Dr Dremel

Fat Chance Fan

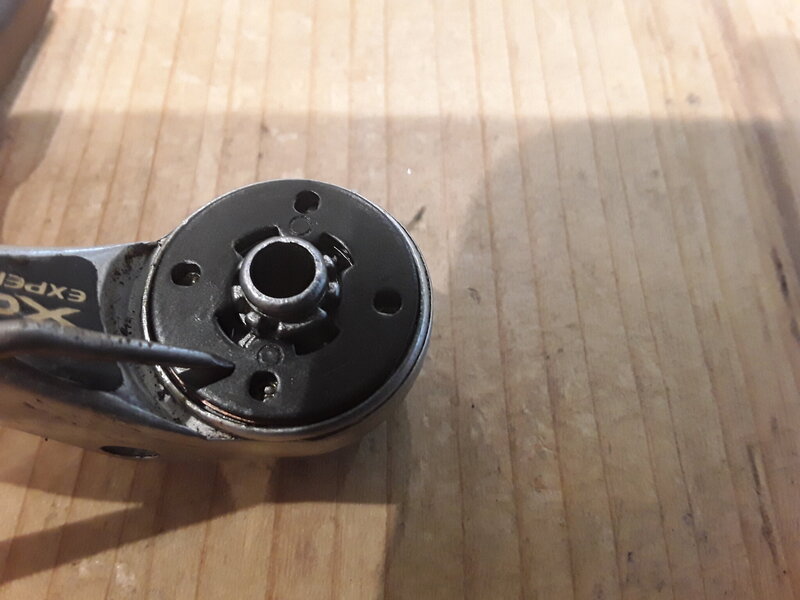

Really dont know what this talk about drilling an extra hole is about? Have you not disassembled one? There is an extra hole, it was just not intended for an extra gear, it´s for the spring in the lever to hook into. That´s where the "extra click" is coming from. Yes it´s not 100% spaced correctly and because the end of the spring is poking through not 100% as deep as the other dimples, and it´s just on one side of the clicky ring, but if it´s good enough for Kona to spec thumbies with an XTR rear hub as OEM, then it´s good enough for me.

For a more affirmative click you can dremel an extra dimple on the other side, but it´s not strictly necessary IMHO (I never bothered) as the click is on the end of the travel of the lever anyway.

For completeness: Same goes for 6sp thumbies with 7sp cassettes. The play in the upper pulley of Shimano RDs will take care of the slight difference in spacing.

For a more affirmative click you can dremel an extra dimple on the other side, but it´s not strictly necessary IMHO (I never bothered) as the click is on the end of the travel of the lever anyway.

For completeness: Same goes for 6sp thumbies with 7sp cassettes. The play in the upper pulley of Shimano RDs will take care of the slight difference in spacing.