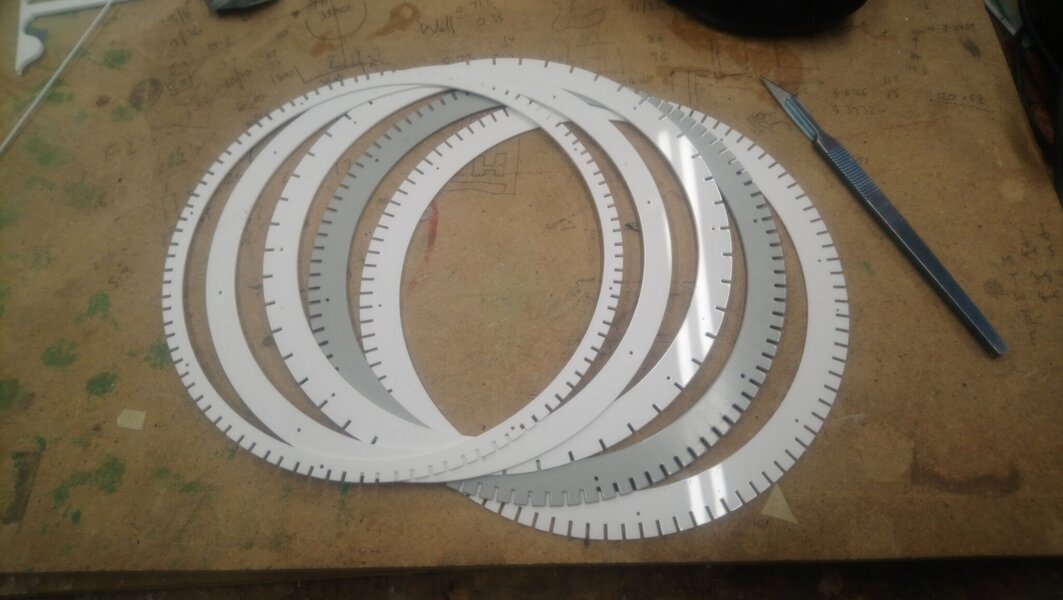

Big frickin' lasers. Didn't need to be this big, but that's what we have at work. If I had a smaller one at home I would probably have already made a couple of other bikes by now.

I still have all of the jigs, moulds and patterns in the loft at home. I'll dig them out if you're interested.

Also, stay tuned for the wheel building bit later on. Some pretty bad-ass jigs in that bit.