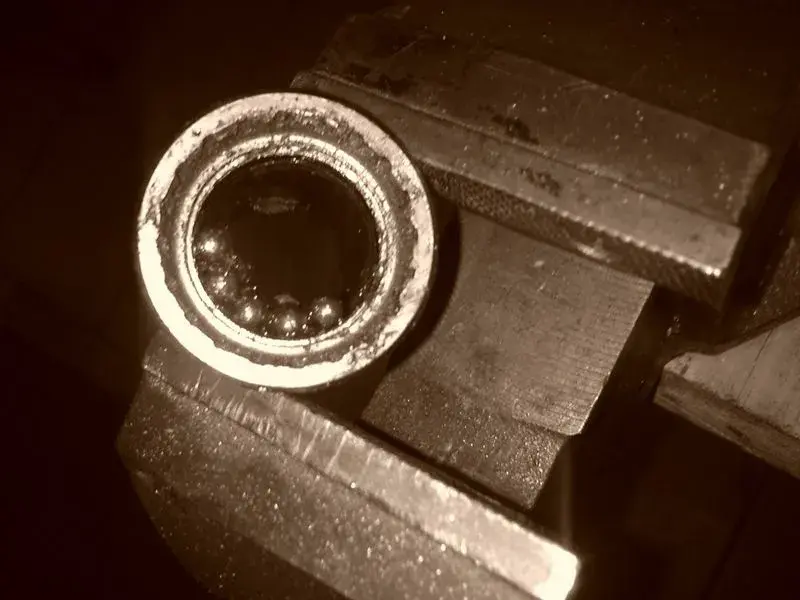

Sharing some Friday entertainment in the man cave. We've all wondered what's inside a Shimano Sealed Cartridge BB and how's it made. It's been done numerous times before to break in them, but here is one technic.

The subject for euthanasia is a knackered UN52 68/107mm. God bless.

Initially, I was going for the usual crow-bar angle grinder lump hammer approach. I started with a lump hammer first, but to no avail. I realised that is was best to coerce it to pieces rather than blugeon it to pieces.

Using ambassadorial skills and exploiting weeknesses, it can be pulled to pieces using just a Precision Srew Driver and Bench Vice. EDIT: Oh, and a drill

The subject for euthanasia is a knackered UN52 68/107mm. God bless.

Initially, I was going for the usual crow-bar angle grinder lump hammer approach. I started with a lump hammer first, but to no avail. I realised that is was best to coerce it to pieces rather than blugeon it to pieces.

Using ambassadorial skills and exploiting weeknesses, it can be pulled to pieces using just a Precision Srew Driver and Bench Vice. EDIT: Oh, and a drill