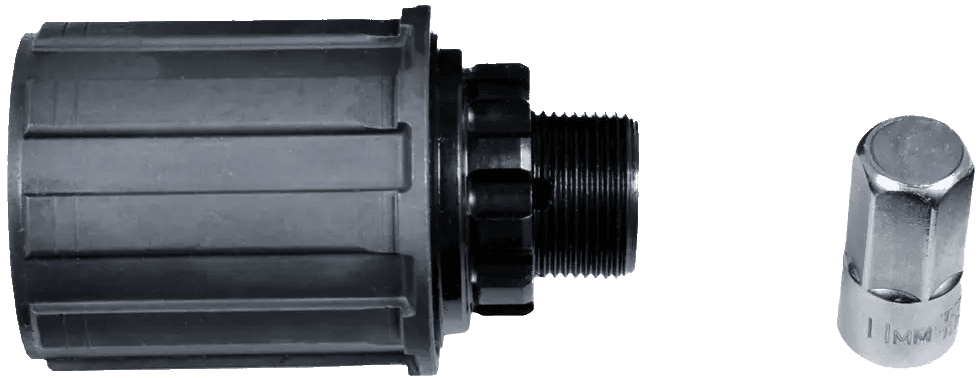

Scratching my head over this one and googling hasn’t helped greatly. I’ve got this Ritchey-branded hub pictured. It’s old, don’t know how old, but looked unused on fitting last year. In use the freehub seemed not to spin properly - the sound is off- so I thought maybe old grease has gone hard: I’ll remove and give it a lube.

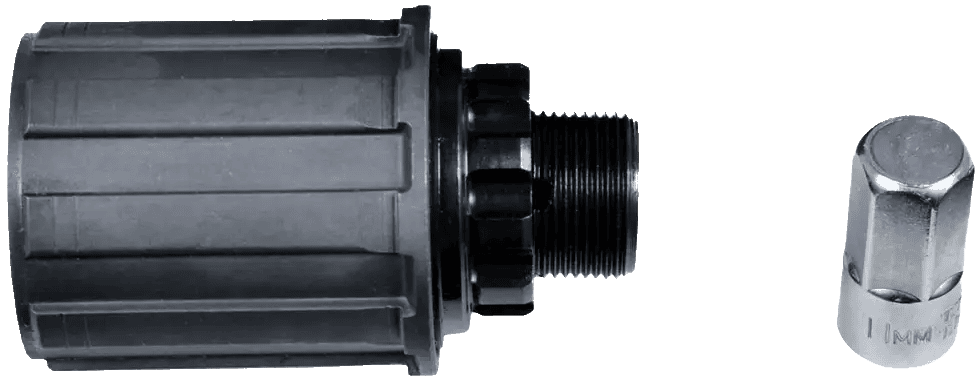

The freehub hole, from the driveside, is too large for a 10mm hex and too small for a 12mm. I can’t actually see any hex shape in there. However, from the non-driveside, a 12 hex locates snuggly. I guessed I’d need to turn it clockwise to unscrew from the non- driveside but, even with a BIG lever, it’s not turning. I used so much force that the spokes started pinging. It’s a borrowed torque wrench and looks very expensive so I don’t want to force it and risk damage. I tried anti-clockwise from the non driveside too- but with less force.

Thinking I need to know what I’m dealing with before getting super brutal with it. Any thoughts please?

The freehub hole, from the driveside, is too large for a 10mm hex and too small for a 12mm. I can’t actually see any hex shape in there. However, from the non-driveside, a 12 hex locates snuggly. I guessed I’d need to turn it clockwise to unscrew from the non- driveside but, even with a BIG lever, it’s not turning. I used so much force that the spokes started pinging. It’s a borrowed torque wrench and looks very expensive so I don’t want to force it and risk damage. I tried anti-clockwise from the non driveside too- but with less force.

Thinking I need to know what I’m dealing with before getting super brutal with it. Any thoughts please?

Attachments

Last edited: