Gave my freehub body from Deore DX hub a full service but sadly managed to destroy one of the freehub bearing adjustment washers and already threw it to the trash. It was thinner than paper...

Now, the freehub system gets rough even after finger tight torque on the bearing cone.

Is there a way to reproduce the washers somehow? Aluminum cans or can I buy something similar at a tool shop?

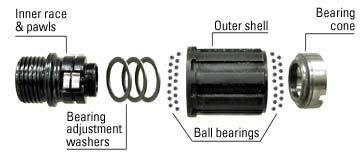

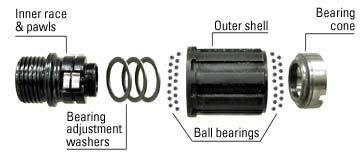

Image from Park Tool webpage.

Secondly, something anomalous happened with the hub bearing surface after sinking the bearing cone in degreaser for a night. The surface looked almost perfect but now it has black pitted spots as if the chrome came off.. Did I do anything wrong or it was about to pit and degreaser just fastened the process?

Most probably there isn't a spare part for the bearing cone am I right? The faulty freehub belongs into the spare parts bin..

First time freehub overhaul lessons learned....

Now, the freehub system gets rough even after finger tight torque on the bearing cone.

Is there a way to reproduce the washers somehow? Aluminum cans or can I buy something similar at a tool shop?

Image from Park Tool webpage.

Secondly, something anomalous happened with the hub bearing surface after sinking the bearing cone in degreaser for a night. The surface looked almost perfect but now it has black pitted spots as if the chrome came off.. Did I do anything wrong or it was about to pit and degreaser just fastened the process?

Most probably there isn't a spare part for the bearing cone am I right? The faulty freehub belongs into the spare parts bin..

First time freehub overhaul lessons learned....