Splatter Paint

Retrobike Rider

- Feedback

- View

Yep, not the cone, the cup. Anyone done it?

My Fire Mountain front hub was so bad I could hear it rumbling whilst it spun :facepalm: I thought I'd better investigate and found one cup totally pitted and useless. The hub is a cheap-o, original fitment Joytech. No replacement ones on eBay and I've never built a wheel, so I was a bit stuffed! I had a rummage under the bench (where all the really crap parts go to collect dust) and found a equally-cheap Joytech of modern age. I then performed the following:

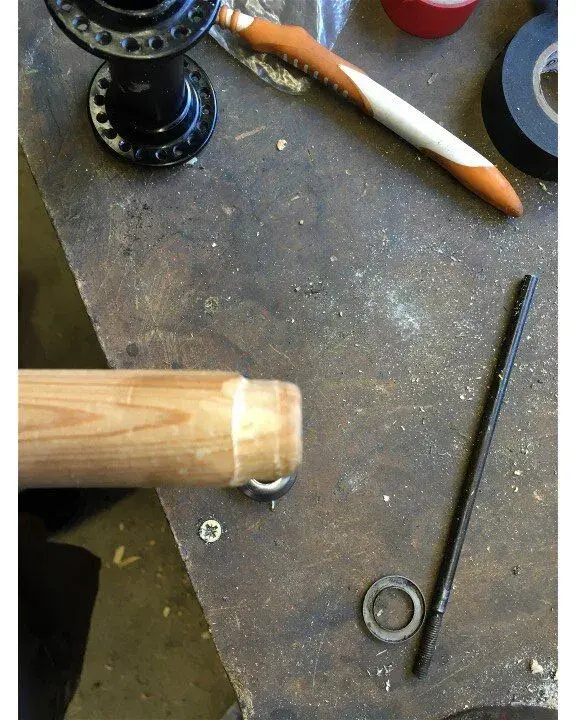

- Made a drift by cutting an old QR down

- Warmed the donor hub up with a hot air gun then drifted the cups out

- Warmed the built wheel up and drifted the damaged cup out

- Found the cups were different :facepalm: but thought I'd press on regardless - there was no going back!

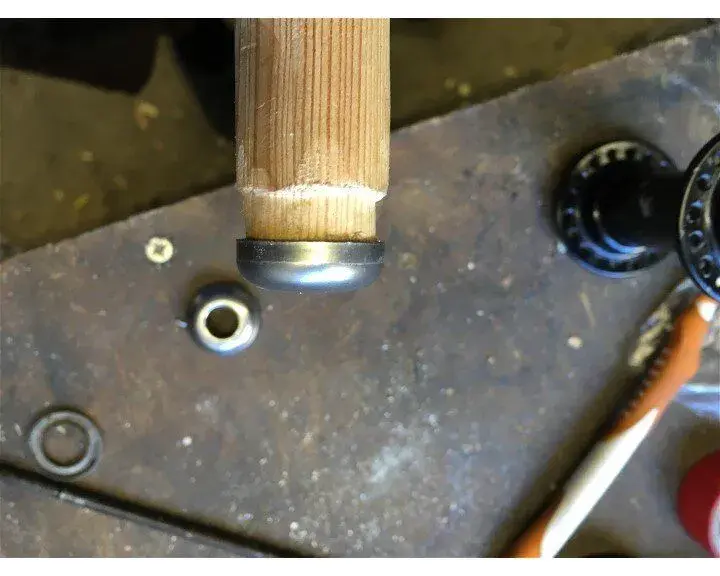

- Made a gert big wooden drift so the cup wouldn't get damaged

- Cleaned the hub up and greased the cup it just a fraction

- Warmed the hub up again and drifted the cup in. I measured the depth to the original bearing surface and tried to get that by drifting a bit then measuring with a micrometer.

- Rebuilt the hub with donor hub cones, I had to swap spacers and nuts around to get a 100mm OLN.

I was a little concerned it wouldn't seat properly, and the cup would be a little tilted but as the whole donor hub (I used the cones too) was low grade, it was never going to be perfect. However, once assembled, it is actually pretty good and was still fine and smooth after a 90 minute ride - sorted! I know these are not supposed to be service items and the hub should really be thrown away, but it is the lockdown and needs must I did the pressing in on the floor and put a block of wood under the hub so that the alloy wouldn't get damaged during fitment. No visible damage / marks were evident after I'd finished.

I did the pressing in on the floor and put a block of wood under the hub so that the alloy wouldn't get damaged during fitment. No visible damage / marks were evident after I'd finished.

After the lock-down I need to get some NOS hubs and get both wheels rebuilt, I am happy my little bodge worked for the time being. The main issue I can see is the stress imposed on the hub during the cone removal / fitment process. I'll keep an eye on the hub for cracks etc before every ride. I'm wondering whether to go Exage RM50 or something a little posher?

Pics are as follows:

1 Original cup

2 Nice 'n' square steel drift

3 Donor hub with cup pressed out

4 Replacement cup (yes, it isn't great but better than the other one )

)

5 Back of the cups (original on the left)

6 Broom handle drift

7 Cup fitted on

8 Mock-up of cone being drifted in (I didn't take photos of that as it was all really hot and a time-dependant)

My Fire Mountain front hub was so bad I could hear it rumbling whilst it spun :facepalm: I thought I'd better investigate and found one cup totally pitted and useless. The hub is a cheap-o, original fitment Joytech. No replacement ones on eBay and I've never built a wheel, so I was a bit stuffed! I had a rummage under the bench (where all the really crap parts go to collect dust) and found a equally-cheap Joytech of modern age. I then performed the following:

- Made a drift by cutting an old QR down

- Warmed the donor hub up with a hot air gun then drifted the cups out

- Warmed the built wheel up and drifted the damaged cup out

- Found the cups were different :facepalm: but thought I'd press on regardless - there was no going back!

- Made a gert big wooden drift so the cup wouldn't get damaged

- Cleaned the hub up and greased the cup it just a fraction

- Warmed the hub up again and drifted the cup in. I measured the depth to the original bearing surface and tried to get that by drifting a bit then measuring with a micrometer.

- Rebuilt the hub with donor hub cones, I had to swap spacers and nuts around to get a 100mm OLN.

I was a little concerned it wouldn't seat properly, and the cup would be a little tilted but as the whole donor hub (I used the cones too) was low grade, it was never going to be perfect. However, once assembled, it is actually pretty good and was still fine and smooth after a 90 minute ride - sorted! I know these are not supposed to be service items and the hub should really be thrown away, but it is the lockdown and needs must

After the lock-down I need to get some NOS hubs and get both wheels rebuilt, I am happy my little bodge worked for the time being. The main issue I can see is the stress imposed on the hub during the cone removal / fitment process. I'll keep an eye on the hub for cracks etc before every ride. I'm wondering whether to go Exage RM50 or something a little posher?

Pics are as follows:

1 Original cup

2 Nice 'n' square steel drift

3 Donor hub with cup pressed out

4 Replacement cup (yes, it isn't great but better than the other one

5 Back of the cups (original on the left)

6 Broom handle drift

7 Cup fitted on

8 Mock-up of cone being drifted in (I didn't take photos of that as it was all really hot and a time-dependant)