I was reading the braking performance of chrome rims is not great, Having never ridden anything like this, with about 20+ years riding MTB (usually with very good traction and braking) I'tll probably catch me out at some point!

I'd never heard of such a thing as leather pads until you mentioned it - but now I've looked I see a few suggestions that these are actually best choice for steel rims, particularly in wet...- as most rubber compounds sold are aimed at use with alloy rims and really unsuitable .... Still learning over here...

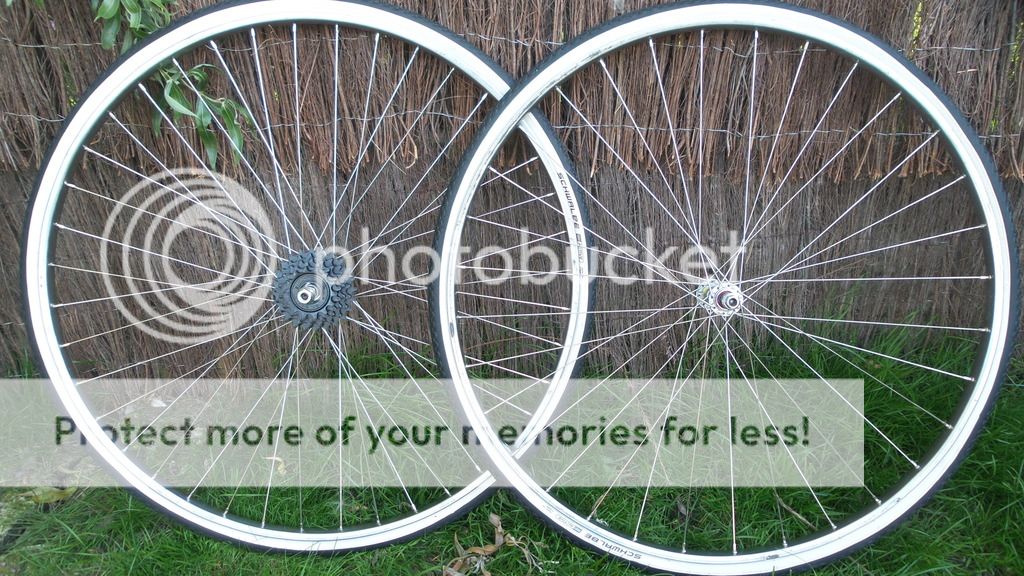

I've looked into the options for ages, and passed on the champion, as I couldn't seem to get the right lengths sadly. I brought Sapim lasers in the end thinking the 2.0,1.5,2.0, against the original 1.8,1.4,1.8 rustless spokes seemed a reasonable compromise

I've put them up against the hub today, and I think I finally understand the issue that causes weakness. With relatively slim hub flanges of the older rims, the larger bend radius of the thicker guage means that the spoke elbow ends up slightly gapped away from the flange, rather than being flush against the flange as would be desirable. Spoke washers would almost certainly help correct for this, and are available, so I've ordered some up. Another learning curve...