You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re-Anodising...

- Thread starter BerthaPog

- Start date

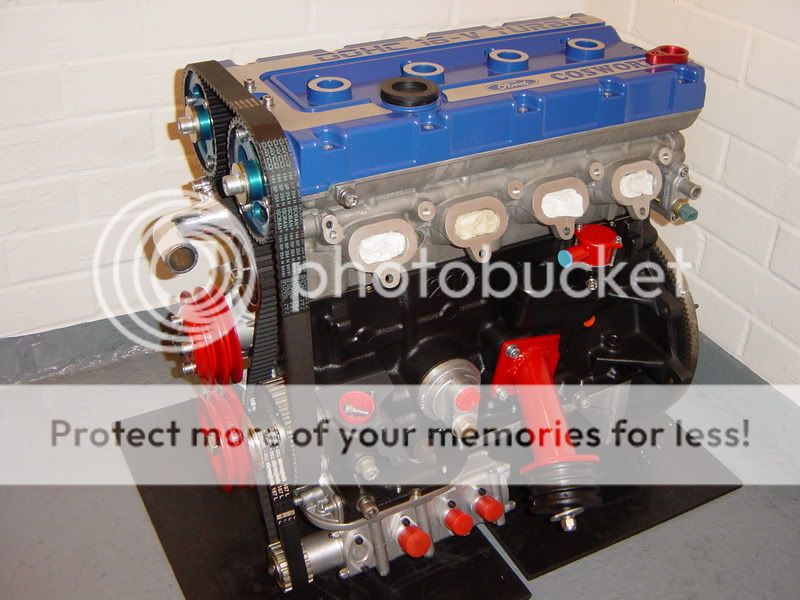

WD Pro":pxw4j8k2 said:A (modified) bike chassis'd Dax rush with a cosworth YB, it's not finished yet (surprise surprise

) taking bloody ages

Will post a few pictures from work tomorrow

WD

ooh two of my mates have daxi! ones a black bird engined crazy machine, and the others a rover v8. nutty little cars!

the black bird engined one has 6 forward and 6 reverse gears!

Yes I got hooked after wanting one a long time ago and then being taken around Oulton Park in Duncan Cowpers car :shock:

As you know a little on dax's, it's a round tube camber compensation chassis, with the rac cage and beefed up main tubes to handle the weight / torque of a tuned cossie lump. I got number 2 of (I think now) 4. Honda s2000, mine, vag turbo and then a rover V8.

Got called off site today but I will try and post some pictures after

WD

As you know a little on dax's, it's a round tube camber compensation chassis, with the rac cage and beefed up main tubes to handle the weight / torque of a tuned cossie lump. I got number 2 of (I think now) 4. Honda s2000, mine, vag turbo and then a rover V8.

Got called off site today but I will try and post some pictures after

WD

they truly are wonder full cars. the bike engined one tops out at 125 but does 0-60 in under 3........ :shock: dean the chap who owns it has 18 points on his license..

the v8 will spin the tyres in the dry up to 4th gear.... :shock: would do firth but a pretty long gear for cruising at 120...

the v8 will spin the tyres in the dry up to 4th gear.... :shock: would do firth but a pretty long gear for cruising at 120...

silverclaws

Senior Retro Guru

Re. Anodising, to change the colour all one has to do is strip the existing colour, I use household ammonia for this, but there is better stuff available formulated for the purpose. Anodising is simply an electrochemical process that creates a hard corrosion resistant coating that can be left as is, if it is just the mechanical properties that are required. But colour can be added, this done after the anodising is complete and takes the form of a dye which when the object is immersed in it, the porous surface of the anodised layer soaks up the dye giving the colour. After dying, the surface is sealed by boiling the object in distilled water.

With commercial anodisers, I expect it will seriously alter the cost and the finish if one strips the colour and prepares the object for anodising, simply take the colour out then polish away, remove scratches and any imperfection as these will show later when dyed.

I find it unusual that a commercial anodiser does not prepare the aluminium first, but if I am understanding this correct, just reanodises old colour intact, then bungs it in another colour dye. If this is the case, then colour shifts will happen and the results become unpredictable.

Time is money, prepare your metal yourself to get the best results.

I have just stripped the colour out of a NOS Pace chain rings, got rid of that manky grey ready for me to change the colour to red, also a NOS crud claw, cog hog and a couple of Tektro brake boosters. As I am doing it myself, I need to save up for the sulphuric acid, although I could do it at college, but refrain from doing so as one does not quite know the condition of the electrolite bath, how long it has been there and how much ally has been through it.

With commercial anodisers, I expect it will seriously alter the cost and the finish if one strips the colour and prepares the object for anodising, simply take the colour out then polish away, remove scratches and any imperfection as these will show later when dyed.

I find it unusual that a commercial anodiser does not prepare the aluminium first, but if I am understanding this correct, just reanodises old colour intact, then bungs it in another colour dye. If this is the case, then colour shifts will happen and the results become unpredictable.

Time is money, prepare your metal yourself to get the best results.

I have just stripped the colour out of a NOS Pace chain rings, got rid of that manky grey ready for me to change the colour to red, also a NOS crud claw, cog hog and a couple of Tektro brake boosters. As I am doing it myself, I need to save up for the sulphuric acid, although I could do it at college, but refrain from doing so as one does not quite know the condition of the electrolite bath, how long it has been there and how much ally has been through it.

Similar threads

- Replies

- 0

- Views

- 426

- Replies

- 24

- Views

- 2K

- Replies

- 14

- Views

- 3K

Latest posts

-

For Sale Dawes Super Galaxy fully loaded now £160

- Latest: lockedmyselfout

-

-

-

-