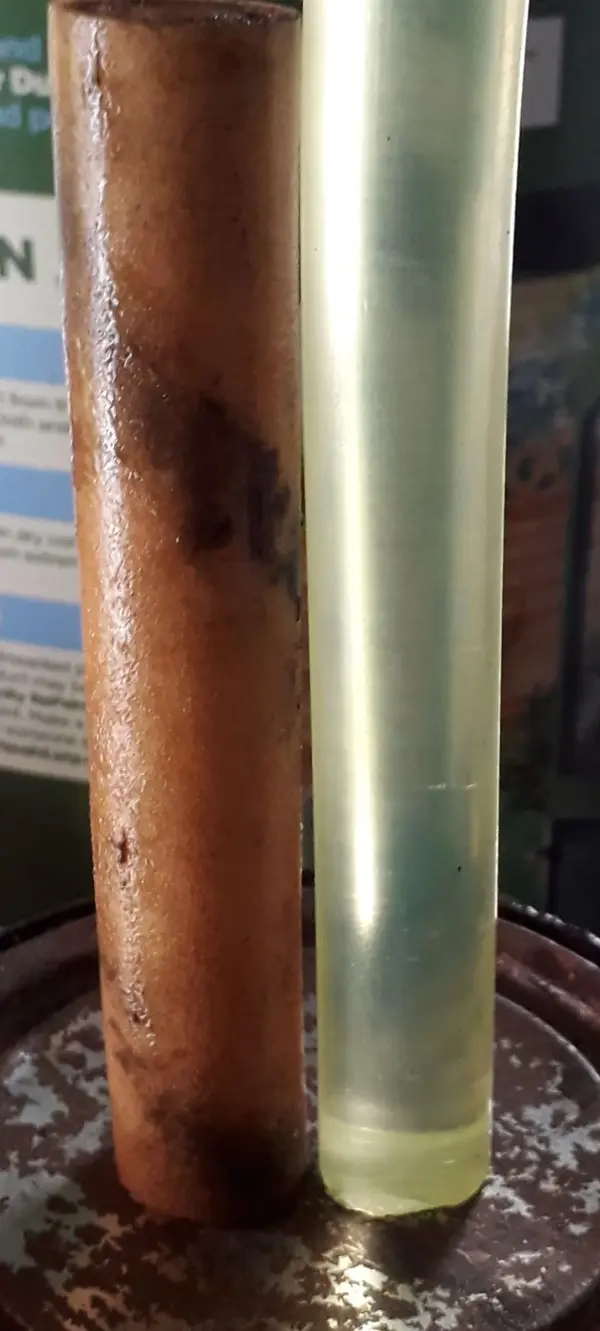

Hello all, don’t shoot me down if this is a dumb question/post - I’m reasonably new to this retro love thang...but I recently bought these and despite them being listed as having recent rebuild and new red elastomers and being ‘very soft’ they literally do not move. I’m limited in workshop knowledge/skill so I don’t want to mess too much but these have a spring one side and elastomers on the other? We’re conversions always just one sided? Spring, compression and rebound work great with the elastomer stack out. Drop the elastomers back in and you get maybe 1-2mm travel. Can anyone guide me on how to sort this or should I recontact the seller as these aren’t really what was listed. Any help or pointers appreciated. Thanks - pics

https://ibb.co/album/s5cgzb

https://ibb.co/album/s5cgzb