lrh

Senior Retro Guru

Firstly thanks to the writer of this guide who provided inspiration and a couple of useful tips: http://www.allankelly.info/servicingthumbies.html

(EDIT: I notice that guide has gone)

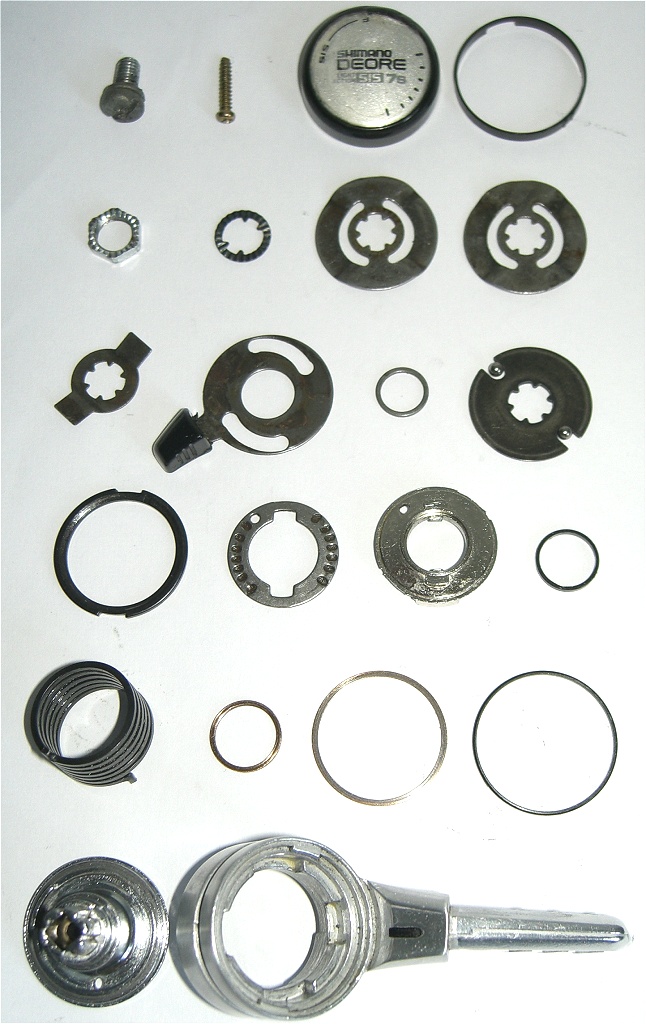

I wouldn't have guessed that the top cap is screwed on from underneath and the spindle nut has a left-hand thread. However when I came to re-assemble my shifters I found that guide lacking in detail and pictures. After a lot of trial and error I figured it out and decided to do more detailed build-up guide.

For clarity my guide shows how to build up both shifters from base parts, which means you can just pull yours apart without having to remember where everything goes. You can also follow the steps in reverse to safely take a shifters apart without bending or snapping anything.

These are MT62 Deore II/DX thumbshifters but the M732 Deore XT are almost identical internally, only the right-hand shifter adds a tiny bearing at the base of the spindle (see page 3 for a pic, thanks Matthias). I've also rebuilt Mountain LX thumbshifters recently and the info here should cover you for those as well.

Note: I assembled the shifters without grease purely to make the pictures clear. You should cover everything liberally with grease.

Let me know your question, comments, experiences

Cheers, Lawrence

(EDIT: I notice that guide has gone)

I wouldn't have guessed that the top cap is screwed on from underneath and the spindle nut has a left-hand thread. However when I came to re-assemble my shifters I found that guide lacking in detail and pictures. After a lot of trial and error I figured it out and decided to do more detailed build-up guide.

For clarity my guide shows how to build up both shifters from base parts, which means you can just pull yours apart without having to remember where everything goes. You can also follow the steps in reverse to safely take a shifters apart without bending or snapping anything.

These are MT62 Deore II/DX thumbshifters but the M732 Deore XT are almost identical internally, only the right-hand shifter adds a tiny bearing at the base of the spindle (see page 3 for a pic, thanks Matthias). I've also rebuilt Mountain LX thumbshifters recently and the info here should cover you for those as well.

Note: I assembled the shifters without grease purely to make the pictures clear. You should cover everything liberally with grease.

Let me know your question, comments, experiences

Cheers, Lawrence