2manyoranges

Senior Retro Guru

- Feedback

- View

Right...you can readily get new axles and bearing rebuild kits for Penthouse mk4 pedals. And there's no tech manual or exploded diagram on the web. Grrr. There's a couple of breakdown threads....and they are Wrong.

You start by removing the end cap with a 5mm Allen Key. Simples.

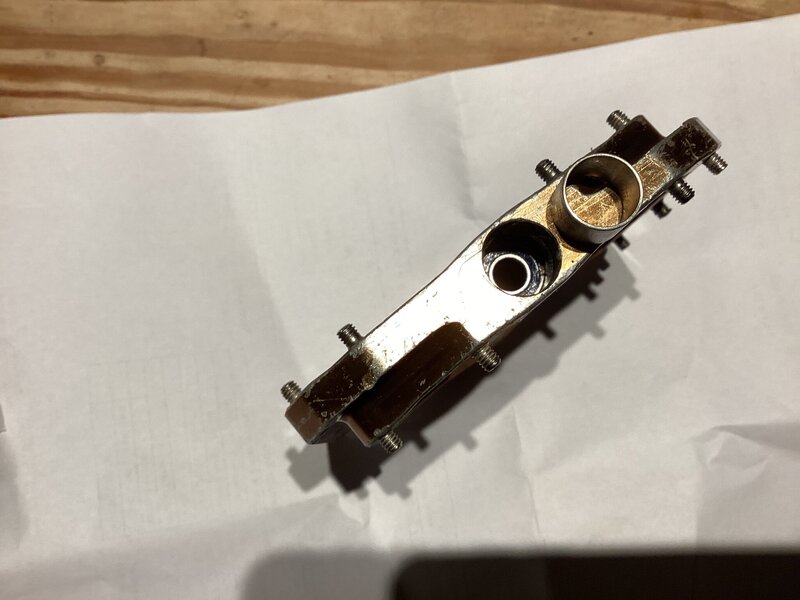

You then see a 10mm locknut which sits inside a raw aluminium housing. And the special 10mm 1/4 inch drive socket which you bought from Bergtec...doesn't fit. It just won't go in. The ally housing is too small. What no one says is that you have to get the alloy housing - which is simply a dedicated, loose section of tubing - out. You can try tapping the pedal on a bench, but that usually does not get it out. You need a blind bearing puller. Then it's incredibly simple to pull out the alloy housing - see photo - and then the socket goes in and fits perfectly on the locknut.

Pedal into vice. Undo locknut.

Pull out axle.

Then pick out the green seal at the inner end with a pick.

Then use a blind puller and slide hammer to extract the inner bushing (bushing 1).

Really difficult to extract with any other tool. Simple and quick with the right one.

Then drift out the tiny bearing at outer end with an 8mm allen key.

This leaves the small bushing (bushing 2) which sits behind the bearing.

For this, use a piece of 8mm solid aluminium rod as a drift, catching one side of the bush.

Drift this bushing out towards the outer end of the pedal.

Clean everything

Select chamfered end of small bushing 2, and insert this into the pedal.

Use the 10mm socket and soft hammer to drift this into the pedal.

You will feel it reach the bottom of its housing.

Then insert bearing, drifting it in with the wrong end of the 10mm socket.

DO NOT INSERT the ally housing tube at this point - you still need to get the nut on and tight.

Then attend to the inner end.

Large bushing gets drifted in with a long-nosed socket.

Some pedals have an O ring which goes in next.

Grease main green seal with silicon grease and insert by pressing in with fingers.

Grease entire length and insert axle.

Lock pedal axle in vice and drop small washer on outer end, over the top of the axle.

Wind on locknut with 10mm socket, tightening until you feel resistance, then back off 1/4 turn.

Crucial step: insert silver ally tubular housing (see photo)

Put anti-seize onto thread of black end cap.

Insert black end cap and tighten with 5mm Allen key.

All done.

Clear up.

Go ride.

You start by removing the end cap with a 5mm Allen Key. Simples.

You then see a 10mm locknut which sits inside a raw aluminium housing. And the special 10mm 1/4 inch drive socket which you bought from Bergtec...doesn't fit. It just won't go in. The ally housing is too small. What no one says is that you have to get the alloy housing - which is simply a dedicated, loose section of tubing - out. You can try tapping the pedal on a bench, but that usually does not get it out. You need a blind bearing puller. Then it's incredibly simple to pull out the alloy housing - see photo - and then the socket goes in and fits perfectly on the locknut.

Pedal into vice. Undo locknut.

Pull out axle.

Then pick out the green seal at the inner end with a pick.

Then use a blind puller and slide hammer to extract the inner bushing (bushing 1).

Really difficult to extract with any other tool. Simple and quick with the right one.

Then drift out the tiny bearing at outer end with an 8mm allen key.

This leaves the small bushing (bushing 2) which sits behind the bearing.

For this, use a piece of 8mm solid aluminium rod as a drift, catching one side of the bush.

Drift this bushing out towards the outer end of the pedal.

Clean everything

Select chamfered end of small bushing 2, and insert this into the pedal.

Use the 10mm socket and soft hammer to drift this into the pedal.

You will feel it reach the bottom of its housing.

Then insert bearing, drifting it in with the wrong end of the 10mm socket.

DO NOT INSERT the ally housing tube at this point - you still need to get the nut on and tight.

Then attend to the inner end.

Large bushing gets drifted in with a long-nosed socket.

Some pedals have an O ring which goes in next.

Grease main green seal with silicon grease and insert by pressing in with fingers.

Grease entire length and insert axle.

Lock pedal axle in vice and drop small washer on outer end, over the top of the axle.

Wind on locknut with 10mm socket, tightening until you feel resistance, then back off 1/4 turn.

Crucial step: insert silver ally tubular housing (see photo)

Put anti-seize onto thread of black end cap.

Insert black end cap and tighten with 5mm Allen key.

All done.

Clear up.

Go ride.

Attachments

Last edited: