You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cook Bros. F-Type Crank Mold

- Thread starter Tomato

- Start date

27motorhead

Old School Grand Master

- Feedback

- View

Zero provenance. I wonder what @Caj Remtiw thinks to this???But at that price, you'd need some provenance to show it's from the factory, not an apprentice playing around with casting a copy of his crank arm in a foundry.

I'm not quite sure why we are discussing provenance, the tooling required to make this would probably cost knocking on for £10,000 & also require a F'king great forging machine. Why on earth would anyone spend that much money & effort to fake it (I was going to say forge a forging!).

Its an interesting curio but not worth the asking price.

Its an interesting curio but not worth the asking price.

Betsy

Old School Grand Master

Quite.. i used to make tooling around the same era these cranks were manufactured (in the days before CNC) we had a machine called an Alexander Die Sinker / Copier.

I would make a pattern of (lets say) the crank, then cast a PU mould around it, remove the pattern so i would have a negative of the crank cast into a square block of PU (basically the die but made in PU) i would then get a block of SG iron the same size as the block of PU.. the Alexander had 2x heads / chucks, side by side, one with a stylus and one with a machining cutter which were both exactly the same size.. both heads worked in unison so the stylus would be tracing the shape of the negative crank while the cutter was cutting it out of the block of SG leaving you with the tooling.

I would make a pattern of (lets say) the crank, then cast a PU mould around it, remove the pattern so i would have a negative of the crank cast into a square block of PU (basically the die but made in PU) i would then get a block of SG iron the same size as the block of PU.. the Alexander had 2x heads / chucks, side by side, one with a stylus and one with a machining cutter which were both exactly the same size.. both heads worked in unison so the stylus would be tracing the shape of the negative crank while the cutter was cutting it out of the block of SG leaving you with the tooling.

Betsy

Old School Grand Master

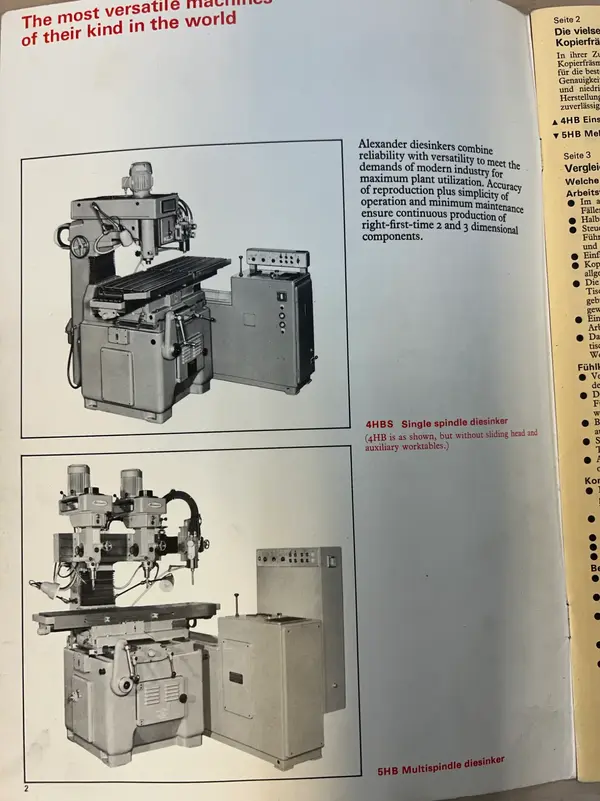

Morning @Lucidone .. it’s an Alexander 4HB

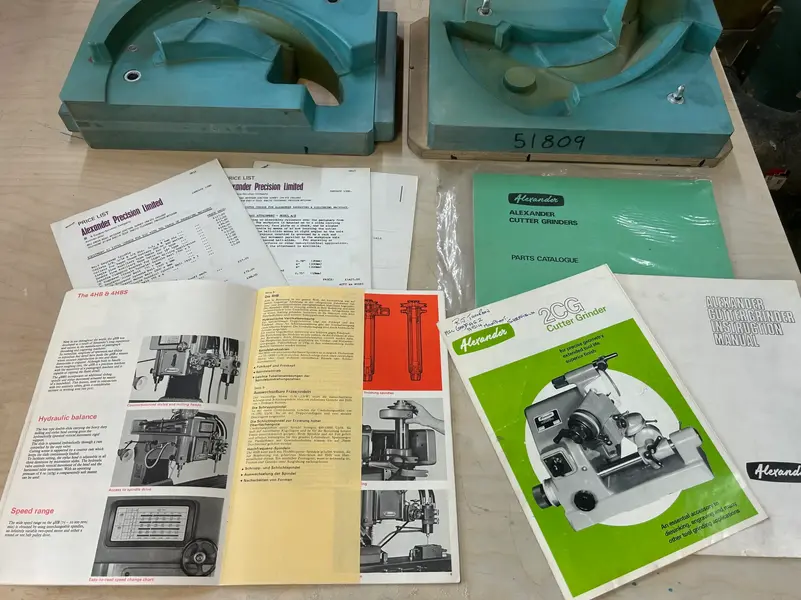

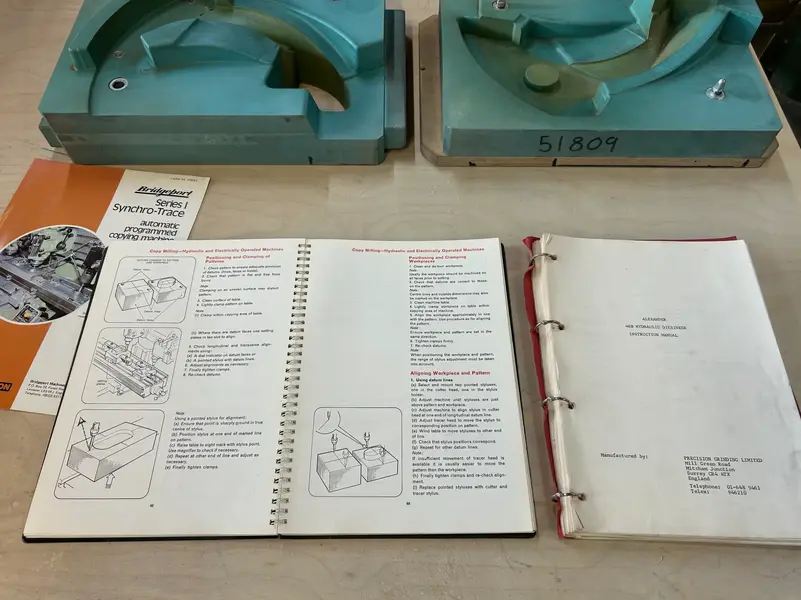

I’ve still got all the instructions manuals, catalogues, parts lists, original bill of sale and a die making instruction manual issued by the Engineering Industry Training Board for Engineering Craftsmen no less

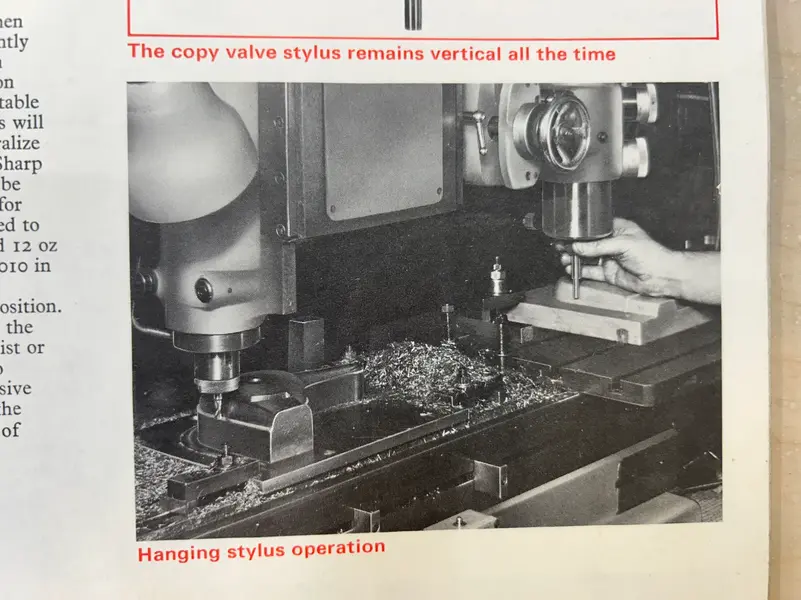

Operating the stylus

This is how the machine should look

..alas, it hasn’t sunk a die since Eclipse Magnetic outsourced its tooling in the 90s so it now resides in my machine graveyard

I’ve still got all the instructions manuals, catalogues, parts lists, original bill of sale and a die making instruction manual issued by the Engineering Industry Training Board for Engineering Craftsmen no less

Operating the stylus

This is how the machine should look

..alas, it hasn’t sunk a die since Eclipse Magnetic outsourced its tooling in the 90s so it now resides in my machine graveyard

Betsy

Old School Grand Master

It had a guard .. it’s a piece of hardboard, inserted into a piece of ply

Yes, you can use the stylus manually to plough off material then when you get close to finished size you can set the auto-feed and the bed moves left/right.. up/down with the stylus tracing the shape while the cutter creates the die.. when the Alexander has finished its process.. the tooling is covered in pic/contour lines which need grinding/polishing out by hand.. well, with the mini-grinders which connect to the airline.

Yes, you can use the stylus manually to plough off material then when you get close to finished size you can set the auto-feed and the bed moves left/right.. up/down with the stylus tracing the shape while the cutter creates the die.. when the Alexander has finished its process.. the tooling is covered in pic/contour lines which need grinding/polishing out by hand.. well, with the mini-grinders which connect to the airline.

Caj Remtiw

Old School Hero

That is one of the first handful of test "pressing's" of the Cook Bros. Racing F Crank. It was pressed in a 2000 ton hydraulic forging press. The first operation is to see if the shape turned out right/ correct  . More material than necessary is used in this phase so as not to forge a "semi-crank", that is why you see all the spill/ overlap around the arm. The production units just had a small lip that was bandsawed off being fixtured into the CNC mill for final machining.

. More material than necessary is used in this phase so as not to forge a "semi-crank", that is why you see all the spill/ overlap around the arm. The production units just had a small lip that was bandsawed off being fixtured into the CNC mill for final machining.

27motorhead

Old School Grand Master

- Feedback

- View

Thanks for this insight @Caj RemtiwThat is one of the first handful of test "pressing's" of the Cook Bros. Racing F Crank. It was pressed in a 2000 ton hydraulic forging press. The first operation is to see if the shape turned out right/ correct. More material than necessary is used in this phase so as not to forge a "semi-crank", that is why you see all the spill/ overlap around the arm. The production units just had a small lip that was bandsawed off being fixtured into the CNC mill for final machining.

Similar threads

- Replies

- 1

- Views

- 498