Re:

PEDDLING MOUNTAIN BIKES

By Deseret News Apr 1, 1990, 12:00am MST

Jerry Spangler, Staff Writer

If you don't yet have a mountain bike hanging up in your garage, you may soon find yourself in the minority.

Six years ago, the market for mountain bikes represented less than 1 percent of all bicycles sold. Last year, of the 12 million bicycles sold in the United States, 65 percent were mountain bikes.In Utah, almost nine out of every 10 bikes sold are mountain bikes.

Now, the born-and-bred-in-America Easton Aluminum is out to make Utah the mountain bike manufacturing capital of the world. At least when it comes to aluminum mountain bikes.

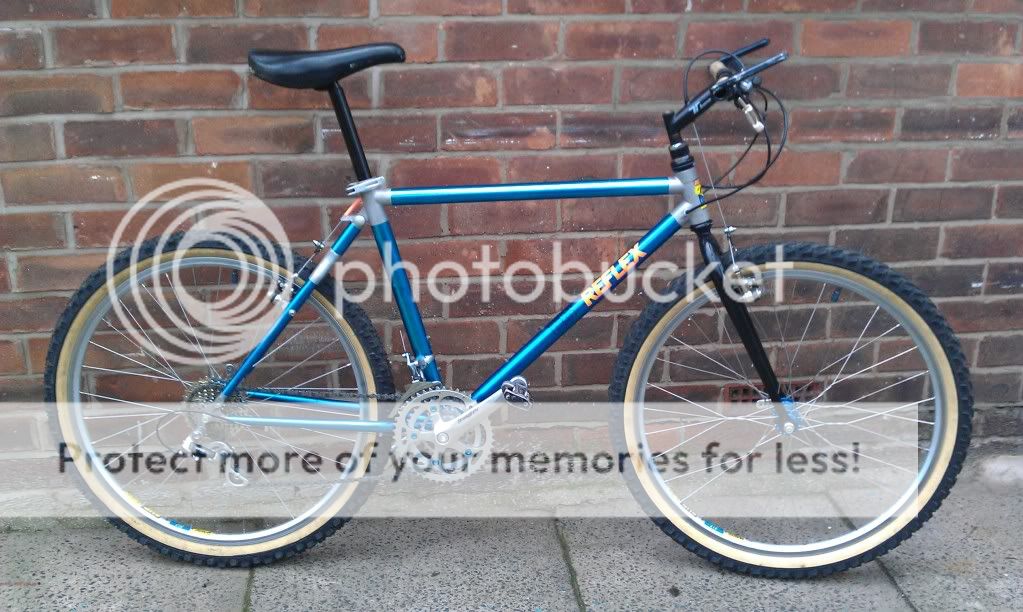

Easton Aluminum's subsidiary, Reflex, is now in its third year of marketing a state-of-the-art aluminum mountain bike that company officials say is at the top of a very competitive heap.

Comparing a Reflex to a regular mountain bike is sort of like trying to compare a Mercedes-Benz automobile and a Hyundai. "No comparison," boasts Mike Hillis, Reflex president.

To discriminating cyclists, Reflex is fast becoming the Mercedes of the bicycle industry, Hillis said. And so far, there are enough of those discriminating customers out there to make Reflex bikes some of the hottest - and most hard-to-find - bikes on the market.

In its 40 years of business, Easton Aluminum has developed a real knack for identifying a small market and then dominating that niche. Like archery products.

Easton's Salt Lake plant is a recognized world leader in the production of aluminum arrow shafts, producing up to 70,000 shafts a day. The same thing happened with aluminum baseball bats.

"We pioneered the aluminum bat," Hillis said, "and now we are the market leader because we found a niche and dominated it."

Easton has used its superior technological advantages to also dominate in other market niches, like ski poles, tent poles and snowshoes.

But can a superior raw material translate into a good, finished high-tech product like a mountain bike? After all, ski poles designed to color-coordinate with ski parkas are one thing. Bicycles are something totally different.

"The bicycle line is product-oriented where we can really make a difference in the market," Hillis said. "Aluminum is significantly better than steel, and our technology enables us to make a mountain bike that is both light and strong."

In fact, Hillis said Easton's higher-end bicycle frames are constructed of the strongest aluminum ever engineered - a so-called E9 aluminum alloy unequaled by any other aluminum manufacturer. It's the same aluminum used in the space program.

Hillis admits the Reflex bicycle line is a departure, of sorts, for Easton. Traditionally, Easton has manufactured a basic aluminum product that is then sold to other companies, who in turn put their own logos and distinctive accessories onto the product.

The Reflex bicycle offers a finished product no other bicycle company currently offers.

Given the company's track record for exploiting market niches, Easton and Reflex are undoubtedly seeking nothing short of the domination of the aluminum bicycle market.

Easton's experience with bicycle frames is nothing new. Other companies for years have been using Easton Aluminum tubing for their bicycle frames. Easton tubing has been popular among competitive riders for some time, again because of its light weight and strength.

But Easton watched in frustration as other bicycle companies would take aluminum tubing and try to mesh the aluminum with traditional steel-frame technology. Most would try bonding the aluminum to steel as they had done with steel frames.

"They weren't optimizing the advantages of aluminum over steel," Hillis said, "and the result was a product that could have been a whole lot better." The highest-strength aluminum can't be welded; it must be bonded. And that's where Easton's technology comes in.

About four years ago, Easton told the bicycle manufacturers, "Look, if you guys aren't going to do it right, we're going to do it ourselves."

And they did. This year, some 10,000 mountain bikes will roll off the assembly line at Easton's manufacturing plant at the International Center west of the Salt Lake International Airport. They range in retail price from about $600 to $2,000.

Unlike other aluminum bikes on the market, the Reflex bike has cast-aluminum brackets, lugs and headsets, and are each handmade.

The Reflex bicycle scarcely makes a dent in an annual market of 12 million bikes sold. But it has found a niche.

"We're a little player in a great big market," Hillis admits. "Yet we're making bikes as fast as we can, and we can't fill all the orders we have."

Currently, the Salt Lake plant makes 40 to 50 bikes a day with a capacity for 120 to 130 bikes a day. But Easton can't get enough top name-brand components. The best components are all manufactured in foreign countries, and supplies are limited.

Hillis emphasizes that Easton's venture into the bicycle market is not an attempt to dominate the entire bicycle market. Rather, it is to dominate a small portion of that market that wants a high-tech, sophisticated product and is willing to pay more to get it.

Most Reflex customers have owned at least one or two mountain bicycles previously, and most are extremely knowledgeable about the geometry and aero-dynamics of bicycles.

Easton's higher-end bikes feature an aluminum core frame covered with a high-strength carbon that makes it not only the strongest aluminum bike on the market, but dampens the effects of road vibrations. It's something a beginning rider could never discern, but one of importance to experienced riders.

"We're not trying to sell to beginning riders at all," Hillis said. "Some of our high-end bikes are real space-age stuff."

It's probably just as well. It would be nearly impossible for Easton to compete on the lower end with foreign manufacturers. About 90 percent of all bicycles sold in the United States are manufactured in Taiwan, Japan or other Far Eastern countries where labor costs are much lower. Most of those manufactured in the United States are custom orders or small operations.

Easton has capitalized on the fact that the Reflex bicycle represents the best in cutting-edge American technology. "People seem to like the fact it was made in the USA," Hillis said. "They immediately see it as more reliable."

Some other aluminum bikes are manufactured in the United States (some with Easton tubing), but Hillis said the manufacturers still employ the old steel technology that prevents them from using the strongest aluminum possible, Hillis said.

As with any trend, there's a possibility the current mountain bike boom will turn bust. But Easton uses the same basic equipment to manufacture the bicycle tubing as it does to make aluminum arrow shafts or ski poles.

A downturn in the bicycle market simply means a refocusing of the same technology on other aluminum product markets, Hillis said.

In the meantime, Easton will continue to ride the bicycle craze as much as it can. And as more and more Americans get into bicycling, more and more will become experienced riders looking for a better product.

"Cyclists can take a cheap bike only so long until they either hang it up or they go buy a quality product," Hillis said.

And the Reflex will be there when they do.