I was asked to make a couple of replacement RC100 stem units by another member. One at 90º 115mm, the other 100º 100mm.

As someone who designs and makes stuff for a living, I didn't want to completely copy the Pace stem, the original design is their IP.

So this is all TIG welded, no brazing, and uses a Columbus steerer tube, rather than the Reynolds of the original:

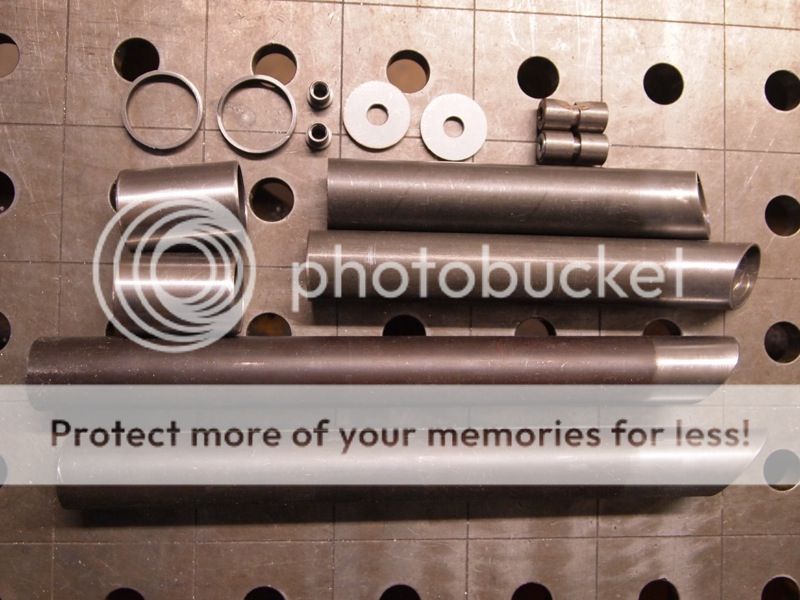

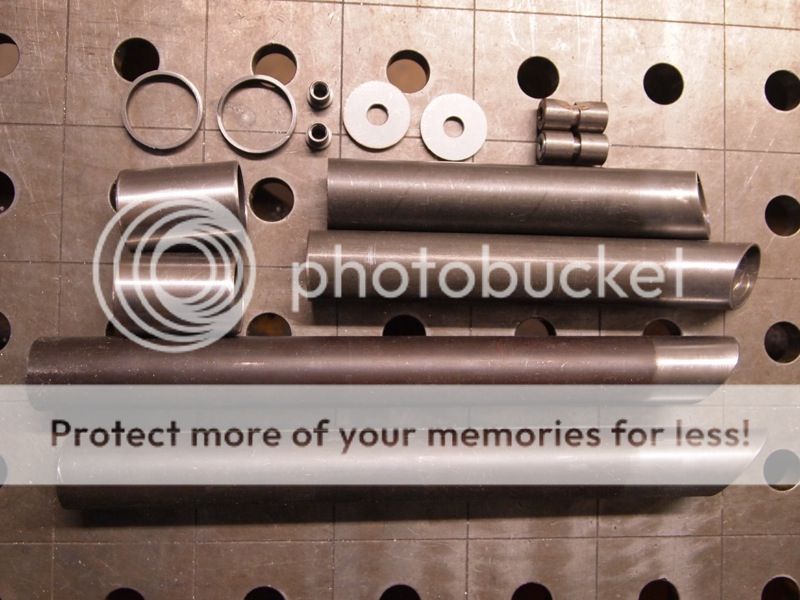

2 sets of parts cut:

-Columbus steerer tubes,

-Stem sections 1" x 0/049" seamless 4130,

-Stem clamps 1.125" x 0.058" 4130,

-Headset rings 1.125" x 0.058" 4130,

-Stem clamp bolt units,

-Thick 4130 washers,

-M6 threaded inserts.

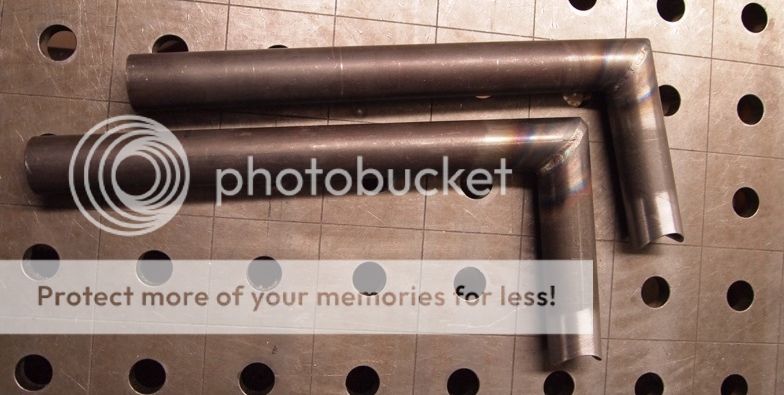

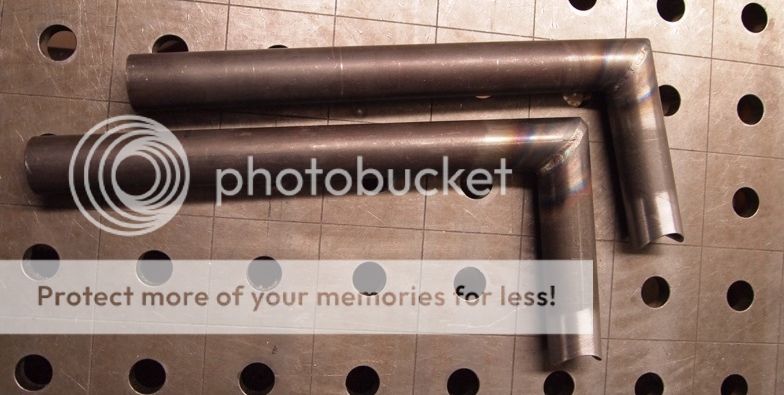

Welded at 90º, marked up to mitre the clamp section:

Bar clamp mitre cut on mill:

All held square, ready for welding:

Clamp and headset collar tacked on:

Clamp and headset collars welded:

Bottom end cut to length (212mm from headset collar), end cap welded on including M6 threaded insert:

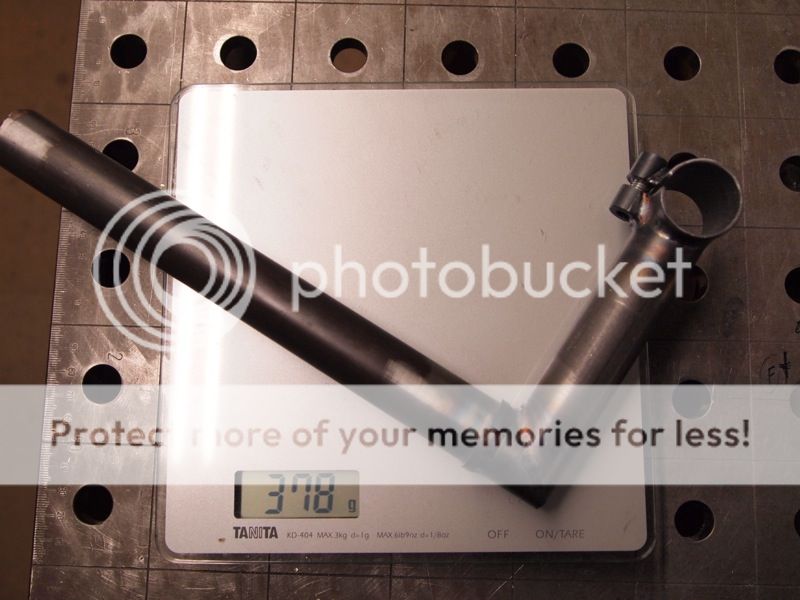

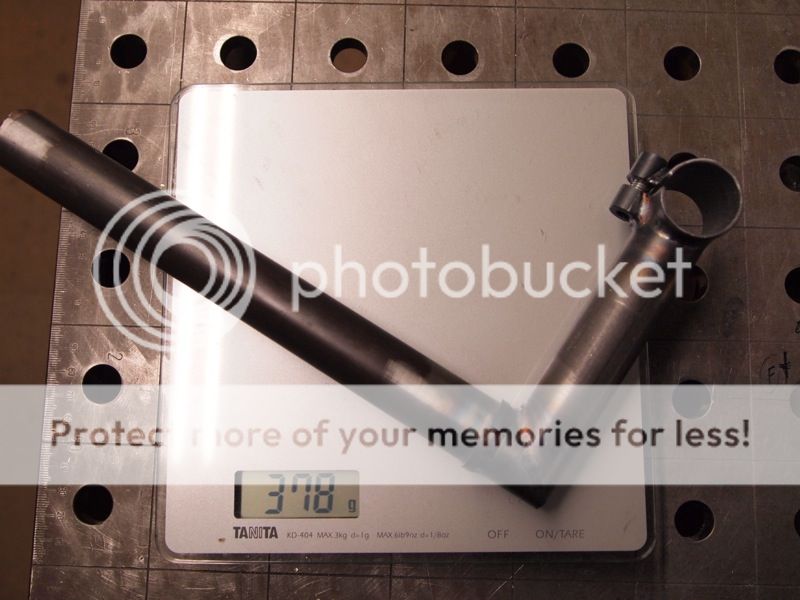

Cut clamp slot, file around bottom weld, deburr...All done:

Came out a bit lighter than the original which was 462g incl paint), so 'stem' section may have been heavier gauge, 0.058"?

All the best,

As someone who designs and makes stuff for a living, I didn't want to completely copy the Pace stem, the original design is their IP.

So this is all TIG welded, no brazing, and uses a Columbus steerer tube, rather than the Reynolds of the original:

2 sets of parts cut:

-Columbus steerer tubes,

-Stem sections 1" x 0/049" seamless 4130,

-Stem clamps 1.125" x 0.058" 4130,

-Headset rings 1.125" x 0.058" 4130,

-Stem clamp bolt units,

-Thick 4130 washers,

-M6 threaded inserts.

Welded at 90º, marked up to mitre the clamp section:

Bar clamp mitre cut on mill:

All held square, ready for welding:

Clamp and headset collar tacked on:

Clamp and headset collars welded:

Bottom end cut to length (212mm from headset collar), end cap welded on including M6 threaded insert:

Cut clamp slot, file around bottom weld, deburr...All done:

Came out a bit lighter than the original which was 462g incl paint), so 'stem' section may have been heavier gauge, 0.058"?

All the best,