Good evening all,

I thought I would post what I have been up to yesterday and today as it may assist someone. I am not sure I have seen the following tip on RB.

I am in the process of cleaning and minimally refurbing a Raleigh ProRace which I got last week. The bike was really dirty but luckily the previous owner had been liberal with the oiling process. All the dirt was oil related and, although difficult to remove, what lay below was in good condition.

The stripping process went well, and the only parts which needed replaced were the BB and headset (oh no - not again!!!!). I was able to remove the HS and the BB on the non-drive side very easily. The drive side BB fixed cup was a different story.

I had a few attempts yesterday with an appropriate spanner but, having done this before, the spanner shows some signs of abuse. I realised that the cup was the only part of the frame that over-oiling had not helped. I had a look at Sheldon and found a BB fixed cup remover design using a nut and bolt and some washers. I spent 2 hours trying this yesterday with the result being a sore hand. I followed the directions to the letter but it failed. The only thing which may not have been right were the washers - i managed to bend two washers into the axle hole with the pressure of the nut. It was super tight but would not move - I was sweating with the pressure i exerted on my tools!

Having given up on this tactic, I decided to soak it in WD40 overnight, with the options for today being - try both tactics again or take it to the LBS tomorrow. This morning I squirted GT85 into the BB shell.

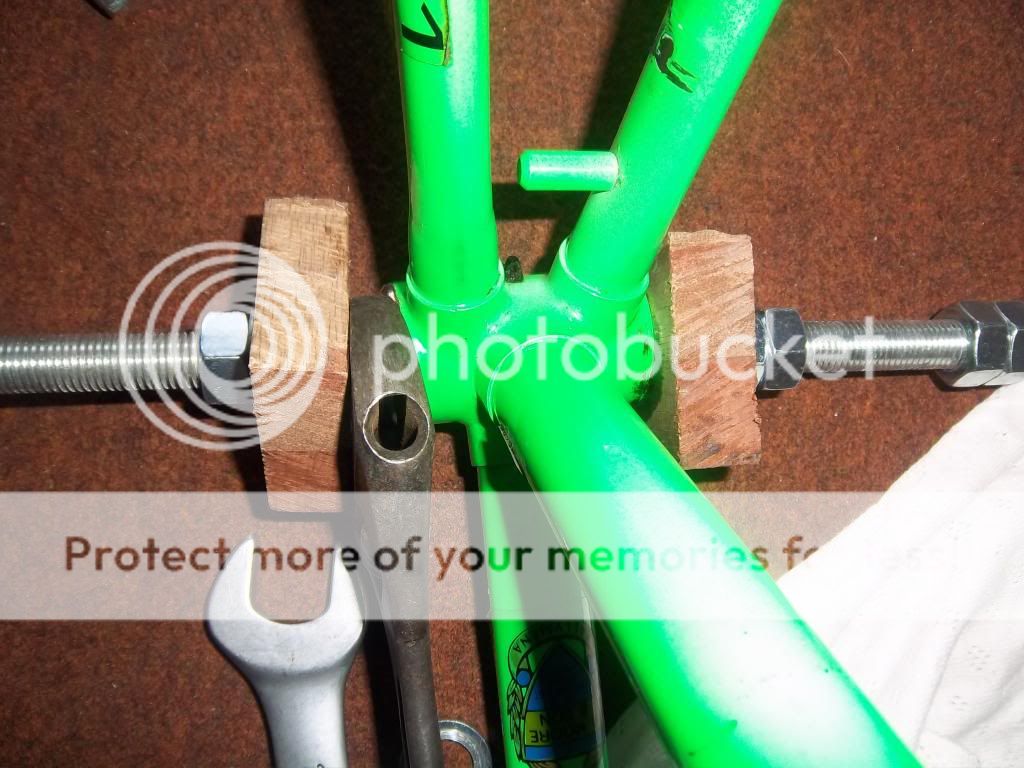

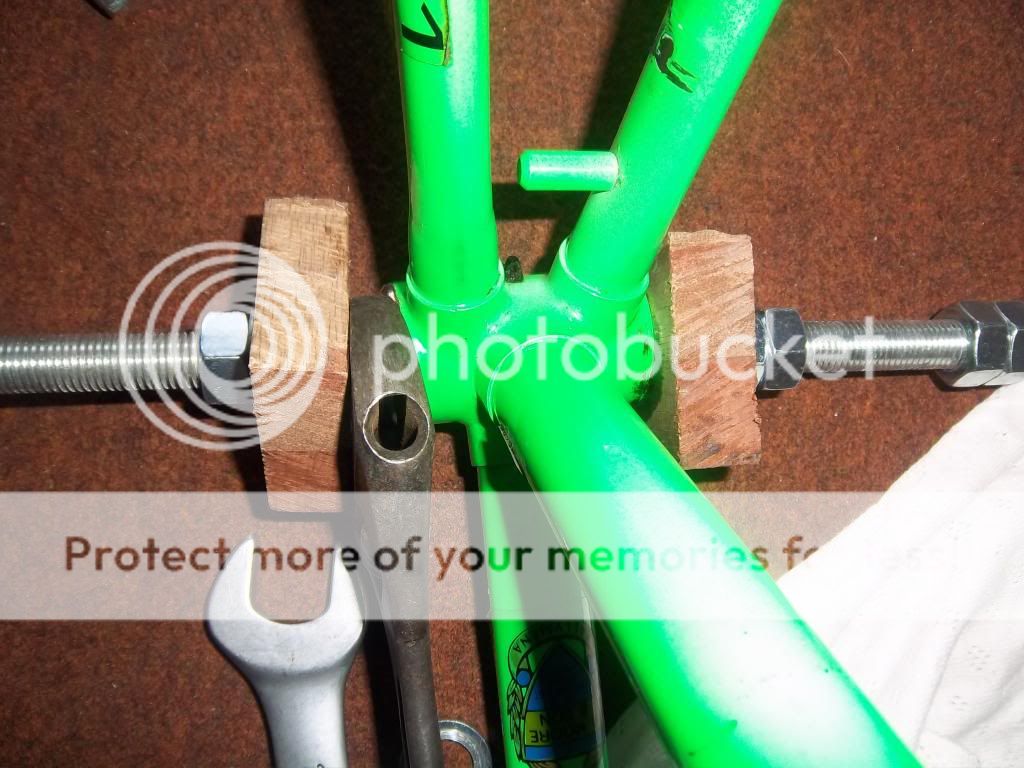

This afternoon I decided to have another try. Yesterdays options both failed again and I remembered something tips which I had read yesterday - mostly attach the tools securely to the cup. I pondered this and came upon a solution using my homemade headset press.

I was able to clamp a large shifting spanner onto the cup and tap it with a hammer to release the cup. I was rather pleased with my efforts!!!

Here are pics of the HS press in operation -

I hope this helps someone.

On a final note, it seems that my pondering actually works sometimes!!!

Richard

I thought I would post what I have been up to yesterday and today as it may assist someone. I am not sure I have seen the following tip on RB.

I am in the process of cleaning and minimally refurbing a Raleigh ProRace which I got last week. The bike was really dirty but luckily the previous owner had been liberal with the oiling process. All the dirt was oil related and, although difficult to remove, what lay below was in good condition.

The stripping process went well, and the only parts which needed replaced were the BB and headset (oh no - not again!!!!). I was able to remove the HS and the BB on the non-drive side very easily. The drive side BB fixed cup was a different story.

I had a few attempts yesterday with an appropriate spanner but, having done this before, the spanner shows some signs of abuse. I realised that the cup was the only part of the frame that over-oiling had not helped. I had a look at Sheldon and found a BB fixed cup remover design using a nut and bolt and some washers. I spent 2 hours trying this yesterday with the result being a sore hand. I followed the directions to the letter but it failed. The only thing which may not have been right were the washers - i managed to bend two washers into the axle hole with the pressure of the nut. It was super tight but would not move - I was sweating with the pressure i exerted on my tools!

Having given up on this tactic, I decided to soak it in WD40 overnight, with the options for today being - try both tactics again or take it to the LBS tomorrow. This morning I squirted GT85 into the BB shell.

This afternoon I decided to have another try. Yesterdays options both failed again and I remembered something tips which I had read yesterday - mostly attach the tools securely to the cup. I pondered this and came upon a solution using my homemade headset press.

I was able to clamp a large shifting spanner onto the cup and tap it with a hammer to release the cup. I was rather pleased with my efforts!!!

Here are pics of the HS press in operation -

I hope this helps someone.

On a final note, it seems that my pondering actually works sometimes!!!

Richard