Thias

Klein Fan

It's been a while since I last did a build thread here on retrobike. I blame it on the language barrier...

So. This time round I had to scratch the itch and buy back some of my childhood memorys.

My first "proper" mountainbike that I bougt new around 1991. I think.

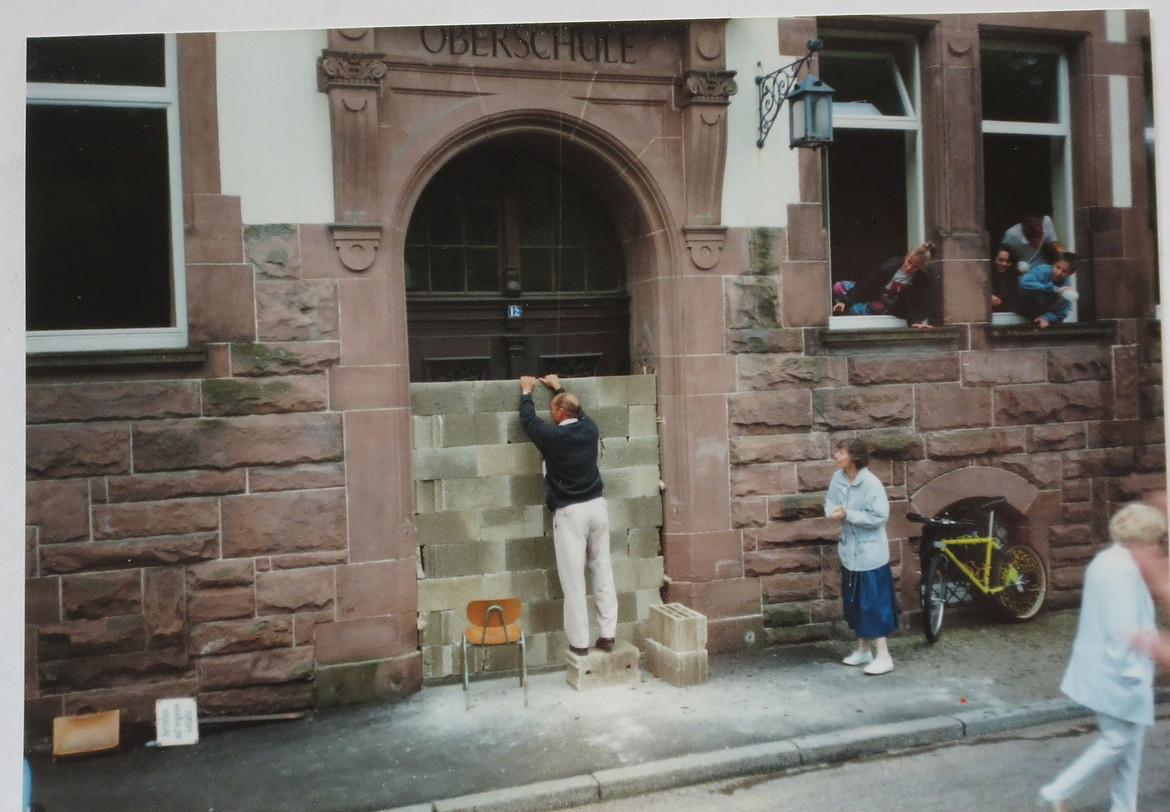

Here is my only picture of it in 1993. I stumbeled across that picture while clearing my mom's flat.

Of course it had a set of "horns" bolted to the bar. You can't see it in the picture, but I did a lot of weight reduction to those, buy drilling tens of holes into them.

Then again - completely forgetting about the weight - I had to fit these wheel covers to the back. Because I had seen some famous rider in the magazine riding them tensions disks...

[OT] If you are wondering what the hell is going on in that picture: It's a german custom that on the last day in school the class stays in the building over night and prepares some kind of prank for the teachers. In this case some concrete brickage and - of course - water baloons... [/OT]

I really loved that bike back then. I learned the ropes of repairing your own bike. It had a shimano 200GS. Didn't last long. I had to replace the hubs soon.

The rear derailleur was ripped off at some point. And it was quite the hassle to get a replacement. A used XT one that I found in the ad section of our newsletter. Remember these?

I had to ride 20km to the next town to get it. And I had to borow that puny 20" foldable bike from my dad for the trip. No fun, that.

Anyhow. I managed to get my hands on a very nice example of on of those bikes for cheap. Ah, the wonders of the internet.

This is the beauty, as I got it a few weeks back. Very mint condition. No rust. No fading in the paint.

Just a glorious neon paint with dark splatters.

I love it.

The plan is to strip it completely. Then use all the stuff on it, my 13 year old self used to drool over bitd.

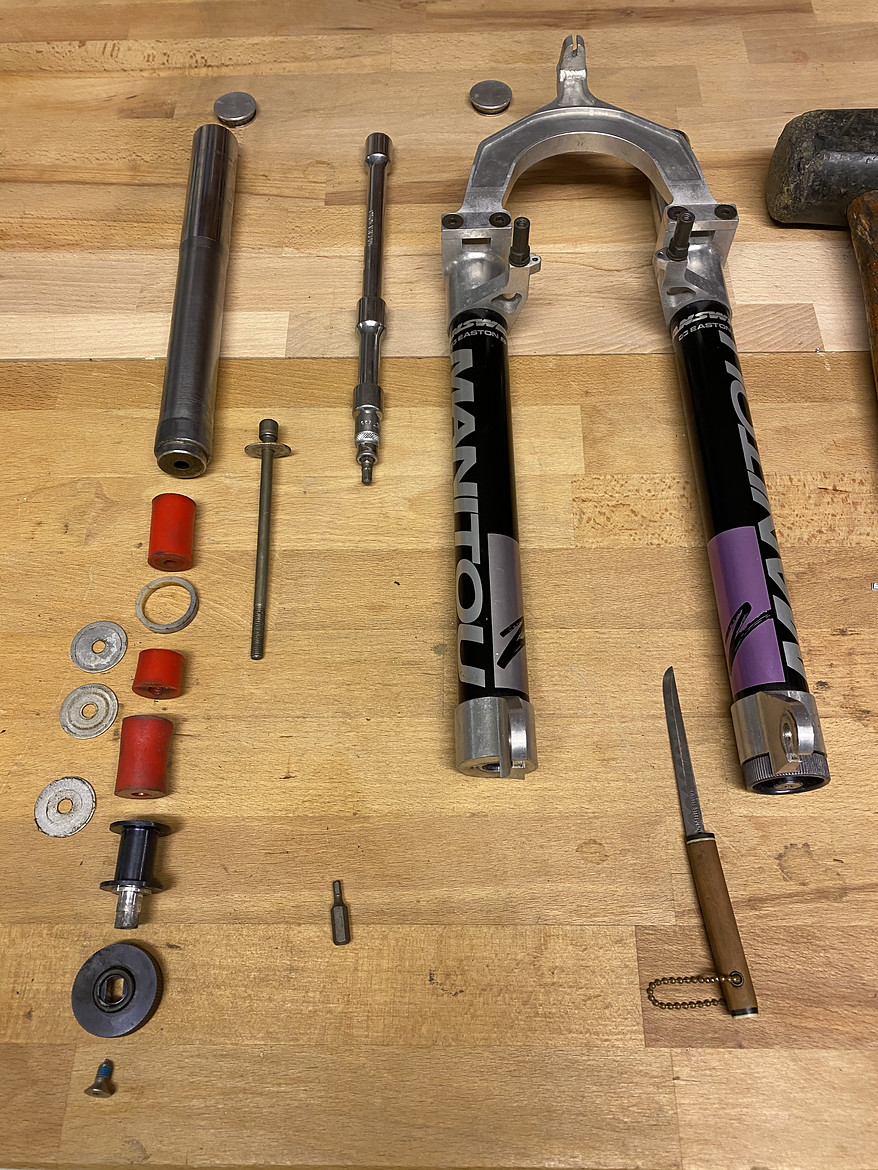

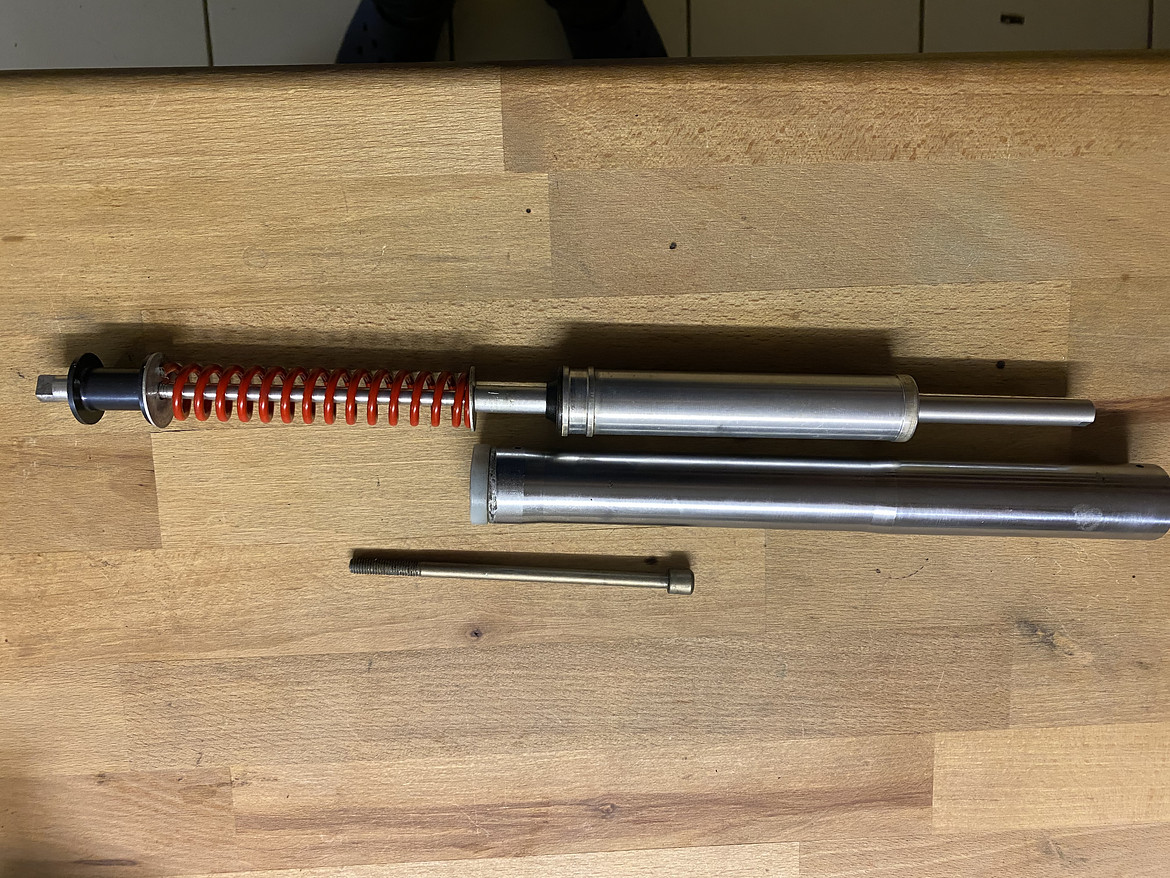

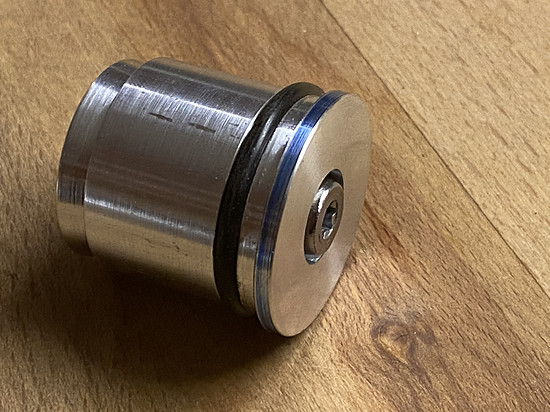

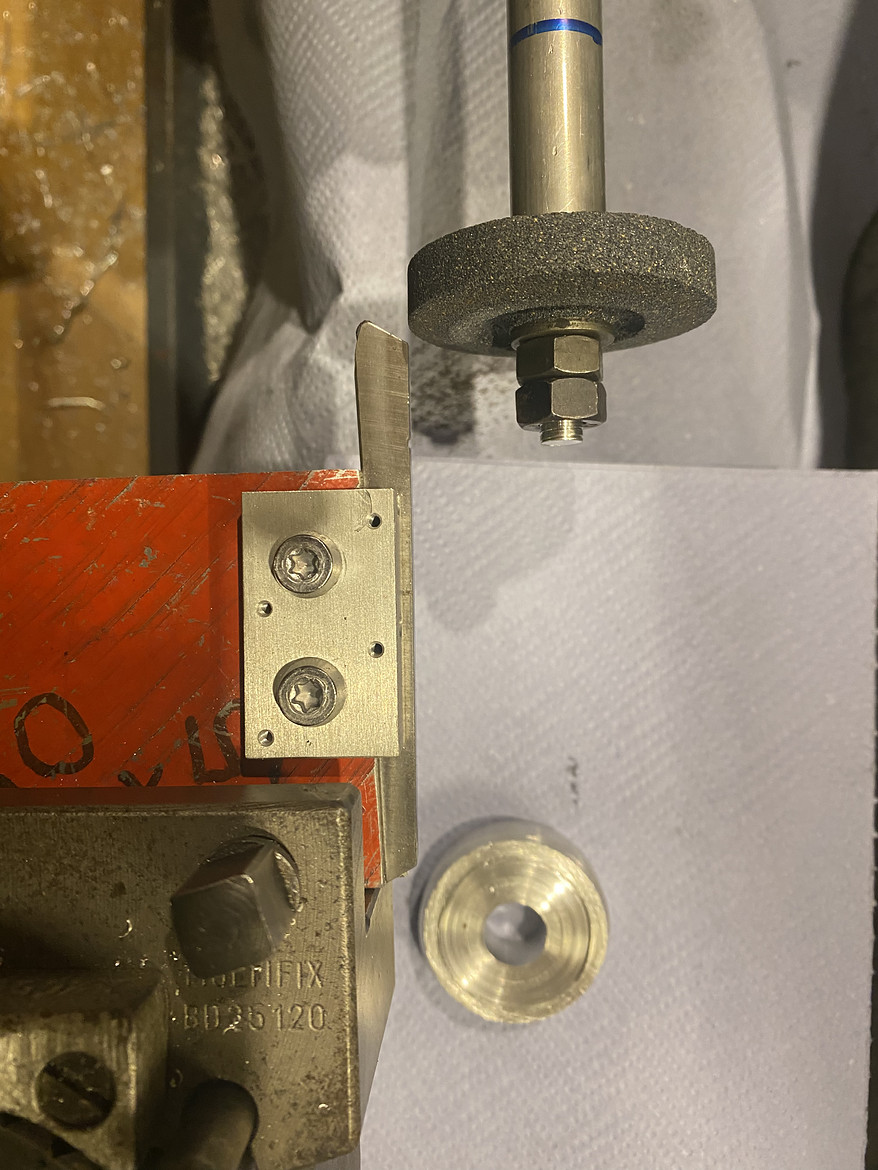

That would be Manitou forks, lots of XT, maybe some anodized Aluminium. And Magura brakes. Because Magura brakes are the best.

So. This time round I had to scratch the itch and buy back some of my childhood memorys.

My first "proper" mountainbike that I bougt new around 1991. I think.

Here is my only picture of it in 1993. I stumbeled across that picture while clearing my mom's flat.

Of course it had a set of "horns" bolted to the bar. You can't see it in the picture, but I did a lot of weight reduction to those, buy drilling tens of holes into them.

Then again - completely forgetting about the weight - I had to fit these wheel covers to the back. Because I had seen some famous rider in the magazine riding them tensions disks...

[OT] If you are wondering what the hell is going on in that picture: It's a german custom that on the last day in school the class stays in the building over night and prepares some kind of prank for the teachers. In this case some concrete brickage and - of course - water baloons... [/OT]

I really loved that bike back then. I learned the ropes of repairing your own bike. It had a shimano 200GS. Didn't last long. I had to replace the hubs soon.

The rear derailleur was ripped off at some point. And it was quite the hassle to get a replacement. A used XT one that I found in the ad section of our newsletter. Remember these?

I had to ride 20km to the next town to get it. And I had to borow that puny 20" foldable bike from my dad for the trip. No fun, that.

Anyhow. I managed to get my hands on a very nice example of on of those bikes for cheap. Ah, the wonders of the internet.

This is the beauty, as I got it a few weeks back. Very mint condition. No rust. No fading in the paint.

Just a glorious neon paint with dark splatters.

I love it.

The plan is to strip it completely. Then use all the stuff on it, my 13 year old self used to drool over bitd.

That would be Manitou forks, lots of XT, maybe some anodized Aluminium. And Magura brakes. Because Magura brakes are the best.

Last edited: