Gringotheking

Dirt Disciple

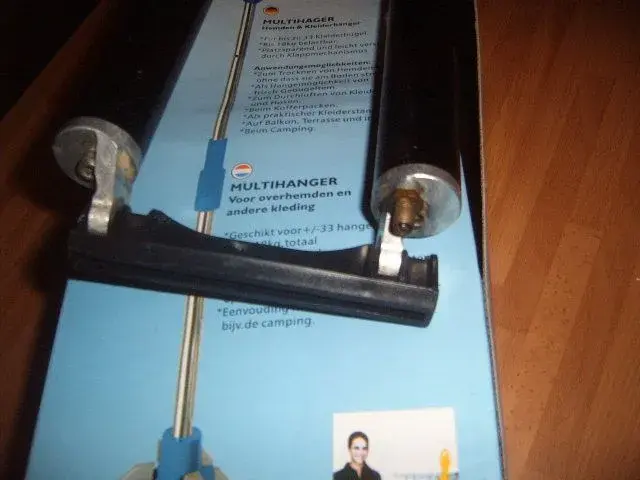

Hi all first post for me on here after a bit of info and help please, just bought a 1999 orange clockwork all original and mint for 50 quid with a spare set of wheels and road tyres! Decided that the forks were dog egg so bought some pace rc36 evo2's ( I think ). only cost 32 quid off flea bay they aren't holding any air at the mo. could someone tell me if they are rc36 evo2 proclass or otherwise and if they would be an easy fix or if I can use them without any air in them. A workshop manual would be greatly appreciated. I haven't seen the forks yet as I'm deployed away in a hot sandy place until next week but the missus sent me some photos. over to you guys.