MuchAlohaNui

Senior Retro Guru

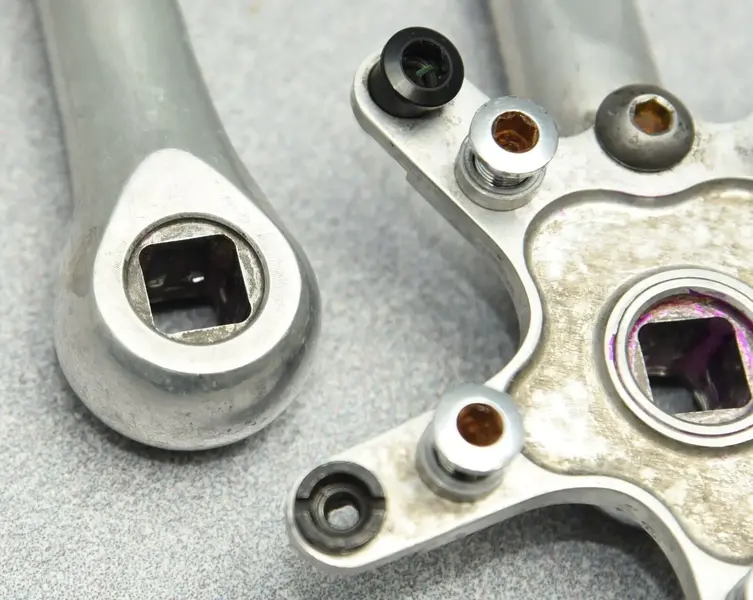

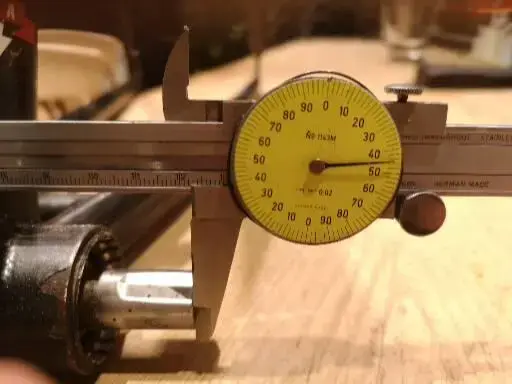

Is there any consideration regarding selection of bottom bracket spindle width for the very early model Grafton Speedstix? When these were produced by Topline (pre falling out / Grafton going their own way) there is something to do with needing to use a wider than usual spindle length due to how the crank arm square hole was manufactured; i.e. using a 113 mm spindle for Shimano cranks, but when switching to the Speedstix needing to go as long as 122 mm or so. Or was this for the Topline cranks only?

In the 1994 Grafton catalog here on Retro, there is no word of requiring a wider bb spindle. Of course, this information at this point is conjecture, so I am seeking clarity from those of you with experience with said cranks. Mahalo!

In the 1994 Grafton catalog here on Retro, there is no word of requiring a wider bb spindle. Of course, this information at this point is conjecture, so I am seeking clarity from those of you with experience with said cranks. Mahalo!