TOMAS

Senior Retro Guru

So this popped up on the bay a few days ago and arrived today, I thought it would be a nice accompaniment to my Dekerf SL that I have. Prev owner (not sure if its anyone on here) said it had been repainted by Argos Bristol (think this is spelling) in this non-factory gunmetal grey and new decals added about 2 years ago, but sadly the lacquer is peeling quite badly in places, however i'm okay to live with that for now.

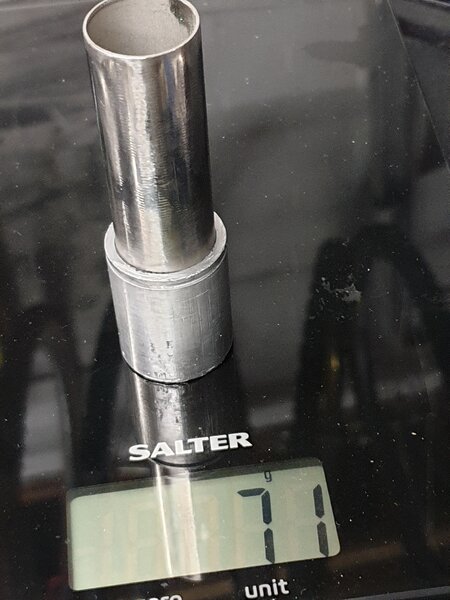

Here are a few pics of the bare frame, the prev owner also said that the the original Ti shock shaft has been replaced with stainless, obviously adds weight but possibly more durable and also the collet is a later one, again suspect this maybe an upgrade version, again these said to have been supplied by Dekerf himself. It comes in at 2kg at present, does anyone have any tips for removing the shock - spring and shaft? I assume its a case of unbolt the 2 bolts from the lower section of wishbone, undo the collet clamp, remove the circlip and then it should all just slide out from the bottom? I purely want to do this to be nosey before I build it, just interested to see the simple workings within...

Here are a few pics of the bare frame, the prev owner also said that the the original Ti shock shaft has been replaced with stainless, obviously adds weight but possibly more durable and also the collet is a later one, again suspect this maybe an upgrade version, again these said to have been supplied by Dekerf himself. It comes in at 2kg at present, does anyone have any tips for removing the shock - spring and shaft? I assume its a case of unbolt the 2 bolts from the lower section of wishbone, undo the collet clamp, remove the circlip and then it should all just slide out from the bottom? I purely want to do this to be nosey before I build it, just interested to see the simple workings within...